If you own a knitwear business, you might know “minimum order quantity” or MOQ. It means the smallest number of items you must buy at once. Why is it important? MOQ affects how much you spend and price your products. For example, making 300 knitwear pieces in the U.S. might cost $25 each. But getting the same amount from China could cost only $10 each. This shows how MOQ impacts your money, supplier options, and deals with manufacturers.

Key Takeaways

Minimum Order Quantity (MOQ) is the smallest number of products you must buy from a supplier. Knowing MOQ helps you control costs and set fair prices.

High MOQs can be hard on your budget, especially for small businesses. Find suppliers with lower MOQs or ask for better deals to save money.

Balancing MOQ with what you need to stock is important. Plan carefully and predict demand to avoid buying too much or wasting money.

Work with other businesses to place group orders. Sharing orders can help you meet MOQ rules and spend less.

Building good relationships with suppliers can give you more flexible MOQ choices. Explain your needs clearly to get better offers.

What Is Minimum Order Quantity (MOQ)?

Definition and Examples in Knitwear Production

Minimum Order Quantity, or MOQ, is the smallest number of items you must buy from a supplier. It’s common in manufacturing, including knitwear, to cover production costs and stay profitable. As a knitwear business owner, knowing about MOQ is important. It affects your pricing, stock, and ability to meet customer needs.

MOQs in knitwear can differ based on material, design, and complexity. For example:

A supplier might ask for 200 pieces for a simple cotton sweater.

A detailed cashmere cardigan might need 500 pieces due to higher costs.

Some suppliers change MOQs for different colors or sizes, making planning harder.

In the past, high MOQs were typical, especially for basic, cheap items. But now, smaller factories offer lower MOQs to attract small businesses and niche markets. This change lets you order fewer items without committing to large amounts.

My knitwear company faces MOQ challenges with small retailers. We group yarn orders for multiple clients into one batch. For instance, we buy 100kg of cashmere and split it among three clients. Discounts are given to clients using shared yarn. This helps us lower costs.”

This example shows how businesses can handle MOQs creatively. By sharing resources or negotiating deals, you can make MOQs work better for your needs.

Why Do Manufacturers Have MOQ?

Why do manufacturers set MOQs? It’s about keeping production efficient and profitable. Here’s why:

Covering Production Costs: Making products costs money, like setting up machines and buying materials. MOQs spread these costs across more items, lowering the cost per piece.

Maintaining Profit Margins: Small orders can lead to losses. MOQs ensure suppliers don’t lose money on production.

Streamlining Operations: Making many items at once is faster than stopping for small batches.

Managing Inventory: Suppliers buy materials in bulk for better prices. MOQs help them use these materials without wasting them.

For knitwear, MOQs matter because of the materials used. Yarn is often bought in large amounts. If your order is too small, leftover yarn may go to waste, raising costs.

Knowing why MOQs exist helps you plan smarter orders. You can even negotiate better terms with suppliers. Whether ordering in bulk or creating custom designs, understanding MOQs helps you make better business choices.

Importance of MOQ for Knitwear Businesses

Impact on Production Costs and Pricing

MOQ affects how much you spend and price items. Meeting MOQ helps manufacturers work more efficiently. This lowers the cost per item, keeping profits steady. For example, making 500 sweaters at once costs less than making 50. Why? Setup costs, like machine prep, are shared across more items.

But high MOQ can use up your money quickly. You may need to buy in bulk, which can strain your budget. If you’re new or testing designs, this feels risky. On the bright side, some suppliers give discounts for big orders. Planning wisely can save you money over time.

Role in Supplier Relationships

Suppliers like working with businesses that meet MOQ. It shows you’re serious and dependable. Meeting MOQ builds trust, leading to better deals later.

What if you can’t meet MOQ? Try negotiating. Many suppliers adjust MOQ for small businesses or custom orders. For example, you could ask for a smaller MOQ but pay more per item. This way, both sides benefit.

Effect on Inventory Management and Cash Flow

MOQ affects how you handle stock and money. Bulk orders need storage space and tie up cash. This is tough if your knitwear is seasonal or trendy and might not sell fast.

Here’s a comparison:

Aspect | Seller Impact | Buyer Impact |

|---|---|---|

Inventory | Stores large amounts, raising costs. | Must sell or use MOQ quickly. |

Cost Management | Higher MOQ increases storage expenses. | May need suppliers with lower MOQ or extra storage. |

Financial Impact | Money stuck in unsold stock. | Must balance storage costs and bulk savings. |

Product Viability | Hard to manage if styles change quickly. | Must check if items will stay in demand. |

Balancing MOQ with your needs is important. If storage or cash flow is tight, find suppliers with low MOQ. You can also team up with others to share orders. This keeps you flexible while meeting your goals.

Factors Influencing Minimum Order Quantity

Raw Material Availability and Purchase Requirements

Raw materials greatly affect MOQ for knitwear. Suppliers often buy yarn in bulk to save money. This means they need you to order enough items to use these materials efficiently. For example, if a supplier buys 500 kilograms of wool, they’ll set an MOQ to avoid wasting it.

Here’s how raw materials impact MOQ:

Aspect | Explanation |

|---|---|

Cost Efficiency | Making more items lowers costs by using bulk materials. |

Profitability | MOQ ensures suppliers sell enough to avoid losing money. |

Inventory Control | High MOQ helps manage stock and keeps quality steady. |

Order In Bulk | Bulk buying gives discounts and lowers financial risks. |

Small businesses might find this hard to manage. You can negotiate with suppliers or share material costs with others. This helps you meet MOQ without spending too much money.

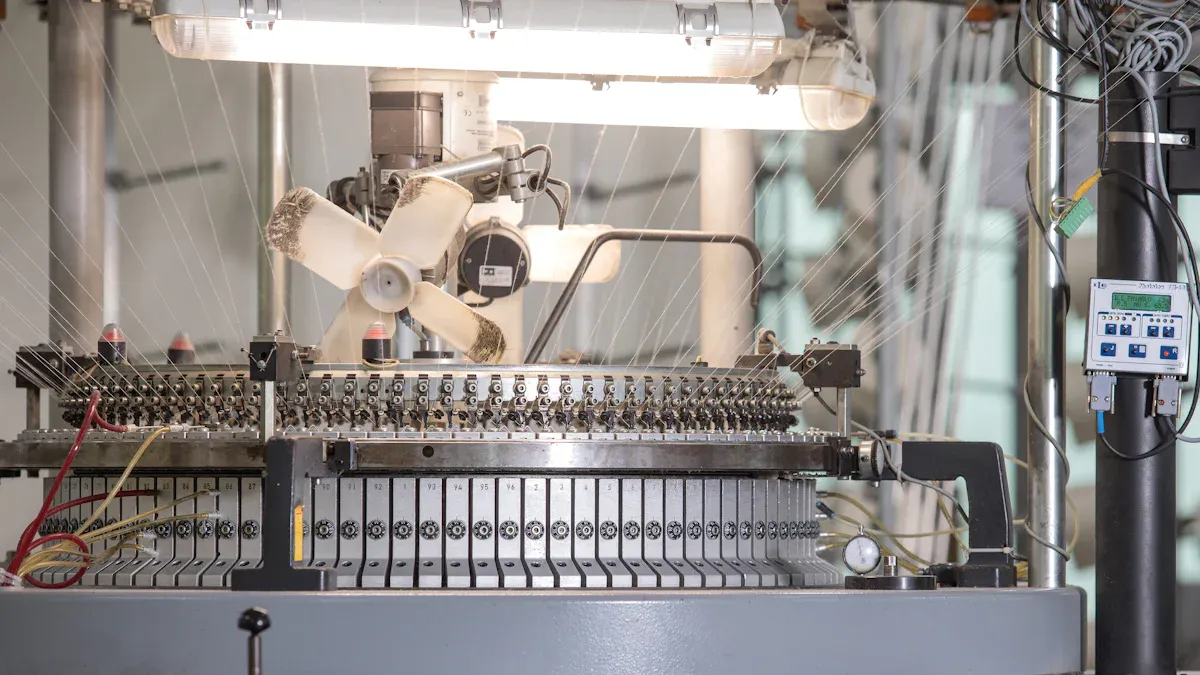

Production Processes and Setup Costs

Every production run has setup costs, like preparing machines and training workers. To cover these costs, suppliers often require higher MOQ. For example, a T-shirt maker might need you to order 500 shirts to make setup costs worth it.

Here’s why MOQ depends on production:

Higher setup costs mean higher MOQ to cover expenses.

Making more items spreads costs, lowering the price per piece.

Bigger orders improve efficiency and reduce overall costs.

If your knitwear has complex designs, expect higher MOQ. Simpler designs may allow smaller orders. Always ask suppliers about setup costs and how they affect MOQ.

Supplier Capacity and Efficiency

Suppliers set MOQ based on their ability to produce efficiently. Factories with advanced machines handle bigger orders faster, leading to higher MOQ. Smaller suppliers may offer lower MOQ, but their prices per item are often higher.

Global issues can also raise MOQ. For example, during trade problems, suppliers may increase MOQ to stay profitable. Knowing your supplier’s limits helps you plan and negotiate better deals.

Tip: Build trust with your suppliers. They may lower MOQ or offer better terms if they value your business.

Customization and Design Complexity

Customization and how complex a design is can affect MOQ. If you want special designs or detailed patterns, suppliers may ask for bigger orders. Why? Complicated designs take more time and effort to prepare.

For example, knitting machines need changes for fancy patterns. This setup takes longer than for simple designs. Suppliers ask for larger orders to make up for this extra work. But printing methods can handle smaller MOQs, even for tricky designs. If your knitwear has embroidery or special stitching, expect higher MOQs because of the extra labor.

Here’s how design complexity affects MOQ:

Setup Time: Fancy designs need more time to prepare machines.

Material Usage: Special designs may need unique yarns or colors bought in bulk.

Production Efficiency: Bigger orders help cover the time spent on setup.

Custom designs also change pricing. Small orders with detailed designs often cost more per item. Bulk orders may get discounts, but small orders can be pricey. Balancing your design ideas with MOQ rules is important.

Tip: If you’re a small business, try simpler designs or negotiate flexible MOQ terms. Some suppliers lower MOQ for custom orders if you pay a bit more per item. This helps you get your designs without ordering too much.

Custom designs are fun but can be tricky. Knowing how design complexity impacts MOQ helps you plan better and save money.

Pros and Cons of Minimum Order Quantity

Benefits for Suppliers (Cost Efficiency, Streamlined Production)

MOQ helps suppliers work faster and save money. Bulk orders let them run machines without stopping for small batches. This saves time and lowers costs. It also boosts profits for the supplier.

Suppliers can plan better with MOQ. They know how much material to buy and avoid making too much. For example, buying yarn in bulk means less waste and fewer storage problems.

Tip: Meeting MOQ helps suppliers and gets you better prices. Lower costs mean higher profits for your business.

Challenges for Buyers (Upfront Costs, Storage Needs)

MOQ can be hard for buyers. You need a lot of money upfront to meet high MOQ. Small businesses may struggle with cash flow because of this.

Storage is another problem. Bulk orders need space, and unsold items cost money. Seasonal or trendy knitwear can lose value if it doesn’t sell fast.

Note: If high MOQ is tough, find suppliers with lower MOQ. This helps you save money and avoid storage issues.

Balancing MOQ for Mutual Benefit

Balancing MOQ helps both suppliers and buyers. Suppliers stay profitable and avoid waste. Buyers get good deals without buying too much. Planning and negotiating MOQ can make things easier.

Here’s how it works:

Suppliers use materials wisely and avoid making extra items.

Buyers save money by planning bulk orders carefully.

Both sides build strong, lasting partnerships.

Tip: Work with other businesses to share orders. This lets you meet MOQ without spending too much.

Balancing MOQ is more than numbers. It’s a smart way to grow your knitwear business and keep good supplier relationships.

How to Manage and Negotiate MOQ Effectively

Finding Low MOQ Manufacturers

Finding suppliers with low MOQ can be tricky but possible. Many small factories now help businesses that need fewer items. They understand small businesses may test designs or start new projects.

How can you find these suppliers? Use websites like Alibaba or ThomasNet. These sites let you search for suppliers with low MOQ. Join online groups or forums where knitwear owners share tips. Trade shows are also helpful for meeting suppliers and learning their MOQ rules.

When contacting suppliers, ask clear questions about MOQ. For example, “What’s your MOQ for knitwear?” or “Do you offer flexible MOQ?” This helps you know if their terms fit your needs.

Tip: Look for suppliers who make small batches. Their prices may be higher per item, but lower MOQ saves money and space.

Negotiating MOQ with Suppliers

Talking about MOQ with suppliers can feel hard, but it gets easier. Suppliers set MOQ to cover costs, but many will adjust if asked nicely.

Explain your situation clearly. Tell them why you need a smaller MOQ. If you’re testing products or are a small business, they may agree. Offer to pay more per item for fewer pieces. This helps suppliers keep profits while you avoid buying too much.

Another idea is to ask for a trial order. Request a small batch first instead of the full MOQ. If it works well, you can order more later. Suppliers like loyal customers, so showing long-term interest helps.

Note: Be polite and professional when negotiating. Good relationships with suppliers lead to better deals and flexibility.

Leveraging Group Orders or Partnerships

If MOQ feels too high, team up with other businesses. Group orders let you share costs and meet MOQ together. This works well for businesses using similar materials.

For example, three knitwear brands needing the same yarn can combine orders. The supplier gets a big order, and each brand pays for their part. This helps meet MOQ and builds industry connections.

You can also partner with stores or wholesalers. Talk about their stock needs and see if they’ll order more. This lets you meet MOQ without keeping extra items yourself.

Tip: Clear communication is important in partnerships. Agree on payment, delivery, and how the order will be split.

Optimizing Inventory to Meet MOQ Requirements

Managing inventory well helps meet minimum order quantity without wasting money or space. Keeping stock levels balanced saves cash, lowers storage costs, and ensures you can meet customer needs. Here are some simple ways to match your inventory with MOQ rules.

Use the ABC Model to Organize Stock

Not all products are equally important. Some make more money, while others don’t. The ABC model helps you focus on key items. Here’s how it works:

Category | Description | Importance |

|---|---|---|

A | 20% of items making 80% of revenue. Needs close tracking. | Most important for stock management. |

B | 30% of items making 15% of revenue. Needs moderate tracking. | Medium importance, may move to other categories. |

C | 50% of items making 5% of revenue. Needs less tracking. | Least important, steady but low earnings. |

Sort your knitwear into A, B, and C groups. Spend more time managing Category A items since they earn the most money. This way, you meet MOQ for top products without wasting money on less important stock.

Predict Demand to Avoid Overstocking

Guessing future sales is key to handling MOQ. Look at past sales, seasons, and customer likes to decide how much to order. For example, if wool sweaters sell more in winter, plan your MOQ orders for that season. This stops you from ordering too much and keeps your stock useful.

Tip: Use software to track sales and predict demand. It saves time and helps you make smarter choices.

Work with Suppliers for Flexible MOQ

If a supplier’s MOQ feels too high, try negotiating. Many suppliers adjust MOQ for small businesses or special orders. You can ask to split orders into smaller batches or change MOQ for custom designs. Building good relationships with suppliers often leads to better deals.

Plan Bulk Orders Wisely

Big orders can be scary but often come with discounts. Plan carefully to make the most of bulk buying. Combine orders for different products or team up with other businesses to share costs. This helps you meet MOQ without filling your storage with extra items.

Note: Always check how bulk orders affect storage and money. Discounts won’t help if you can’t store or sell the extra stock.

Review and Adjust Often

Managing inventory isn’t a one-time job. Check your stock, sales, and supplier terms regularly to meet MOQ smartly. If some items don’t sell well, change your plan. Order less of slow-selling items or try new designs that customers might like.

By staying flexible and active, you can turn MOQ challenges into chances to grow. Good inventory management helps meet supplier rules and improves your business overall.

Knowing minimum order quantity for knitwear is key to success. It affects your spending, supplier deals, and stock control. Learning to handle and discuss MOQ well can save money and prevent extra inventory.

Look for suppliers with flexible MOQ for knitwear or those who make small batches. Use tools to predict sales and plan your knitwear bulk order MOQ smartly. Always try to negotiate MOQ with suppliers—many will adjust for custom designs.

MOQ isn’t just a problem. It’s a way to get knitwear wholesale pricing, build trust with suppliers, and grow your business wisely. With smart planning, MOQ can benefit you.

FAQ

1. What is the best MOQ for knitwear?

The best MOQ depends on your product and supplier. Simple designs may need 100-200 pieces. Custom or detailed designs often need 500 pieces or more. Talk to suppliers to find what works for both sides.

2. Can I ask suppliers to lower MOQ?

Yes, you can! Many suppliers adjust MOQ for small businesses or custom orders. Share your needs and offer to pay a bit more per item. A strong relationship with your supplier can lead to better terms.

Tip: Request a small trial order to check their flexibility.

3. How does MOQ impact knitwear prices?

Higher MOQ means lower costs per item. Bulk orders save suppliers money, so they charge you less. Smaller MOQ costs more because setup and materials are pricier for fewer items.

4. Why is MOQ helpful for buyers?

MOQ gives you steady quality and better prices. It also helps you manage stock well. Bulk buying often includes discounts, making it easier to control costs and meet customer needs.

5. How do I handle high MOQ for knitwear?

Work with other businesses to share orders or choose simpler designs with lower MOQ. Plan your orders based on demand to avoid extra stock. Negotiate with suppliers for flexible MOQ options.

Note: Use tools to track inventory and plan smarter orders.