Marks & Spencer knitwear manufacturer partners with leading factories in 2025. The Marks & Spencer knitwear manufacturer sources products from a variety of countries, including Bangladesh, China, Cambodia, India, Pakistan, Sri Lanka, Türkiye, and Vietnam. Recently, the Marks & Spencer knitwear manufacturer has added new suppliers in Vietnam and Cambodia, while some partnerships in China and Pakistan have ended. These shifts impact quality, pricing, and compliance with fairness standards.

Main supplier countries for Marks & Spencer knitwear manufacturer:

Bangladesh

China

Cambodia

India

Pakistan

Sri Lanka

Türkiye

Vietnam

Key Takeaways

Marks & Spencer gets knitwear from many countries. Vietnam, India, Sri Lanka, and Turkey are main suppliers in 2025. The company found new suppliers in Vietnam and Cambodia. This helps improve quality and keep prices fair. Marks & Spencer stopped working with some factories in China and Pakistan. They did this to keep high quality and good standards. The brand uses sustainable materials. They follow strict rules for factories. These rules make sure workers get fair pay and work safely. Customers can trust Marks & Spencer knitwear. It has good quality, fair prices, and responsible sourcing. Look for the “Responsibly Sourced” label.

Marks & Spencer Knitwear Manufacturer List

Key Supplier Countries

Marks & Spencer knitwear manufacturer works with factories in many countries. These places help make the brand’s knitwear. The table below lists the main supplier countries and their export value for 2025:

Country | Export Value in 2025 (USD million) |

|---|---|

Vietnam | |

India | N/A |

Sri Lanka | N/A |

Turkey | N/A |

Brazil | N/A |

Vietnam is a top source for Marks & Spencer knitwear manufacturer in 2025. India, Sri Lanka, Turkey, and Brazil are also important, but their export values are not known right now. Marks & Spencer knitwear manufacturer also gets products from Bangladesh, China, Cambodia, and Pakistan. These countries are part of the brand’s worldwide supply chain.

Note: Marks & Spencer knitwear manufacturer keeps changing its supplier list to keep quality and fairness high. The company’s focus on Vietnam shows it wants production that is reliable and not too expensive.

Notable Manufacturers

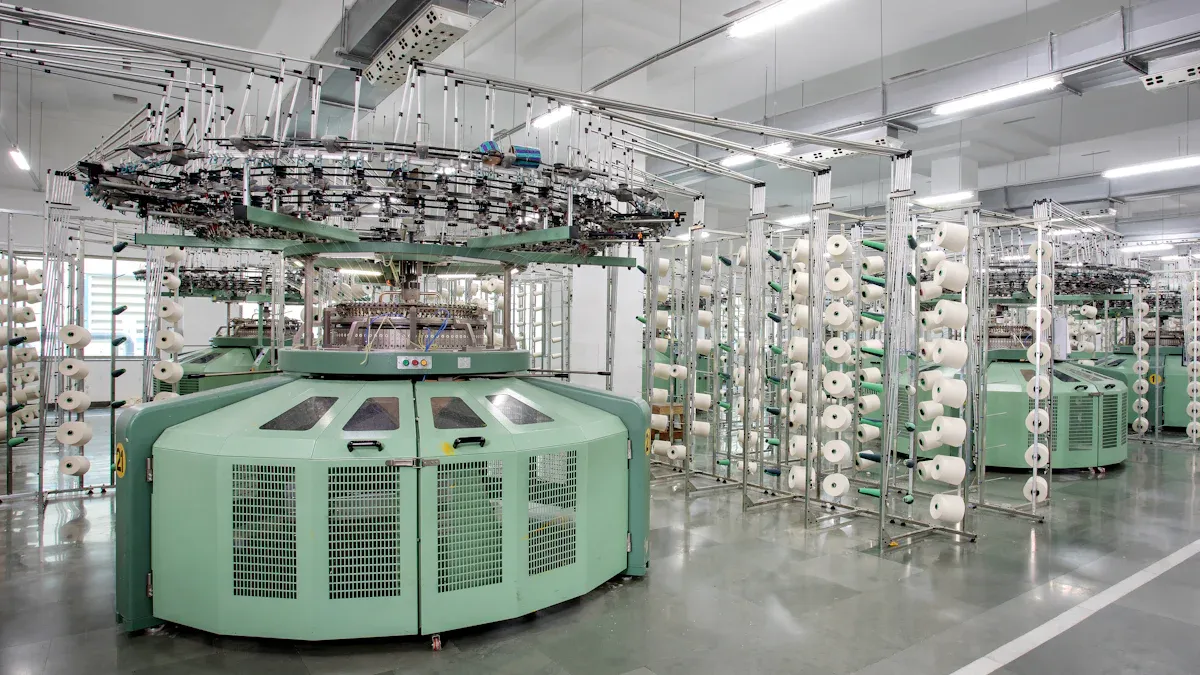

Marks & Spencer knitwear manufacturer uses many trusted factories. Most factory names are kept private, but some are known for good work and following rules. In Vietnam, big textile factories make sweaters, cardigans, and other knitwear for Marks & Spencer knitwear manufacturer. India and Sri Lanka also have well-known factories with skilled workers.

Marks & Spencer knitwear manufacturer is part of the Better Cotton Traceability initiative. This program started in November 2023 to make the supply chain clearer. The initiative has over 400 ginners and 700 suppliers and manufacturers. Marks & Spencer knitwear manufacturer and other brands have bought more than 90,000kg of Physical Better Cotton through this program. This shows the company cares about responsible sourcing and being open.

Marks & Spencer is part of the Better Cotton Traceability initiative.

The initiative tries to make the supply chain clearer.

Over 400 ginners and 700 suppliers and manufacturers are involved.

More than 90,000kg of Physical Better Cotton has been bought by retailers and brands, including Marks & Spencer.

Marks & Spencer’s work shows it cares about being open in the knitwear supply chain.

Marks & Spencer knitwear manufacturer keeps checking and updating its supplier list. The company chooses factories that have high standards for quality, fairness, and caring for the environment.

Supplier Changes

New Partnerships

Marks & Spencer knitwear manufacturer grew its group of suppliers in 2025. The company started working with new factories in Vietnam and Cambodia. These new partners help the brand make more knitwear for customers. Many of these factories have new machines and do careful quality checks. Marks & Spencer knitwear manufacturer picked these suppliers because they are dependable and have good prices.

Factories in Vietnam are now more important in the supply chain. Many of these places treat workers fairly and follow rules. Cambodian suppliers add new ideas and styles to the collection. The company likes these new partners because they can fill big orders fast. This helps Marks & Spencer knitwear manufacturer keep products good and not too expensive.

Note: New partners can give more choices and faster delivery.

Ended Contracts

In 2025, Marks & Spencer knitwear manufacturer stopped working with some suppliers in China and Pakistan. The company made this choice after checking how the suppliers were doing. Some factories did not reach the new quality rules. Others did not follow the company’s new rules for fair sourcing.

Stopping these contracts helps the brand stay trusted. Marks & Spencer knitwear manufacturer wants to work with suppliers who share its values. The company now checks factories more often to make sure they follow all rules. This way, the supply chain stays strong and honest.

Reasons for supplier changes:

Better product quality

Lower costs to make products

Higher standards for fairness

These changes show that Marks & Spencer knitwear manufacturer always tries to get better. The company changes fast to meet what the market and customers want.

Impact on Quality and Pricing

Product Quality

Marks & Spencer wants to give customers great knitwear in 2025. The company picks factories with new machines and skilled workers. These suppliers check quality at every step. This helps make knitwear feel better and last longer. Customers notice that the clothes fit well and are strong.

New suppliers in Vietnam and Cambodia use new ways and tools. These factories help Marks & Spencer keep high standards. The company works with suppliers to make sure products are always good. They check factories often and talk about how to improve.

Customers say the new knitwear is soft and lasts a long time. Marks & Spencer’s focus on quality makes people trust the brand.

The company does not stop checking after the factory. Marks & Spencer tests knitwear in real life before selling it. This makes sure the clothes stay nice after many washes.

Pricing Effects

Marks & Spencer pays more for supplies and worker pay in 2025. Even with these higher costs, the company tries not to raise prices much. The CEO, Stuart Machin, says they want to keep prices steady for knitwear. He says the company wants to give good value and style without making things too costly.

Marks & Spencer works with suppliers who have good prices. The company also uses smart ways to make products and save money. These steps help keep prices from going up a lot.

Main points about prices in 2025:

Knitwear prices do not go up much.

The company wants to keep things affordable.

Good prices help the brand get more customers.

Marks & Spencer’s plan lets more people buy nice knitwear at fair prices. The brand’s work to balance quality and cost makes shoppers trust them.

Ethical Sourcing

Sustainability Initiatives

Marks & Spencer cares a lot about being green in its knitwear supply chain. The company spends money on programs that help nature and local people. Marks & Spencer uses organic and recycled fibers in many knitwear items. These materials help make less trash and are better for the earth.

The company joins the Better Cotton Traceability initiative. This program follows cotton from the farm to the finished product. It makes sure the cotton comes from good places. Marks & Spencer also works with suppliers who use less water and energy. Many factories use solar panels and recycle water to stop pollution.

🌱 Tip: Customers can find the “Responsibly Sourced” label on Marks & Spencer knitwear. This label means the product meets tough environmental rules.

Marks & Spencer has clear goals to cut carbon emissions. The company wants to reach net zero emissions by 2040. It also helps projects that bring back forests and protect animal homes. These steps show the company really wants a cleaner future.

Factory Standards

Marks & Spencer makes all factories follow strict rules. The company checks every factory before working with them. Auditors visit factories to look at working conditions and safety. They check for fair pay, safe tools, and clean places to work.

Factories must follow the Marks & Spencer Global Sourcing Principles. These rules talk about worker rights, health, and safety. The company does not allow child labor or forced labor anywhere. Marks & Spencer also teaches factory managers about doing the right thing.

Key factory standards include:

Fair pay for all workers

Safe and healthy places to work

No unfair treatment or bullying

Regular checks and visits

Marks & Spencer shares a list of approved factories every year. This list lets customers know where their clothes are made. The company thinks being open builds trust and helps ethical sourcing.

Marks & Spencer knitwear manufacturer uses trusted factories in Vietnam, India, Sri Lanka, and Turkey. The company also works with other important countries. They started working with new partners in Vietnam and Cambodia. Some contracts in China and Pakistan have ended. These changes help make products better and keep prices the same. The company still cares a lot about fair sourcing and factory rules. People should look out for more updates as the supplier list changes.

FAQ

Where does Marks & Spencer source most of its knitwear in 2025?

Marks & Spencer gets most knitwear from Vietnam, India, Sri Lanka, and Turkey. The company also works with factories in Bangladesh and Cambodia. Some other countries help make knitwear too.

How does Marks & Spencer ensure factory standards?

Marks & Spencer checks factories often and has strict rules. They look for fair pay and safe places to work. No child labor is allowed. Factories must follow the Marks & Spencer Global Sourcing Principles.

Are all Marks & Spencer knitwear products made with sustainable materials?

Many knitwear items use organic or recycled fibers. Marks & Spencer joins programs like the Better Cotton Traceability initiative. These programs help the company buy cotton in a responsible way.

Why did Marks & Spencer end contracts with some suppliers?

Marks & Spencer stopped working with some suppliers in China and Pakistan. The company wanted better quality and higher ethical standards. This helps make sure products are good and fair.

How can customers identify responsibly sourced knitwear?

Customers should look for the “Responsibly Sourced” label on knitwear. This label means the product meets tough rules for the environment and ethics.