OEM Knitwear Manufacturing helps you make Massimo Dutti-style cashmere blend pullovers with great quality and care. You get ahead by paying attention to the most important things:

Ask for samples so you can see the quality yourself.

Tell the manufacturer what you want in a clear way.

Pick manufacturers who use new knitting machines and know a lot about luxury yarn.

Choose partners who have made both custom samples and large orders before.

Good OEM partners help you with expert advice, modern machines, and strong quality checks. Working together helps you get the same luxury results every time and quick delivery.

Key Takeaways

Pick OEM partners who have lots of experience and use new machines. They should know about luxury yarn. This helps make high-quality pullovers.

Use materials that are good for the environment. Get cashmere in a fair and honest way. This makes sweaters that look nice and are good for the planet. Customers will trust these sweaters.

Choose knitting ways like seamless or knit-to-wear. These ways make pullovers that feel good and last long. They also help make less waste.

Work with your manufacturer on design, fit, and color. This helps your brand look right and gives customers what they want.

Check quality at every step, from fiber to packaging. Use certifications to show your sweaters are always luxury quality.

Style Elements

Design Features

You want your cashmere blend pullovers to be special. Luxury brands care about more than just softness now. They use materials that are good for the planet. Many European brands pick cashmere that is made in a fair way and use recycled fibers. New knitting methods like flat knitting and 3D seamless knitting are popular. These ways help make sweaters fit better and have fewer seams.

Tip: Adding things by hand, like small embroidery or raised patterns, makes your pullovers unique and strong.

People want sweaters that feel good and can be worn anywhere. They like clothes for both working at home and going out. If you show how you make your sweaters, people will trust your brand more. You can also use digital tools, like letting people try on sweaters online, to help your brand.

Using materials that are good for the earth

Hand-finished touches for a fancy look

Fit and Silhouette

Trends in fit and shape change what people want. Luxury sweaters now focus on comfort and being useful. People like classic crewnecks, big shapes, and dropped shoulders. These styles let your pullovers work for many events.

Soft blends that feel nice to wear

Choices from classic shapes to big, loose ones

Younger people in cities often like big, bold sweaters. Simple, classic shapes are good for people who want a style that lasts. The neck shape matters too. Crewnecks look classic, and V-necks look fancy and are good for layering.

Color Choices

Color is very important in luxury sweaters. Neutral colors like beige, gray, and navy are always liked because they go with many clothes. You can also use colors for each season—light colors for spring and deep, rich colors for winter. Mixing textures and colors or patterns makes your pullovers look new and stylish.

Note: Giving both classic and trendy colors helps you get more customers and keeps your collection exciting.

Material Sourcing

Cashmere Quality

You want your pullovers to feel soft and look nice. They should last a long time. Good cashmere comes from goats with soft undercoats. These goats live in cold places. Inner Mongolia in China is famous for great cashmere. Always check if the fibers are long and fine. Long, fine fibers make yarn that is smooth and strong. This yarn does not pill much and keeps its shape.

Tip: Pick cashmere from ethical sources. Goats should be treated kindly. The fibers should be collected by combing, not hurting the goats.

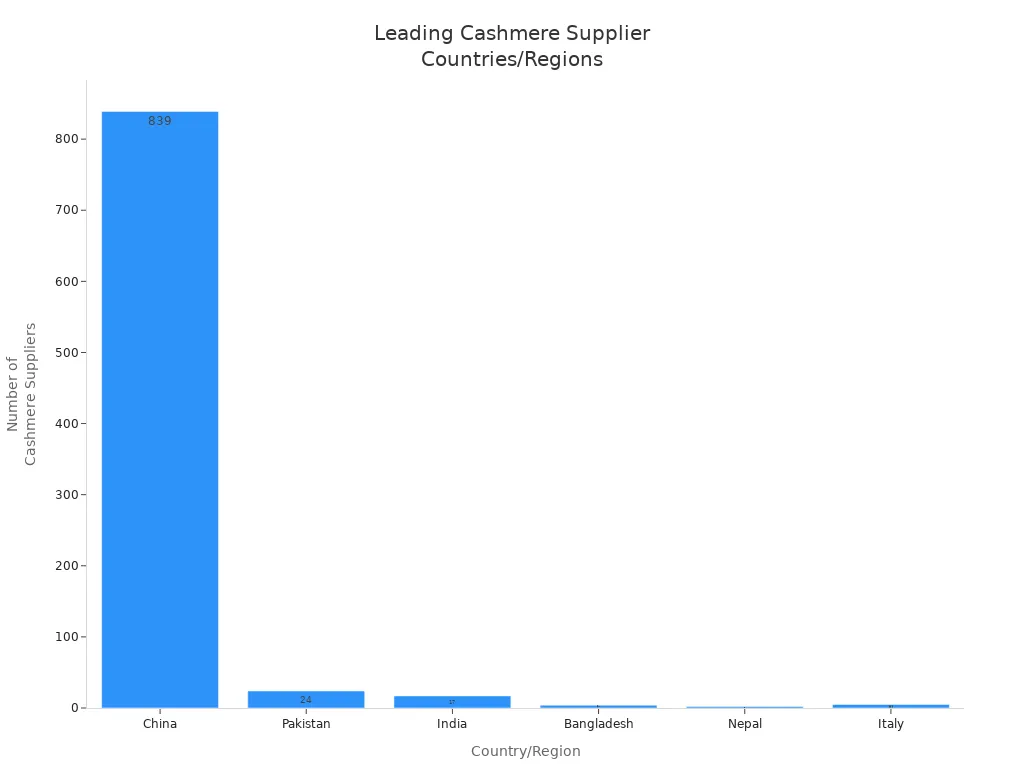

Here is a table that shows which countries have the most cashmere suppliers for OEM Knitwear Manufacturing:

Country/Region | Number of Cashmere Suppliers | Notes |

|---|---|---|

China | China is the top supplier and makes a lot of knitwear for Europe and America | |

Pakistan | 24 | Pakistan is also important |

India | 17 | India is also important |

Bangladesh | 4 | Bangladesh has a few suppliers |

Nepal | 2 | Nepal has a few suppliers |

Italy | 5 | Italy has some suppliers in Europe |

Look for labels like OEKO-TEX, GOTS, or SFA. These show the yarn is safe, organic, and made with care for people and the earth.

Blend Ratios

You can change the blend ratio to get the right feel and price. Pure cashmere is very soft but costs more and can be weak. Many brands mix cashmere with other fibers. This makes sweaters cheaper and stronger. Some common blends are:

70% cashmere / 30% wool: This blend is soft, warm, and lasts longer.

50% cashmere / 50% cotton: This blend is lighter and good for spring.

90% cashmere / 10% silk: This blend is smooth, shiny, and a bit stronger.

Note: The best blend depends on who will wear the pullover and what it is for. Try different blends to see which one is best for comfort, price, and how it wears.

Always check that the blend fits your brand’s promise. Use lab tests to check the fiber content. DNA tests can also show where the cashmere comes from.

Supplier Selection

Picking the right supplier is very important for your pullovers. Look for suppliers who:

Get raw materials from trusted places like Inner Mongolia.

Use good machines for spinning and checking quality.

Follow many steps to make sure the product is good.

Visit herders and pick fibers in a kind way.

Collect cashmere by combing or waiting for it to shed.

Use systems to track each batch from goat to sweater.

Give you certificates and lab results for every order.

Callout: It is important to care about people and the planet. The best suppliers pay workers well and use safe dyes. They help local people and use water and dyes that do not hurt the earth.

Ask about traceability. Good suppliers can show where the cashmere came from and how it was made. They use computers and DNA tests to keep things clear. This helps your customers trust you and helps you follow world rules.

Here are the main things to think about for the environment and ethics:

Use dyes that are safe for the earth and make less pollution.

Make sure workers are safe and paid well.

Help local people and work with herders for a long time.

Use tracking systems so you know where everything comes from.

Pick yarns and dyes that are certified organic.

Make products that last a long time to cut down on waste.

When you work with good suppliers, you help the earth and fair trade. This also helps your brand look better in the luxury market.

OEM Knitwear Manufacturing Process

Knitting Methods

You have to pick the best knitting method for your pullovers. The way you knit changes how the sweater fits and lasts. Tubular knitting makes sweaters without seams. This gives a smooth feel and stops skin irritation. It also makes the pullover stronger because there are fewer weak spots.

Knit-to-wear, or whole garment knitting, uses special machines. These machines make a sweater in one piece. You do not need to sew parts together. This saves time and cuts down on waste. It also helps the sweater fit better and feel more comfy. Flat knitting is still used a lot because it is flexible. You can make panels with different looks and shapes. This is good for custom designs and adding special touches.

Here are the main steps for making cashmere blend pullovers:

Yarn Selection & Preparation: Pick soft, strong yarns and check their color.

Custom Design and Sample Development: Work with designers to make digital patterns and samples.

Knitting & Panel Production: Machines knit panels or whole sweaters using your chosen method.

Linking, Stitching & Assembly: Workers join panels or finish seamless sweaters.

Washing, Ironing & Finishing: Wash, soften, and press the sweaters to make them feel nice.

Quality Control & Inspection: Check each sweater for problems, size, and color.

Packaging & Shipping: Pack and send the finished sweaters to where they need to go.

Tip: Tubular and knit-to-wear methods help you waste less and make sweaters more comfy. These ways also make your work faster and easier.

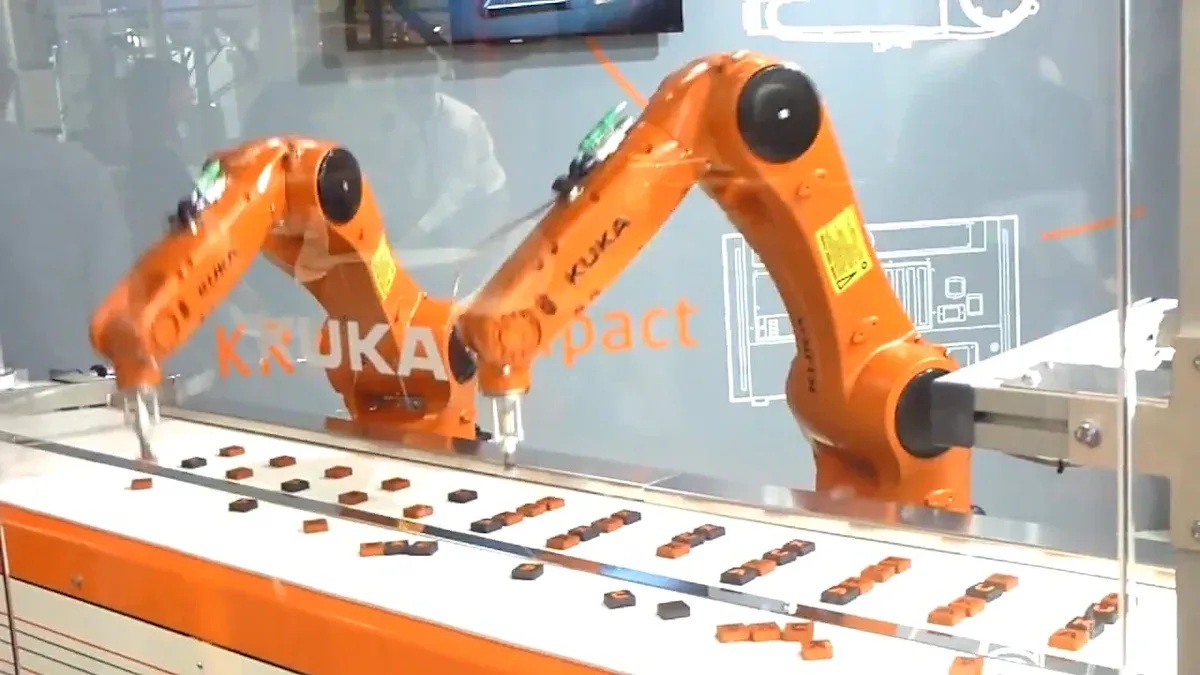

Machinery Selection

You need the right machines to make good sweaters fast. New knitting machines, like computerized flat and 3D ones, help you make cool patterns and seamless sweaters. These machines are more exact and can do more things. You can add special textures, jacquard, embroidery, or intarsia.

Modern factories use CAD/CAM systems to control machines. These systems let you change settings fast and keep every sweater the same. Automated lines help you make both small and big orders with good quality. Some places use ERP systems to track orders and materials. This helps you get sweaters faster and keeps supplies steady.

Note: Pick factories with ISO 9001:2015, BSCI, or bluesign certificates. These show the factory meets high standards for quality and being good to the earth.

Pattern Development

Pattern development shapes how your sweaters look and fit. Digital design tools, like CAD, help you make exact patterns and change them fast. You can see designs, change sizes, and try different yarns before making the sweater. This helps you make fewer mistakes and work faster.

Full-service OEMs do more than just make sweaters. They help with design, samples, and checking quality. You can work with their team to match your brand style. They make samples for you to check, so you know the fit and quality are right.

Here is a table that shows how digital tools and full-service OEMs make things easier:

Service/Process Step | Description |

|---|---|

Uses CAD software to make exact patterns and test ideas. | |

Consultation | Works with brands to match designs to brand style and quality. |

Sample Production | Makes samples to check fit, material, and quality before making more. |

Manufacturing | Uses new knitting machines and skilled workers for good results. |

Quality Control | Checks sweaters at every step to keep quality high. |

Global Logistics | Works with top shippers to deliver sweaters on time everywhere. |

Speed to Market | Fast supply chains and digital tools help you sell sweaters sooner. |

Callout: Digital design and full-service OEMs help you launch new sweaters faster and with less waste. You can test small batches, change things quickly, and make more when needed.

Finishing and Quality Control

Inspection Points

You must check each step to keep your cashmere blend pullovers nice. First, test the fibers to see if they are soft and the right length. This helps make sure the sweaters feel good. Check if the yarn is strong and stretchy so the sweaters last longer. Always look at the color to make sure it matches in every batch. Test if the sweaters pill or shrink after wearing and washing. Look at the carding process to see if the fibers line up well and have no problems. Check how the yarn is spun, like the thickness and twist, to keep things the same. Make sure the washing and blocking steps are done right. Use safe dyes and follow rules like ISO or GOTS. Many brands ask for lab tests or reports to double-check the quality. Doing regular checks and using the same steps every time helps keep all your sweaters the same.

Washing and Pressing

Washing and pressing are important for how your pullovers feel. Washing takes out dirt and makes the fabric softer. After washing, lay the sweater flat to shape it and set its size. This step helps the sweater hang nicely and keeps the stitches even. Pressing makes the pullover look smooth and feel soft and stretchy. These steps help your cashmere blend sweaters feel fancy and look nice.

Packaging

Good packaging keeps your pullovers safe and looking new. Use clean bags to stop dust and damage when shipping. Put tissue paper or inserts inside to help the sweater keep its shape. Many brands pick earth-friendly packaging to help the planet. You can add care labels and brand tags to make it look special. Before sending, check each pullover one last time to make sure it is perfect. OEM Knitwear Manufacturing uses computer systems to track orders and keep quality high from start to finish. This careful work helps you give your customers great sweaters every time.

Cost and Efficiency

Production Scaling

You can make more cashmere blend pullovers and keep them nice. Start by using good farming and grazing methods. Rotational grazing and growing food for goats help you get steady, high-quality materials. Breeding cashmere goats in a smart way makes their fiber better and keeps them healthy. Use machines and technology, like automatic lines and satellite checks, to work faster and more accurately. Certifications and clear labels, like GOTS or RWS, help customers trust your brand. Help herding communities with special programs. Use different supply sources and make extra products to stay strong if things change. Focus on farming that helps the land stay healthy for a long time.

Good grazing and farming

Breeding goats for better fiber

Using machines and satellite checks

Certifications and clear labels

Helping herding communities

Using many supply sources and making extra products

Farming that keeps the land healthy

Studies show that using special tools to check fiber helps keep cashmere quality the same. Top factories use new automatic lines and follow Industry 4.0 rules. This lets you make more sweaters but still keep them soft and strong.

Cost Management

You can save money on luxury cashmere blend sweaters by mixing old skills with new machines. Work with top yarn suppliers to get good prices on nice materials. Use smart ways to knit, like fully fashioned knitting, to waste less and spend less. Making different order sizes helps you plan and control spending. Spend money on things like green energy and cutting waste to save more later.

Work well with yarn suppliers

Knit in smart ways to waste less

Offer different order sizes

Spend on green ideas to save later

The blend you pick changes the cost. Here is a table to compare:

Model | Cashmere Content | Advantages | Cost Implications |

|---|---|---|---|

Base Model | Cheaper, still good quality | Costs less, good for daily wear | |

Advanced Model | 30% | Warmer, feels fancier | Costs more because of extra cashmere |

Pro Model | 35% | Very soft, looks very fancy | Costs the most for material and care |

More cashmere makes sweaters softer and warmer but also costs more to make.

Compliance

You must follow strict rules when making sweaters for fancy European brands. Certifications and doing the right thing are important. Here is a table showing what top makers focus on:

Manufacturer | Key Compliance Requirements and Certifications | Sustainability and Ethical Practices |

|---|---|---|

Madalena Beca Knitwear | Certified supplier; follows rules; over 20 years in business | Makes things in a green way; can change lines for clients |

Infiknit Knitwear | Cares about fair fashion; safe workplaces; treats animals well | Focuses on earth, animals, and worker safety |

Bilyana Knitwear | ISO 9001:2008; Woolmark license; knows natural fibers | Uses natural fibers; special finishing; trusted by top brands |

Pick partners with certificates like ISO 9001 or Woolmark. Make sure they care about safe work, animal care, and green materials. This helps you follow the law and meet what luxury brands want.

You get Massimo Dutti-style sweaters by watching each step in OEM Knitwear Manufacturing. First, pick the best materials you can find. Next, use careful methods to make the sweaters and check the quality often. Talk with your OEM partners a lot so you both want the same things and can help each other.

Always try to get better and use new ideas. This helps you make nicer sweaters, save money, and change plans when needed.

Keep using new machines and work well with your partners. This will help your knitwear stay popular and ahead of others.

FAQ

What makes Massimo Dutti-style cashmere blend pullovers unique?

These pullovers feel soft and look fancy. They use good cashmere mixed with other fibers. The design is classic and lasts a long time.

How do you ensure consistent quality in OEM knitwear manufacturing?

Set clear rules for yarn, color, and fit. Work closely with your OEM partner. Ask for samples and test them in labs. Check each batch for problems.

Which certifications matter most for luxury knitwear?

Look for ISO 9001, OEKO-TEX, GOTS, and Woolmark. These show your sweaters are safe, high quality, and good for the earth.

Can you customize colors and patterns for your brand?

Yes, you can pick from many colors and patterns. OEM factories let you choose special shades or designs for your brand.

How do you reduce waste during production?

Use seamless knitting and digital design tools. These help you use less yarn and make fewer mistakes. Pick earth-friendly packaging to help the planet.