When you look for a knit polo shirt manufacturer, you often choose between OEM and ODM models. OEM lets your brand control every detail of your knit polo shirt, so established brands or private label fashion companies often pick this route. ODM offers ready-made designs, which helps startups or boutique brands launch collections faster. You should think about what matters most for your brand: design freedom, cost, speed to market, and order size. Each brand finds its best fit by matching needs with the right model.

Key Takeaways

OEM lets your brand pick the design, fabric, and details. This makes your knit polo shirts special. It also helps protect your brand’s look.

ODM gives you ready-made designs to use. This helps new or small brands start selling shirts faster. It also costs less money. But you will share these designs with other brands.

If you choose OEM, it will cost more money. You will wait longer for your shirts. You must also order more shirts at once. ODM is faster, cheaper, and lets you order fewer shirts.

Both OEM and ODM let you change some things. OEM lets you change everything about the shirt. ODM only lets you change colors, logos, and packaging.

Make a checklist to help you decide. Ask questions about your budget, how fast you need shirts, how many you want, and how much control you want over your brand. This will help you pick the best way to make your shirts.

Knit Polo Shirt: OEM vs ODM

OEM Overview

If you pick OEM, you control your knit polo shirt. You make your own design and pick the fabric. You decide on every small detail. OEM lets you make a shirt that matches your brand. You work with the manufacturer to make your ideas real. First, you draw sketches and make patterns. Then, you choose fabric like 100% cotton or a cotton blend. The manufacturer cuts and sews the fabric. They add your logo or print. They check the shirts for quality before packing and shipping.

OEM gives you full ownership of your design. You can protect your brand and keep your shirts special. This is good if you want your brand to stand out. You need time and money for research and design. OEM takes longer, from one to six months. You may have to order more shirts at once. But you get to choose everything about your shirt.

Tip: OEM is good for brands with a strong design team. You can make a look that is only yours.

ODM Overview

ODM is a faster way to make your knit polo shirt. The manufacturer already has designs and fabric choices. You pick a style from their catalog. You add your logo and change things like color or packaging. ODM skips the long design steps and gets your shirt to market fast.

Many ODM manufacturers use special knitting machines. They make fabrics like polyester spandex pique knit. This fabric is strong and lets air through. It can also keep you dry or fight germs. You do not need to find fabric or make new patterns. The manufacturer does most of the work. You save time and money.

ODM is good for new brands or small shops. You can order fewer shirts to test the market. You do not own the design. Other brands may sell the same shirt. But you pay less, get shirts faster, and use the manufacturer’s skills.

ODM clothing production advantages:

Fast product development (1 to 4 weeks)

Lower minimum order sizes

Use proven styles and fabrics

Save money with ready-made designs

Key Differences

You should compare OEM and ODM to see what fits your brand. Here is a table that shows the main differences for making knit polo shirts:

Operational Factor | OEM Manufacturing | ODM Manufacturing |

|---|---|---|

Product Design Responsibility | You give all design details | Manufacturer has designs ready |

Intellectual Property Ownership | You own your design | Supplier owns the design |

Customization Flexibility | You can change anything | Only small changes allowed |

Product Development Time | Longer (1 to 6 months) | Shorter (1 to 4 weeks) |

Supplier Role | Makes shirts from your design | Makes shirts from their design, you add logo |

Product Uniqueness | Your shirt is unique | Many brands may sell the same shirt |

Cost and Speed | Costs more and takes longer | Costs less and is faster |

Fabric Specification | You pick the fabric and details | Supplier has fabric choices ready |

Production Volume | Usually need to order more shirts | Good for smaller orders |

OEM gives you control and makes your shirt special. But it takes more time and money. ODM is faster and cheaper, but other brands may have the same shirt. Both ways help you grow your clothing business and keep good quality. Your choice depends on what you want for your brand.

OEM is best if you want:

A shirt that is only for your brand

Full control over design and fabric

To protect your design

ODM is best if you want:

To start selling shirts fast

Lower costs and smaller orders

Good, ready-made shirts

Note: Many brands use both ways at different times. You can start with ODM to try the market. Later, you can use OEM for special shirts as your brand grows.

Design and Customization

Design Control

You can help decide how your knit polo shirts look. This is true with both OEM and ODM. With OEM, you make your own designs for your shirts. You pick things like the collar and fabric. The factory follows your ideas and checks the shirts for quality. This way, you control how your shirts turn out. It helps your brand look different from others.

ODM also lets you change some things about your shirts. You start with a style the factory already has. You can add your logo or pick a new color. You can also choose the packaging. Many factories offer both OEM and ODM. They let you help with design choices. They use good fabrics and have skilled workers. This helps your shirts meet your brand’s needs.

Aspect | OEM Manufacturers | ODM Manufacturers |

|---|---|---|

Design Role | You provide the design | Manufacturer offers design options |

Customization | Full, based on your specs | Partial, based on catalog styles |

Brand Control | High | Moderate to High |

Quality Control | Strict, at every stage | Strict, at every stage |

Tip: If you want your shirts to be special, OEM gives you the most control. ODM is faster but still lets you make changes.

Customization Options

You can change many things about your knit polo shirts. This is true for both OEM and ODM. Custom orders let you pick from lots of choices. This helps your brand be unique. You can pick the knit pattern, like pique or jersey. You can choose the collar style that fits your brand. You can also pick the material, like 100% cotton or a blend.

Here are some common customization options:

Knit patterns: fine or coarse, like waffle or ribbed

Collar shapes: classic, Johnny, or banded necks

Sleeve trims and placket designs

Logo placement: embroidery, patch, or jacquard-knitted

Fabric weight: 220gsm to 300gsm for durability

Color options: fashion neutrals, seasonal tones, Pantone matching

Sizes: youth to adult, XS to 5XL

Packaging: OPP bags, hang tags, or gift-ready boxes

You can also add things like anti-wrinkle or quick-dry features. The factory can make a sample so you can check your design. This helps your brand give customers what they want. It also helps your shirts stand out in stores.

Note: Both OEM and ODM factories use new machines and skilled workers. They help you get good quality shirts fast, even if you want special details.

Cost and MOQ

Cost Factors

When you make knit polo shirts, many things change the price. Some things make shirts cost more or less. The table below shows what affects the price for OEM and ODM:

Cost Factor | Description / Impact | Example / Quantification |

|---|---|---|

Minimum Order Quantity (MOQ) | Buying more shirts at once makes each shirt cheaper. Small brands can order less, like 100–500 shirts, and save money. Big orders, like 5,000 shirts, can cost more for small brands. | |

Lead Times | How long it takes to make shirts changes the price. Waiting longer can cost more. Most factories take 15–60 days to finish. | 30–60 day lead times with 15% faster delivery impact |

Fabric Options | You can pick cotton, polyester, or recycled fabric. Using eco-friendly fabric costs about 15% more. | Sustainable fabrics raise costs by 15% |

Customization Levels | You can add logos, prints, or labels. You can change almost everything. If you design in-house, you save 15%. | 90% customization; design cost reduction by 15% |

Certifications | Factories with special certificates make better shirts. These certificates cost more but mean good quality. | Certifications ensure 95% quality compliance |

Production Capacity | Big factories make lots of shirts fast. This can help save money. | Facilities with ≥100,000 units monthly output |

Sustainability Practices | Using recycled fabric cuts pollution by 12%. It can cost more, but it helps the planet. | 10–15% recycled materials reduce emissions by 12% |

Global Supply Chain | Factories in special places pay less tax. This can save you about 10%. | Tariff-free zones save 10% |

You can save money by picking the right factory. If you use a factory in a tariff-free area, you save up to 10%. If you want eco-friendly fabric, you pay about 15% more. Adding special logos or getting certificates costs more, but it helps your brand look better.

Tip: If you do not need shirts fast, you can wait longer and pay less. Fast shipping costs more money.

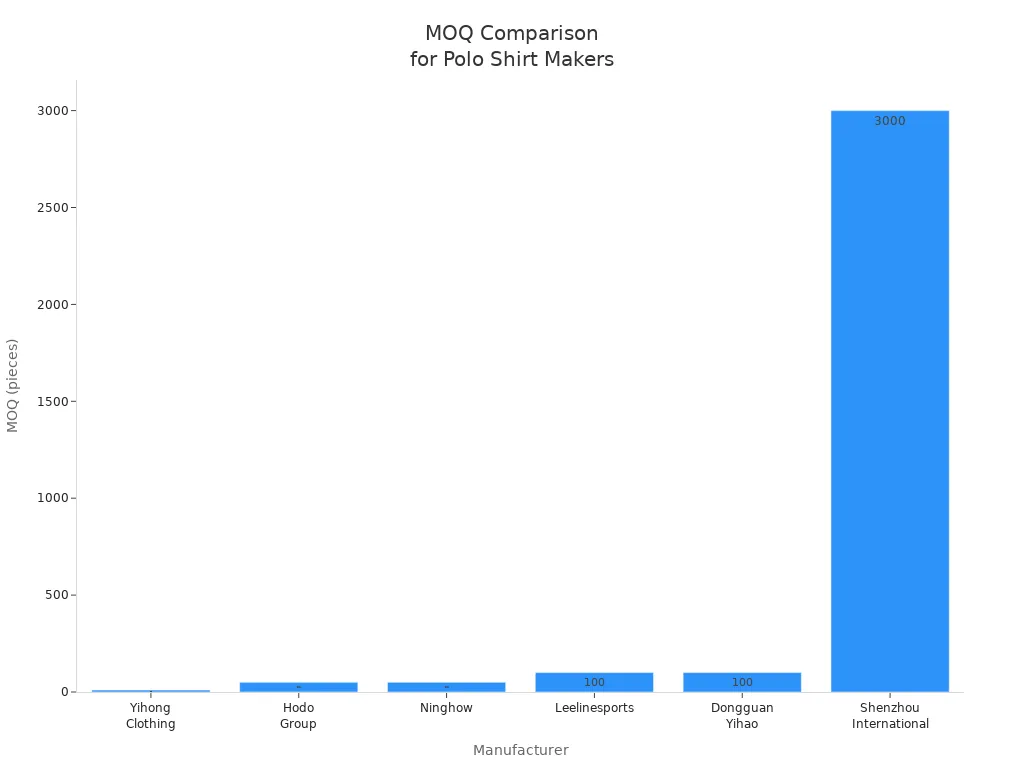

Minimum Order Quantities

MOQ means the smallest number of shirts you must buy. Both OEM and ODM have different MOQs. Small brands want low MOQs to try new ideas. Big factories want bigger orders, which is good for big brands.

Here is a table with common MOQs for different factories:

Manufacturer | MOQ Range (pieces) | Notes on MOQ Context |

|---|---|---|

Yihong Clothing | 10 per style | Very low MOQ, suitable for startups and small brands |

Hodo Group | 50 per style/color | Flexible MOQ for medium-sized businesses |

Ninghow | 50+ | Low MOQ with tiered pricing and sample options |

Leelinesports | 100 per design | Typical MOQ for bulk orders, flexible for samples |

Dongguan Yihao | 100-200 per style | Supports new brands with moderate MOQ |

Kuanyang | Fabric-based MOQ | Flexible MOQ for samples and testing |

Shenzhou International | 3,000 per style | High MOQ for large-scale, steady production |

Some factories let you order just 10 shirts. This is good if you are just starting. Other factories want you to order thousands, which is better for big brands.

If you want to spend less and not have too many shirts, pick a factory with a low MOQ. This helps you try new ideas and control your money before making lots of shirts.

Speed and Flexibility

Lead Time

When you plan your knit polo shirt launch, lead time matters. Lead time means how long it takes from placing your order to getting finished shirts. OEM and ODM models offer different timelines. If you choose OEM, you design your shirt from scratch. This process takes longer because you work on patterns, fabric, and samples. For small or medium OEM orders, some factories can finish in 7 to 20 days. Larger orders often take 30 to 90 days.

ODM production solutions move faster. You pick a ready-made design, so the factory skips many steps. For example, Taian BOWINS Garment can deliver ODM shirts about 20% faster than OEM. This speed helps you react to trends or restock quickly.

Here is a table showing lead times for different manufacturers:

Manufacturer | MOQ (pieces) | Lead Time (days) | Notes on OEM/ODM Lead Time Differences |

|---|---|---|---|

Taian BOWINS Garment | 500 | 30–45 | ODM customization 20% faster using CAD/CAM |

Shahi | 1,000 | 45–75 | OEM lead times for larger orders |

Esquel Group | 1,500 | 60–90 | OEM lead times for larger orders |

Youngone Corporation | 2,000 | 60–90 | OEM lead times for larger orders |

MAS Holdings | 1,000 | 45–75 | OEM lead times for larger orders |

Luen Thai Holdings | 1,500 | 60–90 | OEM lead times for larger orders |

Viyellatex Group | 2,000 | 60–90 | OEM lead times for larger orders |

Tip: If you want to launch your shirts fast, ODM is usually the quicker choice.

Flexibility

You need flexibility when you grow your brand or test new ideas. OEM gives you control over every detail. You can change the design, fabric, or logo. This helps you create a unique shirt. OEM factories often work with you on special requests and can adjust minimum order quantities if needed.

ODM offers flexibility in a different way. You can order smaller batches and get shirts faster. This model works well for startups or brands that want to test the market. You do not control every design detail, but you save time and money.

Here is a table comparing flexibility:

Model | Design Control | Customization | MOQ Flexibility | Lead Time Flexibility |

|---|---|---|---|---|

OEM | High | High | Moderate | Moderate |

ODM | Moderate | Low-Moderate | High | High |

Note: If you want full design freedom, choose OEM. If you want to move fast and order less, ODM fits better.

You can match your needs with the right production solutions. This helps you stay flexible and meet your business goals.

Intellectual Property

Ownership in OEM

When you choose oem for your knit polo shirts, you own the design. You create the patterns, pick the fabrics, and decide on every detail. The manufacturer only makes the shirts based on your instructions. You keep the rights to your designs, logos, and any special features you add. This means no other brand can legally copy your shirt if you protect your design.

You can register your design or logo as a trademark. This step helps you stop others from using your ideas. Many established brands use oem because they want to keep their products unique. If you want to build a strong brand, oem gives you the power to control your intellectual property.

Tip: Always ask your oem partner to sign a Non-Disclosure Agreement (NDA). This agreement keeps your designs safe.

Here is a quick table to show what you own with oem:

OEM Ownership Rights | Description |

|---|---|

Design | 100% yours |

Logo | 100% yours |

Patterns and Specs | 100% yours |

Finished Product | Unique to your brand |

Ownership in ODM

With odm, the manufacturer owns the original design. You pick a style from their catalog and add your logo or change colors. You do not own the base design. Other brands can buy the same shirt and make small changes. Your logo and packaging are yours, but the shirt style belongs to the odm supplier.

If you want a fast launch and do not need a unique design, odm works well. You save time and money, but you give up some control. You cannot stop others from selling a similar shirt. This model fits startups or brands that want to test the market before investing in full design rights.

Note: If you want to protect your brand, ask your odm supplier about exclusive options. Some offer limited runs or custom tweaks for extra cost.

Pros and Cons

OEM Pros and Cons

When you choose oem for your knit polo shirts, you get a lot of control. You design the shirt, pick the fabric, and decide on every detail. This works well if your brand wants something unique. Many established brands use oem because they want their shirts to stand out.

Pros of OEM:

You control the design and quality.

The manufacturer helps with material sourcing and pattern making.

You can scale up production as your brand grows.

You get expert advice on fabrics and construction.

Your shirts stay unique to your brand.

Cons of OEM:

You may face higher costs, especially if you run a startup or boutique.

Most oem manufacturers ask for higher minimum order quantities.

You depend on the manufacturer for quality and delivery.

Sharing your designs can risk your intellectual property.

Aspect | OEM Manufacturing Characteristics |

|---|---|

Customization | |

MOQ | Usually high, better for established brands |

Best for | Brands wanting unique, high-quality shirts |

Example: If you run a boutique brand and want a special knit pattern, oem lets you create it. If you own a startup, you might find the cost and order size too high at first.

ODM Pros and Cons

If you pick odm, you can launch your brand quickly. You choose from ready-made designs and add your logo. This model works well for startups and small brands that want to test the market.

Pros of ODM:

You get shirts faster, often in just a few weeks.

You can order smaller quantities, which helps new brands.

You save money because the designs and patterns are ready.

You use proven styles and fabrics.

Cons of ODM:

You have less control over the design.

Other brands may sell the same shirt style.

Your brand may not stand out as much.

You do not own the base design.

Aspect | ODM Manufacturing Characteristics |

|---|---|

Customization | Moderate – mostly colors, logos, packaging |

MOQ | Low, good for startups and boutique brands |

Best for | Brands wanting speed and low risk |

Scenario: If you start a new brand and want to test polo shirts, odm lets you try different styles with low risk. If your brand grows, you can switch to oem for more control.

ODM Clothing Production: Sourcing Tips

Finding a Manufacturer

You want your brand to do well, so picking the right manufacturer for odm clothing production matters a lot. Start by finding a manufacturer that does full-package odm services. This means they handle everything, like getting fabric, making clothes, checking quality, and shipping. When one company does all these jobs, you save time and make fewer mistakes.

Check if the manufacturer knows how to work with knit fabrics and clothes. Skilled workers and new machines help make better shirts. You should also think about where the factory is. If the factory is close to fabric or skilled workers, they can make your clothes faster and for less money.

Here are some steps to help you find a good odm clothing manufacturer:

Find manufacturers with certifications like ISO or OEKO-TEX.

Ask for samples to see if their clothes are good.

Look at their client list to see if they work with other brands.

Make sure they can change clothes to match your brand, like luxury, sports, or eco-friendly styles.

Pick a manufacturer with good management and happy customers.

Tip: A good manufacturer will answer your questions and show you how they make clothes. This helps you trust their odm clothing production.

Quality Assurance

You want your clothes to be high quality. Quality assurance is very important in odm clothing production. Manufacturers use different steps to make sure your shirts look and feel nice.

They check each shirt before shipping to find problems.

They make sure sizes are right and fit well.

They look at the fabric for holes, stains, or bad color.

They check the stitching to make sure seams are strong and last after many washes.

These steps help you give your customers great shirts. When you work with a manufacturer that cares about quality, your clothes stand out in stores.

Note: Always ask your manufacturer about their quality checks. Good odm clothing production means fewer returns and happier customers.

Decision Guide

Checklist

Picking between OEM and ODM can change your brand’s future. You want to make a smart choice for your next shirts. Use this checklist to see how both options compare:

Checklist Item | ODM Characteristics | OEM Characteristics |

|---|---|---|

Development Cost | Low, no need for R&D or original design | Higher, requires original design and development |

Time Efficiency | Faster time to market, pre-designed products | Longer setup time due to custom design and production |

Product Exclusivity | Limited, products often shared among brands | Full exclusivity, trademarks and IP rights belong to the brand |

Customization Level | Limited, mostly pre-produced with minor alterations | Full customization based on brand’s specifications |

Minimum Order Quantity | Generally lower, suitable for smaller orders | High, often requires large orders (e.g., 3000 pcs) |

Quality Control | Supplier controls most processes, may vary | Requires finding qualified manufacturers with high standards |

Supplier Capabilities | Focus on manufacturing pre-designed products | Requires skilled labor and supply chain management for custom products |

Compliance & Labeling | Must ensure supplier can meet labeling and testing standards | Brand responsible for ensuring compliance, often more complex due to custom specs |

You should check some things before you start selling your shirts. Make sure your supplier gives you real test reports early. Check that the fabric and colors are right when you get samples. Ask if they do extra tests like fire safety or water resistance. Make sure labels show the right fabric, washing steps, size, and where it was made. Give your supplier the final label design and where to put it.

Tip: Using a checklist helps you avoid problems and keeps your project moving.

Key Questions

Ask yourself these questions to help you decide:

Do you want a special design or is a common style okay?

How quickly do you need your shirts for your launch?

What is your budget for making and designing shirts?

How many shirts do you want to order?

Can your supplier meet all quality and safety rules?

Do you need full control of your brand’s ideas and logos?

Are you ready for hard supply chain work, or do you want it easy?

Thinking about these questions will help you choose the best way for your brand to grow.

You now understand the main differences between OEM and ODM for knit polo shirts. OEM lets you control the design. This is best for brands that want something special. ODM is good for new brands or small shops. It helps you start selling fast and saves money. Use the checklist to compare both choices. Talk to manufacturers who offer low minimum orders, good quality checks, and clear answers.

Next steps for brands:

Look at what the manufacturer has made before and check their samples.

See if they help with changes and use eco-friendly fabrics.

Reach out to suppliers like PAPAGARMENT or Runtang Textile for prices and samples.

Manufacturer | Services Offered | Contact/Link |

|---|---|---|

PAPAGARMENT | OEM/ODM, design team, samples | info@papagarment.com, WhatsApp +86 137 134 17179 |

Runtang Textile | OEM/ODM, flexible orders |

Tip: Keep talking with your manufacturer. This helps make sure your brand gets what it needs every time.

FAQ

What is the main difference between OEM and ODM for knit polo shirts?

You design your own shirt with OEM. The factory follows your ideas. With ODM, you pick a ready-made style. You add your logo or change colors. OEM gives you more control. ODM is faster and easier.

Can I order a small number of shirts with OEM or ODM?

Most ODM suppliers let you order small batches, sometimes as low as 10 pieces. OEM usually needs bigger orders, often 500 or more. If you want to test the market, ODM works better for small runs.

How do I protect my brand’s design when using a manufacturer?

Always ask your manufacturer to sign a Non-Disclosure Agreement (NDA). Register your logo and design as trademarks. This helps keep your ideas safe and stops others from copying your shirts.

Which model is best for a new fashion brand?

ODM fits new brands best. You launch quickly and spend less money. You can test styles before investing more. OEM works better when you want a unique design and have a bigger budget.

What fabrics can I choose for knit polo shirts?

You can pick from cotton, polyester, blends, or recycled fabrics. Many factories offer different weights and finishes. Ask for samples to check softness, stretch, and color before you order.