You want to launch your own line of 100 moq knitwear. Finding a manufacturer who accepts a 100 moq knitwear order can change how you grow your brand. Many small brands now use low moqs to test new styles and react fast to trends. With a 100-piece minimum, you can knit several designs at once, just like Shein does. This approach lets you try more products, see what sells, and avoid big risks. You do not need a huge budget to start. Explore online platforms, connect with local groups, and reach out to global knit suppliers. Take the first step and knit your ideas into reality.

Key Takeaways

A 100 MOQ means you must buy at least 100 pieces for each style or color. This helps small brands try new designs without spending a lot of money.

You can use online websites, local groups, and big places like India and the USA to find knitwear manufacturers with low minimum orders.

Make sure the manufacturers know how to handle small orders. Check if they have good quality control. See if they can make changes to fit your brand.

Always ask for samples before you order. This helps you check the quality and trust your supplier.

Talk clearly and be honest when you make deals. This helps you get a good price and build a strong, long-lasting relationship with your manufacturer.

100 MOQ Knitwear Basics

What Is Minimum Order Quantity?

You may see the term “minimum order quantity” or MOQ when you start looking for knit manufacturers. This number tells you the smallest batch a factory will produce for each design or color. In the world of knitwear, MOQs help factories stay efficient and cover their setup costs. Here are some key points to understand:

Factories set MOQs to spread out the cost of setting up machines and paying workers.

The more complex your knit design, the higher the MOQ may be.

Fabric suppliers also have their own minimums, which can affect your order.

Special features, like embroidery or prints, can push the MOQ higher.

Knitwear factories often need higher MOQs because their machines and processes are specialized.

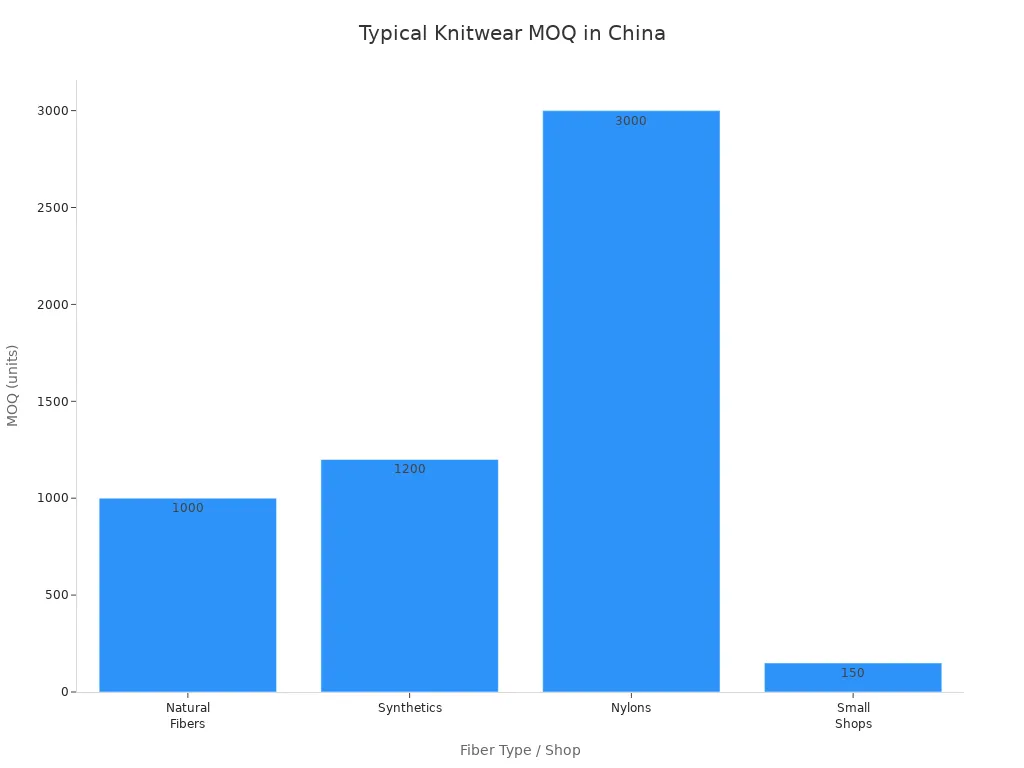

You will notice that knit factories in different countries have different MOQs. For example, in China, large factories may ask for 1000 units, but small shops can offer as low as 100-200 units. This chart shows typical MOQs for knitwear in major countries:

Why 100 MOQ Matters

Choosing a 100 moq knitwear supplier can make a big difference for your brand. Many startups and small brands want to test new knit styles without spending too much money. A 100 MOQ lets you do this. Here is why it matters:

Factories often set a 100 MOQ because of the time and labor needed for each knit style.

Fabric rolls usually come in minimum lengths, so your order must match these limits.

If you add special details to your knit, like zippers or graphics, the setup costs go up, and so does the MOQ.

For a new brand, a 100 MOQ means you do not have to buy too much at once. This helps you avoid extra stock and saves money.

You can try more knit designs and see what your customers like best.

Aspect | Low MOQ | |

|---|---|---|

Pros | Lower per-unit cost due to bulk production | Smaller upfront investment reduces risk |

Ensures steady supply for stable demand | Greater flexibility to adapt to market | |

Cons | High upfront costs, straining cash flow | Higher per-unit costs |

Risk of overstock if demand changes | Limited bargaining power | |

Best For | Businesses with predictable demand and financial resources | Startups, small businesses, or those testing products |

Tip: Working with a 100 MOQ knitwear manufacturer gives you the freedom to experiment with new knit ideas and grow your brand step by step.

How to Find 100 MOQ Knitwear

Online Platforms

You can look for 100 moq knitwear suppliers on big websites. These sites help you find factories that take small orders. Many new brands use these sites to get print-on-demand knit sweaters and print-on-demand knitwear. Here are some good places to start:

Alibaba: You can search for suppliers by minimum order, product, and country. It is easy to find knit factories that take 100-piece orders. You can check profiles and read reviews to pick good partners.

Sewport: Sewport has a list of checked manufacturers. You can use filters to find knitwear suppliers with low MOQs. The site helps with safe payments and is good for new brands.

Indiamart: Indiamart links you to Indian knit factories. You can message suppliers and ask about their minimums.

Hongyu Apparel: Hongyu Apparel is known for low MOQ clothing. It is good for brands that want small batches. They help you test new knit designs with samples.

Konsey Textile (Turkey) and Hook and Eye (UK): These companies care about quality and new ideas. They take small orders and help new brands.

Tip: Always use search filters to make your search easier. Look for suppliers who offer 100 moq knitwear or print-on-demand knit sweaters. This saves time and helps you find the right factory.

Local Associations

Local groups and business clubs can help you find knit suppliers with low minimums. These groups keep lists of trusted factories and help new brands. They also make sure the factories follow rules and make good products.

Manufacturer | Location | Specialty / Product Focus | MOQ Details | Additional Notes |

|---|---|---|---|---|

USA | Women’s fashion including knitwear | Low MOQ starting from 1 piece | 41 years experience, fast sample turnaround, focus on craftsmanship | |

LA Fashion Source | USA (California) | Wide apparel range including knitwear | Flexible MOQs, startup friendly | Pattern making, fabric sourcing, retail-ready packaging |

Good Clothing Company | USA | Eco-friendly, organic knitwear | Low MOQs for small batch production | Sustainable materials, ethical practices |

Apparel Kingdom | USA | Children’s clothing (including knitwear) | Low MOQ starting at 30 pieces | Focus on safety compliance and quality checks |

Sewport (Platform) | Online | Connects brands with manufacturers | Filters for low MOQ manufacturers | Verified manufacturers, secure payment, supports startups |

Local business clubs also help you find knit factories in your country. They only list factories that are checked and follow the rules. This lowers risk and helps you find good partners for 100 moq knitwear.

You get a list of trusted suppliers.

You can see if the factory follows the law and safety rules.

You find partners who know how to work with small batches.

Global Manufacturing Hubs

Some countries are famous for making knitwear. If you want print-on-demand knitwear or print-on-demand knit sweaters, you should know where to look. India is a top place for knitwear, especially in Tiruppur. This city makes most of India’s knitwear and takes both big and small orders.

Country | Knitwear Hub | MOQ (pieces) | Notes |

|---|---|---|---|

India | Yes | Flexible | Tiruppur supports low MOQs, ideal for small brands |

Mexico | No | 100-500 | Low MOQs, but not a knitwear hub |

Bangladesh | No | High volume, not ideal for small orders | |

China | No | >1,000 | Large capacity, but higher MOQs for knitwear |

Others | No | Higher | Not focused on knitwear or have higher minimums |

Factories in China, Bangladesh, and Vietnam want bigger orders. For example, Chinese factories may ask for 500 pieces per style. In Bangladesh and Vietnam, you may need to order 1,000 or more. If you want less than 1,000 pieces, try local or Indian suppliers.

Note: For small orders like 100 moq knitwear, India and the USA are more flexible. You can also find print-on-demand knitwear services in these places.

Online Communities

Online groups and forums give you real stories and tips. The Fashion Incubator website is a popular place for making clothes. People share advice about finding knit factories with low MOQs. You can ask questions about print-on-demand knit sweaters and get names of good suppliers.

Forums and Facebook groups help you learn from other brands.

You can read reviews and see what others think before you choose.

These groups help you trust suppliers and avoid mistakes.

Tip: Use online groups as a support tool. Mix their advice with your own research on websites and lists. This helps you find the best 100 moq knitwear suppliers.

Evaluating Manufacturers

Experience with Minimum Orders

When you search for a knit manufacturer, see if they know how to handle small orders. Some factories only work with big brands and large batches. Others have experience making just 100 pieces at a time. Ask them to show proof of past work with small brands. You can also ask for names of other clients who ordered print-on-demand knit sweaters or print-on-demand knitwear. Factories with this kind of experience know what new brands need. They can help you avoid mistakes and make sure your knit products arrive on time.

Quality and Customization

Quality is very important when you order small batches of knit products. You want every item to look nice and feel good. Here are some ways to check if a manufacturer has good quality control:

Pick manufacturers who have quality certifications like ISO.

Ask them to show you papers that prove these certifications.

If you can, visit the factory and watch how they check quality.

Look at the stitching, size, and fabric before they send your order.

Keep checking the quality and tell the supplier if you see problems.

Stay in contact with the factory to make sure they meet your needs.

Use lists from local groups to find trusted knit suppliers.

Customization is also key for your brand. Factories with low minimums often let you choose more custom options for knit sweaters. You can see the differences in this table:

Manufacturer Type | MOQ Range | Customization Flexibility | Cost Implications | Notes on Complexity and Negotiation |

|---|---|---|---|---|

High MOQ Manufacturers | Less flexible, extensive customization | Lower per-unit cost due to economies of scale | Require large orders to offset tooling and mold costs; metal products often have high MOQs | |

Low MOQ Manufacturers | 50 to 200 units | More flexible, suitable for startups | Higher per-unit cost due to smaller runs | Accommodate smaller batches; higher setup expenses; often newer or smaller producers |

Impact of Customization | Increases MOQ | Complex shapes, multi-materials, electronics | Requires specialized tooling, molds | Custom molds increase fixed costs, pushing MOQ higher |

Regional Differences | Varies | Chinese suppliers may reduce MOQs by 15-25% | Vietnamese factories tend to have higher MOQs and less flexibility | Negotiation possible mainly for first proof orders |

Advanced Manufacturing Tech | Enables smaller runs | 3D printing and modular production disrupt traditional MOQ logic | No expensive tooling or lengthy setup | Allows production of customized items in smaller quantities |

Requesting Samples

Always ask for samples before you make a big order. This helps you check the real quality of the knit products. The steps usually go like this:

Step/Aspect | Description |

|---|---|

Material Submission | Send all materials at the start of the project to avoid delays and keep the process on track. |

Sample Request | Request Pre-Production Prototype (PP Sample) to ensure alignment before production. |

Sample Evaluation Criteria | Assess fabric quality, stitching, finishing, sizing, and fit. |

MOQ Definition | MOQ stands for Minimum Order Quantity; relevant for knitwear with 100 MOQ. |

Raw Material Sourcing | Use in-stock fabric for faster sampling; custom sourcing may increase lead time. |

You should check the fabric, stitching, and fit of each sample. Start with a small order to see if the factory is reliable. Make clear rules for price, delivery, and quality. Keep talking with your supplier to build a good partnership. This careful process helps you get the best results for your knit brand.

Building Relationships

Negotiating 100 MOQ

When you want to work with a knit manufacturer, you need to show that you are serious about your business. Many factories set their minimums high, but you can often negotiate for a 100 MOQ if you use the right approach. Here are some ways to help you get the deal you want:

Show that you are ready to pay a higher price per knit item. This helps the factory cover its costs and makes it more likely to accept your order.

Team up with other brands to combine orders. If you all want knit products, you can reach the minimum together.

Ask for a longer production timeline. This gives the factory more time to fit your knit order into their schedule.

Promise to work with the factory for future orders. When you talk about long-term plans, factories may lower their minimums.

Be clear about what you need. Explain your design, delivery time, and payment terms from the start.

You can also split your order or payment. Some suppliers let you pay half now and half later. If you share your sales forecast, the factory can plan better and may agree to a lower MOQ. Sometimes, factories use no minimum order quantities if you meet a certain dollar amount instead of a unit count.

Tip: Write a personal letter to the factory. Tell them about your brand and why you want to work with them. This builds trust and helps you stand out.

Communication Tips

Good communication helps you avoid mistakes and keeps your knit project on track. You should always use clear and simple language when you talk to your manufacturer. Here are some tips to help you build a strong partnership:

Give the factory detailed tech packs. Include photos, diagrams, and written instructions for your knit designs.

Set clear quality standards. Use a checklist to make sure every knit item meets your needs.

Ask for photos and videos during production. This helps you spot problems early.

Respect cultural differences, especially if your factory is overseas. Learn how they do business to avoid confusion.

Start with a small knit order. This lets you test the factory’s quality and how well they communicate.

Stay professional and open. Respond quickly and keep your requests clear.

Plan for the future. Choose a manufacturer who can grow with your brand and handle bigger knit orders later.

Note: Clear communication at every step helps you get the knit products you want and builds a lasting relationship with your supplier.

Common Challenges

Pricing for Low MOQ

Ordering knitwear with a 100 MOQ brings unique pricing challenges. You may notice that the cost per unit is higher than with larger orders. Factories must cover setup and labor costs, even for small batches. Here are some common reasons why prices can rise for low MOQ knitwear:

Complex knitwear designs, like socks or beanies, often require more setup and labor, which increases both MOQ and cost.

Fabric suppliers usually sell fabric by the roll (about 100 meters per color). If your order does not use most of the roll, you may pay extra or need to order more fabric.

Special details, such as appliqué or sublimation printing, add to setup time and push the MOQ to at least 100 units.

Fixed costs, like pattern development and machine setup, stay the same no matter how many pieces you order. This means each item costs more in a small batch.

Factories set MOQs per design and color. You cannot split your 100 units across many colors, which can make inventory planning harder.

Note: You may see prices for 100 MOQ knitwear range from $29 to $69 per unit. Larger orders often cost less per piece because factories can spread out their fixed costs.

Region / Factory | MOQ per color/style | Production Lead Time (weeks) |

|---|---|---|

China Guangdong | 100 units | 4-6 |

South Korea Busan | 250 units | 6-8 |

Honduras Choloma | 300 units | 4-5 |

Peru Lima | 300 units | 4-6 |

Vietnam Thai Nguyen | 1,000 units | 4-6 |

Ensuring Quality

Quality control is vital when you order small batches. You want every knitwear piece to meet your standards. You can take several steps to reduce quality risks:

Set up inspections at key points: when materials arrive, during production, and before shipping.

Train your team and factory workers on what good quality looks like.

Use digital tools, like mobile apps, to track defects and keep records.

Ask customers what they want early in the process to avoid mistakes and returns.

Watch quality numbers, such as defect rates and returns, for each batch.

Collect feedback from buyers after delivery to spot problems and improve.

Work closely with your supplier to understand their process and find ways to use materials better.

Tip: Brands that use multi-stage quality checks and involve customers before shipping often see fewer returns and happier buyers.

You can find a good knitwear manufacturer with a 100 MOQ by taking some simple steps. First, check if the factory makes good products and can handle your order size. Make sure their minimum order fits what you need. Pick a local manufacturer if you want your order faster and want to check quality more easily. Local factories also give you more personal help. Try to visit the factory if you can. Meeting them helps you work better together. Choose factories that care about the planet and let you change your designs. Some factories do everything in one place. This helps small brands get good knitwear with lower minimums. It also lowers your risk and helps you compete with bigger brands. Keep trying, use these tips, and you can make your knitwear ideas come true!

FAQ

What does 100 MOQ mean for my knitwear order?

100 MOQ means you must order at least 100 pieces of each style or color. Factories set this number to cover their costs. You can test new designs without spending too much money.

Can I mix different colors or sizes in a 100 MOQ order?

Most factories want you to order 100 pieces per color and style. Some may let you split sizes within one color. Always ask your supplier about their rules.

How do I check if a manufacturer is trustworthy?

You can read reviews, ask for references, and request samples. Trusted factories show certificates and answer your questions quickly.

Tip: Join online groups to see what other brands say about the factory.

Why is the price higher for low MOQ knitwear?

Factories spend time and money setting up machines. Small orders do not spread out these costs. You pay more per piece, but you avoid buying too much at once.

What should I include in my first message to a manufacturer?

You should share your design idea, order quantity, and timeline. Add clear photos or sketches.

Ask about their experience with small orders.

Request a sample.

Tell them about your brand and goals.