Luxury Knit is the top knitwear manufacturer in the USA. This company is known for using advanced technology. It also makes high-quality knitwear. Many sweater manufacturers usa, like Ohio Knitting Mills, Straus Knitting Mills, Royal Apparel, and Tailored Industry, make great knitwear too. These knitwear manufacturers make products that follow strict rules. The knitwear sector in the USA has many manufacturer choices. Each one has special strengths for brands that want good partners.

Key Takeaways

Top U.S. knitwear manufacturers use good natural fibers and skilled work. This makes their products strong and comfortable. Advanced technology helps them make custom knitwear quickly. They also use eco-friendly ways to make products. Customers can pick colors, patterns, and fits for their knitwear. This makes each product special to their style. Sustainability is important. Many manufacturers use organic materials and try to waste less. They also treat workers fairly to help people and the planet. Good communication with manufacturers is important. It helps get better quality, faster delivery, and more custom choices.

What Makes Top Knitwear Manufacturers Special

Quality and Materials

Top knitwear manufacturers in the United States care a lot about quality. They use great materials like superfine merino wool and grade A cashmere. These natural fibers make knitwear strong and comfortable. Their craftsmanship shows in fully fashioned and hand-linked knitwear. This type lasts longer than cut-and-sew knitwear.

They test fabric for strength, tearing, and seams, using ISO 206 rules.

They wash and dry samples to check if colors stay and sizes do not change.

They do flammability tests and use ISO 9001 systems to keep quality high.

Customer reviews and better ways of working help them keep their standards.

Innovation and Technology

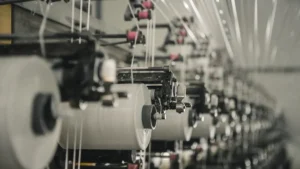

Innovation helps custom knitwear manufacturing get better. Manufacturers buy new machines and use automation to work faster.

The U.S. textile industry spends a lot on new technology and energy-saving tools.

Smart textiles, new synthetic fibers, and recycling are now used in making knitwear.

These changes help make knitwear in a greener way and let brands order custom items.

Customization Options

Custom knitwear manufacturing gives many choices. Customers can pick colors, patterns, and fits using digital tools.

Custom knitwear lets people get products made just for them.

Customers help design their knitwear and can make it match their style.

This way, brands get well-made custom knitwear from good partners.

Sustainability Practices

Sustainability is very important for top knitwear manufacturers.

They use organic fibers, make less waste, and save water and energy.

Certifications like GOTS and ECO PASSPORT by OEKO-TEX show sweaters are safe and eco-friendly.

They use fair labor and buy materials in a way that helps people and the planet.

They are open about where they get materials and work with groups to protect nature.

Top manufacturers use great skills, new ideas, custom knitwear manufacturing, and green practices to make knitwear that fits today’s needs.

Top Knitwear Manufacturer Profiles

Luxury Knit

Luxury Knit is the top knitwear manufacturer in the USA. The company works in a modern factory and uses new knitting machines. They make high-end custom knitwear like sweaters, cardigans, and accessories. The team cares about quality and uses great fibers like merino wool and cashmere. Luxury Knit can make small or big orders, so it is good for both small brands and big stores. The company stands out because it cares about the planet and likes to try new things.

Production and Quality Overview

Manufacturer | Production Volume | Quality Ratings and Attributes |

|---|---|---|

Luxury Knit | Flexible, scalable | High-end quality, luxury craftsmanship, advanced technology, strong sustainability focus |

Luxury Knit makes custom products that always have good quality. This makes it a leader among top knitwear manufacturers in the USA.

Ohio Knitting Mills

Ohio Knitting Mills is in Cleveland, Ohio. The company has made knitwear since the 1920s. They make custom sweaters, scarves, and hats for fashion brands and stores. The company is famous for vintage styles and American-made quality. Ohio Knitting Mills uses old and new knitting machines to make special custom knitwear. The company’s focus on skill and history is great for brands that want real USA-made products.

Straus Knitting Mills

Straus Knitting Mills is in St. Croix Falls, Wisconsin. The company makes custom knitwear for private labels, companies, and events. Straus Knitting Mills makes many things like sweaters, beanies, and blankets. They use new knitting machines to make sure patterns are right and products last long. Straus Knitting Mills can do big or small orders fast.

Royal Apparel

Royal Apparel is in Hauppauge, New York. The company is a top USA knitwear manufacturer that cares about the planet. Royal Apparel makes sweaters, hoodies, and t-shirts with eco-friendly materials. The company lets brands make their own designs and private label products. Royal Apparel is trusted because it uses fair work and makes products in the USA.

Tailored Industry

Tailored Industry is in Brooklyn, New York. The company uses 3D knitting to make custom knitwear with less waste. Tailored Industry helps fashion brands, new companies, and big stores. The company lets brands order custom sweaters and accessories in any amount.

The company watches prices and rules for raw materials.

They plan so they can meet demand now and later.

Business choices are based on revenue and market research.

Tailored Industry uses dashboards to check performance quickly.

The team checks data by talking to people and doing research.

Tailored Industry uses technology and data to make great knitwear. This makes it special among top knitwear manufacturers in the USA.

Unionwear

Unionwear is in Newark, New Jersey. The company is a union shop that makes custom knitwear and accessories. Unionwear makes beanies, scarves, and hats for events, politics, and companies. The company uses fair labor and makes good American products. Unionwear is a top pick for groups that want USA-made knitwear fast and reliably.

Artex Knitting Mills

Artex Knitting Mills is in Westville, New Jersey. The company has made custom knitwear since 1926. Artex Knitting Mills makes beanies, scarves, and headbands for schools, teams, and businesses. The company uses old and new knitting ways to make strong and nice products. Artex Knitting Mills is known for fast work and handling big orders.

Ball of Cotton Inc.

Ball of Cotton Inc. is in Commerce, California. The company makes luxury custom knitwear for fashion brands and shops. Ball of Cotton Inc. makes sweaters, cardigans, and wraps with great yarns. The company lets brands design their own knitwear collections. Ball of Cotton Inc. is special because it pays attention to details and uses American skill.

Evolution Knitwear

Evolution Knitwear is in Los Angeles, California. The company makes custom knitwear for modern fashion brands. Evolution Knitwear uses new knitting machines to make sweaters, dresses, and accessories. The company can do small or big orders and helps with design. Evolution Knitwear is a good partner for brands that want new and high-quality custom knitwear.

America Knits

America Knits is in Swainsboro, Georgia. The company is important in the USA knitwear industry. America Knits makes custom sweaters, shirts, and accessories for big brands and new designers. The company uses new technology like 3D knitting and green materials to make great products. America Knits works in a market where people care about fair work and the planet. The company’s focus on new ideas and custom work shows the high standards of the USA knitwear industry.

The U.S. knitting yarn market has cotton, wool, acrylic, blends, and more.

America Knits makes products for fashion, home, and industry.

The company’s many products and new technology help it stay a top knitwear manufacturer.

America Knits shows how custom sweater manufacturers in the USA can mix tradition, technology, and caring for the planet to help today’s brands.

How to Choose a Knitwear Manufacturer

Assessing Quality

Brands need to check knitwear quality before picking a partner. Good knitwear uses strong fibers and neat stitching. Reliable knitwear manufacturers test for strength, color, and fit. Many offer custom choices like jacquard, embroidery, or intarsia. A good partner shares test results and explains how they check quality. Brands can read reviews and order samples to see real quality.

Comparing Pricing

Custom knitwear prices depend on many things. Brands should look at direct costs like fabric and labor. They should also check indirect costs like overhead and shipping. The table below shows important price facts in the U.S. knitwear industry:

Metric | Value/Statistic | Why It Matters |

|---|---|---|

Industry Sales (2024) | Market size context | |

Average Hourly Pay (Admin) | $19.19 | Labor cost benchmark |

Payroll per Employee | $37,088 | Labor cost benchmark |

Tariff Cost | $80 million | Impacts final pricing |

Operating Expenses Change | -3% (2024) | Cost control indicator |

Custom knitwear with organic fibers or special designs may cost more. These features can make a brand worth more. Brands should compare prices and ask about order size and how flexible production is.

Product Range

A big product range gives brands more options. Top knitwear partners make sweaters, cardigans, hats, and accessories in many colors and sizes. Custom choices help brands make their own styles. Good knitwear manufacturers can do small or big orders. This helps brands grow.

Communication

Clear and quick communication makes strong partnerships. Brands should pick partners who answer fast and use digital tools like real-time tracking. Good communication stops mistakes and keeps projects moving. Reliable knitwear manufacturers use group chats, messages, and shared platforms to keep everyone updated.

Tip: Fast replies and clear updates help brands avoid delays and confusion.

Lead Times

Lead times show how fast a partner can deliver custom knitwear. Brands should ask about total order time, on-time shipping, and how accurate orders are. Nearshoring, or working with U.S. partners, often means faster shipping and fewer problems. Good knitwear manufacturers track order fill rates and use product kitting to deliver faster.

Tips for Working with Knitwear Manufacturers

Building Partnerships

Good partnerships help brands get better knitwear. Companies should try to work closely with their knitwear vendors, not just buy from them. When both sides share ideas, they learn more and do better work. Brands and manufacturers can make products better, save money, and come up with new ideas by working together. Some experts say a supplier keiretsu model is best because everyone helps each other grow.

Brands need to connect their supply chain and focus on what customers want.

A leagile strategy uses both lean and agile ways to manage resources and handle changes.

Good ways to measure success are saving money, quick answers to orders, and selling to other countries.

Working together and coming up with new ideas fast keeps the partnership strong.

Tip: Brands that treat their knitwear manufacturer like a partner, not just a seller, get better results and more custom choices.

Avoiding Pitfalls

Brands can have problems when working with knitwear manufacturers. If people do not talk clearly, mistakes can happen in custom orders. Delays can also happen if the manufacturer is slow to answer or if the design is not clear.

Brands should make clear goals and set timelines for every project.

Checking samples before making everything helps stop big mistakes.

Giving updates and feedback often keeps everyone working together.

Brands should look out for hidden costs or prices that are not clear in deals.

Note: Clear rules and open talks help stop most problems in making knitwear.

Key Questions to Ask

Before picking a knitwear manufacturer, brands should ask some key questions:

What kinds of custom knitwear do you make?

Can you do both small and big custom orders?

How do you check the quality of your knitwear?

How long does it take to finish custom projects?

What do you do if there are changes or problems during production?

What do you do to help the planet in your knitwear process?

Can you give references from other brands?

These questions help brands find a good partner who can make high-quality custom knitwear and meet their needs.

Luxury Knit is the top knitwear company in the United States. They use new technology and check quality very carefully. Other companies like Ohio Knitting Mills and Royal Apparel are also good choices. Each company has something special to offer in knitwear. People should look at the company profiles and follow the tips to pick the best one. They can ask knitwear companies for prices or samples. Learning more helps brands make better choices about knitwear.

FAQ

What types of knitwear can manufacturers in the USA produce?

Manufacturers in the USA make sweaters, cardigans, hats, and scarves. They also make other accessories for brands. Many companies let brands pick custom designs. They use advanced knitting machines to make cool patterns and textures.

How long does it take to complete a custom knitwear order?

How long it takes depends on the company and order size. Most companies finish custom knitwear in 4 to 8 weeks. Some can work faster for small orders or rush jobs.

Are American knitwear manufacturers eco-friendly?

Many American knitwear manufacturers care about the planet. They use eco-friendly materials and safe processes. They often pick organic fibers and recycle waste. They follow strict rules to protect the environment. Certifications like GOTS and OEKO-TEX show they care about sustainability.

Can small brands work with top knitwear manufacturers?

Yes, many top manufacturers take small orders from new brands. They help small businesses by offering low minimums. They also have flexible ways to make products. This lets small brands grow and try new ideas.

What should brands look for when choosing a knitwear manufacturer?

Brands should check quality, prices, and what products are offered. They should ask about how fast orders are done and if the company is eco-friendly. Asking for samples and references helps brands find a good partner.