Mohair is a mohair best-seller in knitwear because it is fancy, works well, and can be used in many ways. People who buy mohair like its shiny look and how soft it feels. Mohair is strong and lasts a long time, which is important for knitwear. Many people who buy materials pick a trusted mohair sweater manufacturer to get good quality every time. Mohair becomes more popular as more brands want steady supply and skilled making. In the mohair market, top mohair sweater manufacturer partnerships help new ideas and business grow.

Key Takeaways

Mohair feels soft and looks shiny. It is also very strong. This makes it great for nice sweaters and beanies.

Tests show mohair lasts a long time. It keeps its shape well. Clothes made from mohair still look nice after many wears.

Mohair can be used in many things. People use it for clothes and home items. It is liked by people who care about the planet and fashion.

South Africa makes the most mohair. They give high-quality fibers. These fibers have important eco-friendly certificates.

Pick makers with good quality checks. They should offer OEM/ODM services. Many style choices help you get the best mohair products.

Mohair Best-Seller Qualities

Softness and Sheen

Mohair is popular because it feels soft and looks shiny. Its special fiber shape makes it smooth and bright. Designers and buyers like how it feels and shines. Mohair has longer fibers than other animal fibers. This makes it extra soft. The fiber is round and has fewer scales than wool. This gives it a smooth, shiny look.

Mohair bends easily and bounces back, so it stays soft.

The fibers are even and strong, so quality stays the same.

Mohair can stretch a lot and go back to its shape.

It does not shrink or get tangled, even in water.

Mohair keeps you dry and does not smell bad.

It takes bright colors and still looks shiny, so it is great for fancy clothes.

These things make mohair yarn good for sweaters and beanies. People care about how these items look and feel.

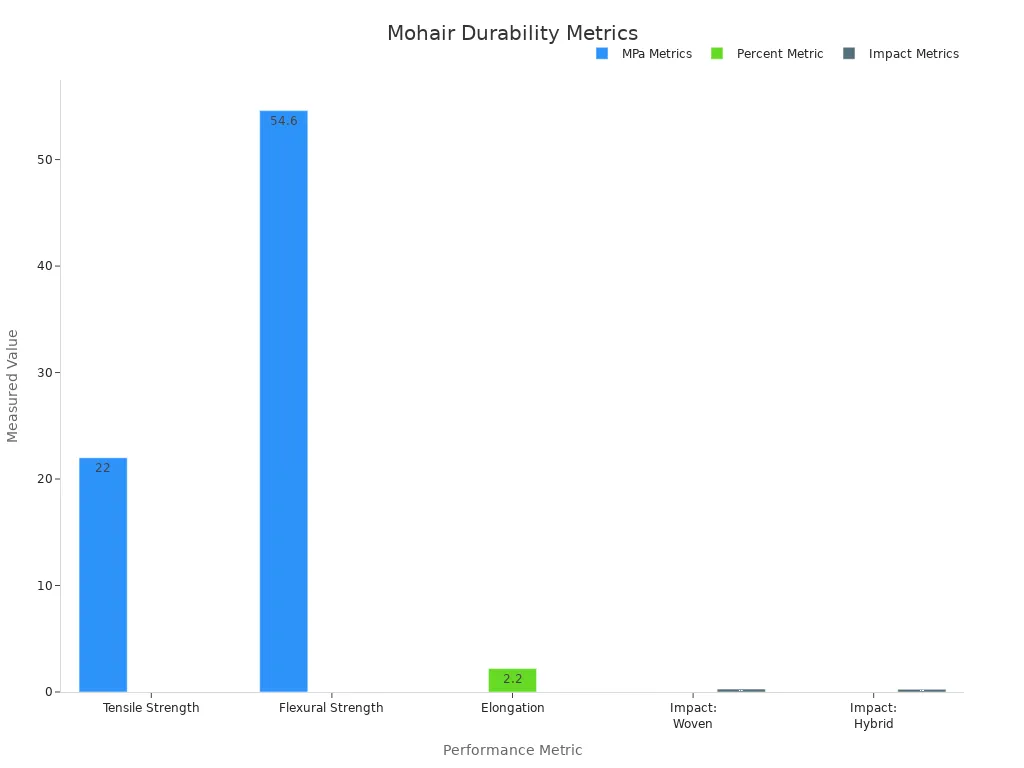

Durability and Performance

Mohair is strong and works well, which makes it a best-seller. Buyers trust mohair because it passes tough tests. Mohair blends with other fibers to get stronger and last longer. Good spinning and few flaws help mohair stay nice and strong.

Property/Test Aspect | Details/Results |

|---|---|

Mohair mixed with other fibers like cotton or wool makes it stronger and softer. | |

Yarn Quality Factors | Good spinning and few flaws make it last longer and look better. |

Abrasion Tests | Special tests check how well mohair stands up to rubbing. |

Abrasion Rating Guidelines | – Under 5,000 rubs: light use |

Additional Durability Factors | Things like seams, pilling, and fabric finish also matter. |

Cleaning & Maintenance | How you clean it changes how long it lasts. |

Test Limitations | Different tests give different results, and many things affect how mohair wears. |

Lab tests show mohair is great for knitwear. Machines test how much rubbing it can take before breaking. Pilling is checked by looking at the fabric after rubbing. Other tests check size, weight, and how tight the knit is. Wear is checked by seeing if the yarn breaks or gets thin.

These tests show mohair is strong and bends well. It is good for clothes that need to last. Mohair keeps sweaters and beanies looking good for a long time.

Versatility in Knitwear

Mohair is used in many ways, which makes it a best-seller. Mohair yarn is light, strong, and feels fancy. It is used for clothes, carpets, and things for the home. This shows mohair can be used for many things. More people want mohair because it is good for the planet and looks nice.

Application Segment | Market Share (2023) | Growth Trend |

|---|---|---|

Clothes | Over 50% | Most common use |

Carpets | Not specified | Important use |

Household Articles | Not specified | Growing fast |

Top designers like mohair for its special feel. People who make crafts also use it for many projects. Mohair mixes with other fibers to work better. This makes it good for both fancy and eco-friendly markets. Asia Pacific is growing fast in using mohair. Mohair is used for sweaters, beanies, and even special knitting projects. It is important for both old and new styles.

Tip: Sellers can use mohair’s many uses to offer more products and meet different needs.

Luxury Mohair Fabric Sourcing

South African Mohair

South Africa is the top country for mohair. It makes more than half of all mohair in the world. Most of this mohair comes from the Eastern Cape. Some also comes from the Western and Northern Cape. South Africa sends mohair to over 70 countries. The mohair market needs this steady supply. Textile buyers trust South African mohair for its good quality and clear records. The table below gives important facts about South Africa’s part in the mohair market:

Category | Data/Details |

|---|---|

Global Mohair Production | |

Number of Countries in Trade | At least 70 countries involved globally |

Top Exporters | South Africa, China, Italy |

Top Importers | India, Peru, United States |

South African Provinces Producing Mohair | Eastern Cape (73%), Western Cape (19%), Northern Cape (6%) |

South African mohair helps make luxury mohair fabric. The mohair industry here has high rules for quality and fair sourcing. Buyers want partners from this area they can trust.

Sustainability and Certifications

Sustainability is very important for the mohair industry’s future. Brands and sellers want wool that is good for the planet and made in fair ways. The Responsible Mohair Standard (RMS) is a top rule for eco-friendly work. Textile Exchange runs this standard to check animal care, land use, and people’s rights. RMS lasts three years and needs regular checks.

The Responsible Mohair Standard (RMS) supports animal care, good land use, and fair treatment.

Getting certified means visits, checking papers, and training.

RMS makes sure mohair is made in a fair and green way, helping people see where it comes from.

Other certifications like ERTS help the environment but are not just for mohair.

Social certifications such as SA8000 and WRAP look at how workers are treated in textile jobs.

Being able to track and trust mohair is important. Textile Exchange works hard to keep checks honest, even when it is hard. Brands that care about the planet want proof that mohair is made right. The mohair industry keeps getting better at being green to meet what buyers want.

Note: Buyers should always look for RMS or other certifications when buying mohair. This helps support fair and green ways of making mohair.

Mohair Manufacturing Process

Yarn Selection

Yarn selection is the first step in making mohair products. Manufacturers pick mohair yarn by looking at its length, how fine it is, and how shiny it looks. Good mohair yarn makes sweaters soft and shiny. Many factories mix mohair with other fibers to make it stronger and feel better. Mohair yarn comes in many grades. Fine yarn is best for fancy sweaters. Thicker yarn is used for strong knitwear. Buyers sometimes want special mohair blends for different sweater styles. This step helps make sure each mohair sweater fits what people want.

Tip: Wholesalers can get mohair yarn samples to check how soft and colorful they are before buying a lot.

Spinning and Blending

Spinning changes raw mohair into smooth yarn. Workers use machines to twist the fibers together. This makes the yarn even and strong for knitwear. Many factories mix mohair with silk, wool, or man-made fibers. These blends can make the yarn shinier or stretch more. Spinning and blending also help control how thick the yarn is. Factories can change the mix to fit each sweater order. Mohair teams check every batch to make sure it is good quality.

Step | Purpose | Result |

|---|---|---|

Spinning | Twist fibers into yarn | Smooth, strong yarn |

Blending | Mix mohair with other fibers | Mohair blends for style and function |

Knitwear Production

Knitwear production uses mohair yarn to make clothes. Machines or skilled people knit the yarn into sweaters, beanies, and other items. Factories offer OEM and ODM services for brands and sellers. OEM means making things from a buyer’s design. ODM means selling ready-made designs that buyers can use as their own. Mohair sweaters come in many types, like cardigans and pullovers. Mohair blends give more choices for color and texture. Each sweater is checked carefully before it is shipped. This makes sure every piece is comfy and looks good.

Note: Custom options help wholesalers sell special mohair sweaters that are different from others.

Mohair Sweater Manufacturer Selection

Picking the right mohair sweater manufacturer is very important. Wholesalers and sourcing experts need to choose carefully. The best partners give strong OEM and ODM services. They also check quality closely and have many styles to pick from. These things help brands give customers the best sweaters.

OEM/ODM Services

A good mohair sweater manufacturer offers both OEM and ODM services. OEM lets buyers use their own designs for sweaters. ODM gives ready-made styles that are quick to sell. The process has steps to make sure sweaters are special and good quality:

Process Stage / Feature | Description |

|---|---|

Design Collaboration | Clients share ideas or patterns to match their brand. |

Material Selection | Manufacturers offer choices from many mohair blends and yarns. |

Sampling Confirmation | Factories send swatches and prototypes, allowing up to three free changes. |

Production & Quality Control | Live video checks and strict standards keep quality high. |

Custom Labels & Packaging | Brands can add their own labels and eco-friendly packaging. |

Technical R&D Facilities | 3D knitting tools help adjust designs quickly and test performance. |

Logistics Assurance | Fast delivery and backup sites reduce trade risks. |

These services help brands make special mohair sweaters. They also help brands keep up with what people want. New tools like 3D knitting make the work faster and better.

Quality Control

Quality control makes sure every mohair sweater is made well. Top manufacturers use numbers to check and improve quality:

First-pass yield shows how many sweaters pass the first check.

Overall Equipment Effectiveness checks how well machines work.

Throughput counts how many sweaters are made in a certain time.

Supplier quality metrics check the mohair yarn before use.

On-time delivery and perfect order rates show if orders are done right.

Manufacturers use sensors, hand checks, and customer comments to get data. They look at this data to find problems and fix them fast. They always try to get better and use new tech like AI to keep mohair and sweaters top quality.

Style Options

A great mohair sweater manufacturer has lots of styles to choose from. Buyers can pick cardigans, beanies, and silk mohair blends. This helps brands meet many customer needs and market wants. Factories use both kid mohair and adult mohair for different feels and strengths. They also offer custom colors, patterns, and finishes so brands can be unique.

Tip: Brands should touch and look at samples to check softness, shine, and stretch. This helps make sure the mohair is good and the sweater is just right for their collection.

Choosing a manufacturer with strong OEM/ODM services, good quality checks, and many styles means sweaters are always good and there are lots of choices. This helps brands do well in the busy mohair market.

Mohair is special in knitwear because it is always good quality and helps the planet. Buyers like to work with manufacturers who have strong OEM and ODM services. They also want partners who always make high-quality products. Sourcing experts should pick suppliers who care about the environment and have many products to choose from. Buyers can add more styles by looking at new mohair designs and checking if suppliers have the right certifications.

FAQ

What makes a mohair cardigan sweater popular among wholesalers?

A mohair cardigan sweater feels soft and looks shiny. Wholesalers like it because it stays strong for a long time. It still looks new after many wears. Brands enjoy its special texture and many color choices.

How do manufacturers ensure quality in mohair beanie production?

Manufacturers check quality at every step. They test the yarn for strength, color, and softness. Workers look at each beanie before it is sent out. This helps brands get only the best products.

Can buyers request custom designs for silk mohair knitwear?

Yes, buyers can ask for custom designs. Manufacturers give OEM and ODM services. Clients can share their ideas or pick ready-made styles. This helps brands be different in the market.

Why do sourcing professionals prefer knitting for olive mohair?

Knitting with olive mohair uses fine yarns for soft, light pieces. Sourcing professionals like its gentle feel and pretty finish. It fits both old and new fashion styles.

What certifications should buyers look for when sourcing mohair products?

Buyers should look for certifications like the Responsible Mohair Standard (RMS). This shows the mohair is made in a fair and kind way. It also means the product meets high social and environmental rules.