Choosing the best knitting lace trim factory needs careful thought about many things. Top factories are not the same in materials, machines, and custom choices. Some use high-quality fibers like silk or organic yarns. Others use cheaper synthetic blends. Factories also have different ways to make products, order sizes, and wait times. Looking at these things helps buyers pick a factory that fits their quality needs, budget, and service wants.

Key Takeaways

Make sure you know what your project needs. Think about lace type, width, color, and how much you need. This helps you talk to factories and avoid mistakes.

Pick a factory that fits your lace use. It can be for fashion, home décor, or special uses. This helps you get the best quality and design.

Look at the materials and how the lace is made. Check for certifications like OEKO-TEX® and GOTS. These show the lace is safe, strong, and good for the environment.

Compare prices by looking at quality and extra services. Also, check the smallest order you can make. This helps you get the best deal for your money.

Test the factory’s service by seeing how they talk with you. Check how fast they work, if they can customize, and if they help after you buy. This helps you build a good partnership.

Define Your Needs

Project Requirements

Every buyer should first think about what their project needs. They need to pick the type, width, and color of lace trim. Some projects use thin lace for baby clothes. Other projects need wide lace for home décor or fashion. Buyers also need to know how much lace they want. If they order a lot, they might get a discount. Small orders may not work with every factory.

Tip: Making a checklist helps buyers talk clearly with any knitting lace trim factory.

Key points to think about:

The width and pattern you want

Color and dyeing choices

How much and how often you will order

Any special finishes or treatments

A clear plan saves time and avoids mistakes. It also helps factories give the right prices and samples.

Intended Use

How you will use the lace trim is very important. For example, lace for kids’ clothes must be safe and soft. Lace for lingerie or wedding dresses needs fine materials and pretty designs. Lace for home things, like curtains, should be strong and easy to wash.

Some factories are good at certain kinds of lace or uses. Buyers should pick a knitting lace trim factory that matches their needs. This helps make sure the lace works well and looks nice.

Fashion and clothes

Home décor

Crafts and accessories

Industrial or technical uses

Picking the right factory starts with knowing your project and its goal. This helps you get better results and makes production easier.

Quality Factors

Materials

The materials used change how lace trims feel and last. Good knitting lace trim factories pick materials that fit the final use and style. Some common base fabrics are net knitting cloth, cotton cloth, and water-soluble base cloth. These fabrics help hold embroidery and patterns.

Nylon and spandex make lace trims stretchy and strong.

Rayon, cotton, and polyester make lace trims soft and tough.

Gold and silver threads make lace trims look fancy and shiny.

Eyelash lace is usually made with nylon or polyester. Some factories add elastic fibers to make lace softer and more comfy. This is important for nice clothes and underwear. Galloon lace trims use nylon and spandex for pretty designs and to bend easily.

Craftsmanship

Craftsmanship makes lace better or worse. Skilled workers use special machines to make neat, detailed patterns. They look for mistakes and check quality often. Factories with good teams make lace trims with smooth edges, even stitches, and the same color. Careful work makes lace look nice and last longer.

Note: A knitting lace trim factory known for good craftsmanship gives better lace and fewer problems.

Certifications

Certifications show a factory cares about safety, quality, and the planet. Buyers should check for these when picking a supplier:

Certification Name | What It Means | Why It Matters |

|---|---|---|

No harmful stuff in textiles | Trusted for lace, like polyester and cotton | |

GRS (Global Recycled Standard) | Uses recycled materials and saves resources | Helps make lace trim more eco-friendly |

GOTS (Global Organic Textile Standard) | Organic from start to finish | Shows the factory uses organic and green textiles |

ISO 9001 | Good quality control system | Makes sure products are always good |

REACH Compliance | Follows chemical safety rules | Needed for selling in Europe, keeps lace safe |

Certifications like OEKO-TEX® Standard 100 and ISO 9001 help buyers trust the lace is safe and good. GRS and GOTS show the factory cares about the earth. REACH compliance is needed to sell lace in Europe.

Price Comparison

Cost Breakdown

Factories decide lace trim prices in different ways. The quality of materials and how hard the design is can change the price. The way the lace is made also matters. Factories that use better fibers or new machines charge more money. Simple lace trims with easy patterns cost less. Buyers should ask each supplier for a clear price list. This list should show the price for each yard, setup costs, and extra fees for special colors or packaging.

Tip: Ask for a full price list to see all costs and compare factories easily.

Value for Money

A cheap price does not always mean it is a good deal. Buyers should check what they get for the money. Good lace trims last longer and look nicer. Some factories give free samples or discounts for big orders. Others help more or ship faster. Buyers should think about these extras when looking at the price. Picking a knitting lace trim factory with a good name often gives better value, even if it costs more at first.

Look at quality, service, and price together.

See if the factory gives free samples or quick shipping.

Read reviews to find out if other buyers liked what they got.

Minimum Orders

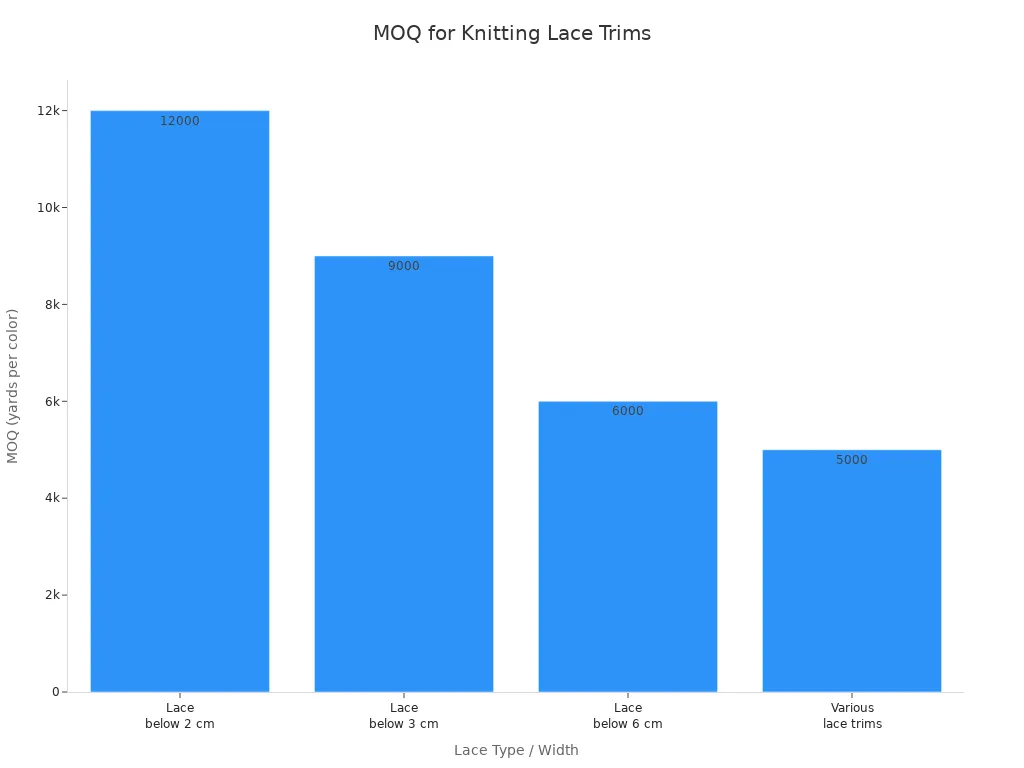

Factories usually have minimum order quantities, called MOQs, for lace trims. These rules help them keep production costs low. The MOQ can change based on lace width and type. Buyers should check if the factory’s MOQ fits their needs. The table below shows common MOQs for big factories:

Lace Width / Type | |

|---|---|

Lace below 2 cm width | 12,000 yards per color |

Lace below 3 cm width | 9,000 yards per color |

Lace below 6 cm width | 6,000 yards per color |

Various lace trims (e.g., floral mesh, elastic lace for lingerie) | 5,000 yards MOQ |

Some buyers may think these MOQs are too high for small projects. If so, they should look for factories with lower MOQs or work with distributors.

Service Evaluation

Communication

Good communication makes a knitting lace trim factory stand out. Buyers should get fast replies to their questions. Top factories often send samples before big orders. This lets buyers check the quality first. A factory that answers quickly and sends samples on time cares about customers.

Tip: Always ask if the factory gives samples and how fast they answer emails or messages.

Customer reviews and ratings help buyers see if service is good. Good reviews mean the factory listens and fixes problems fast.

Lead Times

Lead time is how long it takes to get your order. Most big factories, like Prowong Textile, take 7 to 10 days for samples. They need 4 to 5 weeks to finish making the order. The time can change if the design is hard or the order is big. Buyers should ask for clear timelines before they order. This helps stop delays and keeps projects on time.

Customization

A good knitting lace trim factory lets you change many things. Some choices are:

Use your own designs

Change lace width up to 130cm

Switch base fabrics, like mesh or cotton voile

Find fabrics like your samples

Lab dips for the right color

Make new designs from your ideas

Keep your designs private

Use eco-friendly materials

Test for quality, like color fastness and stability

These options help buyers get lace trims that fit their needs and style.

After-Sales

After-sales service is important for long-term business. Good factories help if there are problems after delivery. They answer care questions, handle complaints, and fix bad products. Buyers should check if the factory helps after the sale. Reading reviews can show if the factory supports its products.

Technology & Capacity

Equipment

Modern knitting lace trim factories use advanced machines to make good lace trims. Many factories have computerized crochet machines with special jacquard systems. These machines help make lace faster and with more details.

Some common machines are:

Jacquardtronic machines for hard lace patterns

Raschel machines for simple, cheaper lace trims

Jet dyeing machines for exact colors

Inspection machines to check quality

Factories like Pure Textile in China have over 100 warp knitting machines. Some factories buy Swiss Saurer embroidery machines to make more lace and waste less. These machines help factories fill big orders and keep lace quality the same.

Innovation

Innovation helps the lace trim industry get better. Top factories build new machines that mix lace styles and give more design choices. For example, MAS Holdings uses natural dyeing to make 32 natural lace colors.

Factories use computers and automation to change patterns fast and make fewer mistakes. Dah Heer Industrial Co. makes machines that create seamless fabrics. This makes lace more comfy and cuts down on waste.

Innovation Aspect | Description |

|---|---|

Hundreds of computerized embroidery and jacquard machines, plus advanced dyeing lines | |

R&D and Design | Teams of experts create new designs monthly and manage large digital pattern libraries |

Customization | Factories offer custom embroidery, strong copyright protection, and multiple development modes |

Production Speed | Large-scale capacity, fast sampling, and efficient logistics |

Quality and Service | Rigorous quality control and comprehensive after-sales support |

Eco-Friendly Options

Many buyers now want eco-friendly lace trims. Factories make lace from recycled or organic materials. Some use natural dyes to use fewer chemicals and save water.

More people want cheap and green lace trims. Buyers pick factories that use green technology and have GRS or GOTS certifications. These steps help the planet and meet what buyers want today.

Tip: Pick a knitting lace trim factory that uses new technology and eco-friendly ways. This helps you get good lace and care for the earth.

Choosing a Knitting Lace Trim Factory

Picking the right knitting lace trim factory takes careful steps. Buyers should look at different factories and compare them. They can use real stories to help decide. Factories from around the world and local ones, like those on Alibaba, each have good points. The next parts give helpful tips and tools for making this choice.

Comparison Table

A comparison table lets buyers see what each factory is good or bad at. This makes it easy to spot important things like product types, how things are made, and where they can be used. Buyers can use the table to check factories from many places or websites.

Criteria Category | Key Elements Included |

|---|---|

Product Details | Types of lace trims, fabric composition, width, patterns |

Technical Parameters | Materials used (cotton, silk, polyester, nylon), production methods (computerized knitting, dyeing), certifications (OEKO-TEX), minimum order quantities (MOQ) |

Application Scenarios | Fashion apparel (wedding gowns, lingerie), home textiles, bridal wear, accessories |

Pros | Quality, customization options, sustainability, comfort, durability |

Cons | Minimum order quantities, color options, lead times, shipping costs, cost of premium materials |

Additional Factors | Eco-friendliness, production technology, product range |

Tip: Buyers should fill in this table for every factory they look at. This helps them compare and pick the best one for their needs.

Case Studies

Case studies show how buyers pick a knitting lace trim factory for special jobs. These stories show why custom orders, good quality checks, and on-time delivery matter. For example, one supplier changed fabric size and features for a client. This helped stop waste and made sure the fabric fit right. The factory checked materials and finished products many times to keep quality high. They also made sure to deliver on time so the client’s work went smoothly.

Aspect | Description |

|---|---|

Customization | Tailoring fabric dimensions and properties to client specifications to minimize waste and meet needs. |

Quality Control | Multi-step inspections: incoming material certification, in-process knitting and bonding checks, and final visual and physical assessments to ensure product reliability. |

Delivery Schedule | Alignment with Just-In-Time (JIT) production timelines to support seamless client manufacturing operations. |

Manufacturing Process | Includes material preparation (polyester yarns, hydroentangling for spunlace), fabric production (warp-knit and spunlace processes), roll preparation, packaging, and labeling. |

Client Application | Automotive seat trim covers and molded interior components requiring durability, comfort, and structural integrity. |

Volume and Scale | Millions of yards supplied across multiple purchase orders, demonstrating capacity and reliability. |

The Acme Mills story shows how a buyer can get help from a factory that knows a lot about making and checking fabric. By picking factories that offer custom work and steady results, buyers can get lace trims that look good and work well.

Step-by-Step Approach to Factory Selection

Experts say buyers should follow clear steps to pick a knitting lace trim factory. This helps lower risks and builds trust between buyers and factories.

Pre-Audit Preparation: Check the factory’s papers, like certifications and licenses. Learn what the client wants and make a checklist.

Initial On-Site Inspection: Look at the factory’s buildings, machines, and how workers are treated. Check if the raw materials are good.

Quality Control Assessment: Watch how the factory makes and tests products. Check for mistakes to make sure quality stays the same.

Compliance Check: Make sure the factory follows rules for the environment, workers, and safety.

Production Capacity Evaluation: See how much the factory can make. Find any slow spots and check how long orders take.

Final Report and Recommendations: Write down what you found, list good and bad points, and talk with the client to choose a partner.

Note: Buyers who use these steps can make smart choices and build strong relationships with their knitting lace trim factory.

Picking the best knitting lace trim factory takes a few steps. Buyers need to know what they want first. They should look at quality and price and also check the service and machines. It helps to ask for real fabric samples. Buyers should write down what they need in tech packs. They can test samples to see if they are right. Reading customer reviews is smart. Approving samples before big orders stops problems. When buyers think about all these things, they can pick a factory that fits their project.

FAQ

What is the typical lead time for knitting lace trim orders?

Factories usually need about a week for samples. Making the full order takes about a month. If the design is hard or the order is big, it can take longer. Buyers should always check the timeline before they order.

How can buyers check the quality of lace trims before ordering?

Buyers can ask the factory for samples. They should look at the lace to see if the stitches are even. The edges should be smooth and the color should match everywhere. Reading what other customers say can also help buyers know if the lace is good.

Do factories offer eco-friendly lace trim options?

Many factories now make lace trims with recycled or organic materials. Buyers should look for special certifications like GRS or GOTS. These choices help protect the planet.

What is the minimum order quantity (MOQ) for custom lace trims?

Factories have different MOQs for each lace type and width. Some factories want buyers to order between 5,000 and 12,000 yards for each color. Buyers should ask about the MOQ to make sure it fits their project.

Can factories create custom lace designs?

Most top factories let buyers make custom lace. Buyers can send in their own designs and pick colors and materials. Factories often give samples and lab dips so buyers can check before saying yes.