Choosing the right small batch natural fiber knit manufacturer is important. It helps shape your brand’s reputation from the beginning. You need a manufacturer who cares about quality. Even small mistakes, like uneven color or fabric flaws, can hurt how people see your brand. Find a manufacturer that cares about ethical practices. This means fair wages and safe workspaces. These things help build trust and match your brand’s values. Good communication is important too. Flexible minimum order quantities help you start small. A focus on sustainability lets your brand grow with confidence.

Key Takeaways

Pick a small batch natural fiber knit manufacturer who cares about quality, ethics, and the planet. This helps your brand look good.

Small batch manufacturers let you order small amounts. You can try new designs and not have too much extra stock. You also get to choose fabric and style.

Find manufacturers with good certifications. They should share where they get fabric, treat workers fairly, and help the environment.

Ask for samples and check references. Make sure the knitwear is good and matches your design before you order a lot.

Talk often with your manufacturer. Get updates, share your thoughts, and build trust. This helps your brand grow.

Small Batch vs. Large Batch

Minimum Orders

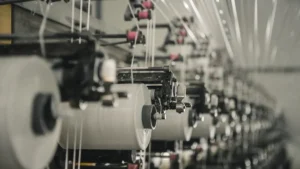

When you look for a knitwear manufacturer, you will notice a big difference in minimum order quantities. Small batch knitwear manufacturers often let you start with as few as 50 to 500 pieces. This is great if your brand wants to test new knitwear designs or try out different fabric blends. Large batch knitwear manufacturers usually want you to order 500 to 10,000 pieces at once. They need these bigger orders to cover their setup costs and keep their fabric machines running smoothly. Here’s a quick table to help you compare:

Manufacturer Type | Typical MOQ Range | Notes |

|---|---|---|

Small Batch Manufacturer | 50 to 500 units | Custom knitwear, flexible for new or small brands |

Large Batch Manufacturer | 500 to 10,000 units | Needs big orders, better for established knitwear brands |

Cost and Flexibility

Small batch knitwear production gives you more flexibility. You can change your fabric choices or knitwear styles quickly. If you want to try a new fabric or a fresh knitwear pattern, you do not have to wait for a huge order to finish. The cost per knitwear piece is higher in small batches, but you avoid the risk of leftover fabric or unsold knitwear. Large batch knitwear production lowers the cost per piece, but you must commit to a lot of fabric and knitwear at once. If your brand is just starting, small batch knitwear lets you stay nimble and adjust to what your customers want.

Tip: Small batch knitwear manufacturers often use new technology, like seamless knitting, to speed up production and handle custom fabric requests. This means you get your knitwear faster and can react to trends.

Brand Suitability

Small batch knitwear works best for brands that want to stand out. If you care about quality, unique fabric, and quick changes, small batch is for you. Many small brands use small batch knitwear to test new fabric blends or limited-edition knitwear collections. You can control your fabric choices and make sure every knitwear piece matches your brand’s values. Large batch knitwear suits brands that need thousands of the same fabric and style. These brands save money on each knitwear item but risk having extra fabric or unsold knitwear if trends change. Small batch knitwear helps you stay flexible, reduce waste, and keep your fabric choices fresh.

Small Batch Natural Fiber Knit Manufacturer Benefits

Quality Control

When you pick a small batch natural fiber knit manufacturer, you can watch each step closely. Workers check every fabric piece by hand. They look for problems in the fabric and fix them right away. This careful work means your knitwear is made well. You can trust that the fabric is chosen with care. The natural fibers are handled by skilled people. Many brands say this quality control makes knitwear last longer. You can see the difference in the fabric, stitching, and how well it is made. The focus on artisan craftsmanship helps your knitwear stand out. You also get to know your manufacturer better. This helps keep your fabric and quality high.

Note: Small batch knitwear makers often use local fabric and skilled workers. This keeps the quality high and helps keep old fabric skills alive.

Sustainability

Sustainability is a big reason to choose a small batch natural fiber knit manufacturer. These makers use less water and do not make toxic waste. Some brands use 60% less water to make their knitwear. They pick natural dyes, so there is less water pollution. This also makes the fabric safer for your customers. There is less fabric waste because they use all the yarn and even reuse scraps. Many knitwear brands use certified sustainable materials like organic cotton, alpaca, and recycled fabric. They help local farms and use eco-friendly ways to make knitwear. Certifications like GOTS, OEKO-TEX, and Fairtrade show your knitwear meets high standards. When you pick sustainable fabric, you help the planet and support fair work.

Common sustainable certifications for knitwear:

GOTS (Global Organic Textile Standard)

Fair Trade

RWS (Responsible Wool Standard)

Customization

You want your knitwear to fit your brand’s style. Small batch natural fiber knit manufacturers make this simple. They let you pick custom fabric, designs, and even sizes. You can work with them to choose the fabric, color, and style you want. If you need a special fabric blend or a new knitwear pattern, they can help. These manufacturers use new technology to make custom knitwear fast. You can try new designs without waiting for a big order. This flexibility lets you follow trends and listen to customer feedback. Working closely with your manufacturer means you can change your fabric or design anytime. Custom knitwear helps your brand stand out and keeps customers coming back.

Benefits of custom knitwear:

Pick your own fabric and design

Try new knitwear ideas in small amounts

Change fabric or design quickly

Offer special knitwear collections

Tip: Custom knitwear from a small batch natural fiber knit manufacturer lets you control every part, from fabric to design. This much choice is hard to get with large batch production.

Choosing a Knitwear Manufacturer

Research and Shortlist

Begin by making a list of possible knitwear manufacturers. Look for companies that make small batch knitwear with natural fibers. Check their websites and social media pages. See if they talk about where their fabric comes from. Look for information about sustainability and custom knitwear. Read reviews from other brands. Ask people in the knitwear industry for advice. Make sure each manufacturer lets you customize and order small amounts. This helps you try new knitwear ideas without spending too much.

When you do your research, keep these things in mind:

Does the manufacturer share clear details about fabric sourcing and how they make knitwear?

Do they talk about being sustainable or having certifications?

Can you find information about their custom knitwear services?

Are their minimum order amounts low enough for you?

Do they use local fabric or have microfactories to save time and lower pollution?

Pick the knitwear manufacturers that fit your brand’s values and needs. Focus on those who care about quality, the planet, and fair work.

Evaluate Experience

You need a knitwear manufacturer who knows how to make small batches with natural fibers. Good brands check this in a few ways:

See how long the manufacturer has been working. Look at their past clients to see if they have helped brands like yours.

Check their business licenses and certifications. Look for ISO 9001 or ISO 14001 to show they care about quality and the environment.

If you can, visit their factory. Watch how they handle fabric and check the work area.

Ask for references from other brands. Talk to these brands about quality and if orders arrive on time.

Look at their website and social media. A good manufacturer will look professional online.

Ask for samples. Check the fabric, stitching, and if the knitwear matches your design.

Think about using a third-party inspector to check quality.

Review their skills, fabric sources, and how they test for strength and performance.

Make sure they can handle your order size and finish on time.

A good knitwear manufacturer will answer your questions and show proof of their experience. They should be open about fabric sourcing and custom knitwear.

Request Samples

Always ask for samples before you decide. Samples show you the real quality of the knitwear and fabric. You can feel the fabric and check the color and stitching. Make sure the knitwear matches your design and fabric choices. Test the fabric for shrinking, color fading, and strength. If you want custom knitwear, ask for a sample with your fabric and design. This step helps you avoid problems and makes sure the manufacturer can do what you want.

Tip: Good knitwear manufacturers send samples fast and answer your questions about fabric and production. If they take too long or avoid your questions, it could be a warning sign.

Check Ethics and Sustainability

Ethical work and sustainability are important for your brand and customers. Ask each knitwear manufacturer how they treat workers, get fabric, and handle waste. Many brands find it hard to check these things, especially with factories far away. You can avoid problems by asking for certifications and audits from outside groups.

Here are some top certifications to look for:

Certification Name | What It Certifies / Focus Areas | Verification / Audit Focus |

|---|---|---|

Global Organic Textile Standard (GOTS) | Organic textiles, covers entire process from farming to manufacturing | Independent audits, license number, supplier database |

Fair Trade Certification | Fair labor practices, sustainable income, social empowerment, environmental stewardship | Independent audits, updated requirements on workers’ rights and supply chain ethics |

SA8000 | Social accountability, labor rights, health and safety, child labor, forced labor | Continual management improvement, supply chain performance audits |

Organic Content Standard (OCS) | Verification of organic content and chain of custody in non-food products | Third-party audits each stage to maintain organic content identity |

Global Recycled Standard (GRS) | Recycled content, social and environmental practices, chain of custody, chemical restrictions | Certification at all production stages, on-site visits and document checks |

Recycled Claim Standard (RCS) | Verification of recycled input materials in products | Third-party certification, on-site visits, document collection; traceability of recycled content |

Sedex | Ethical business practices and supplier monitoring | Standardizes social audits, shares supplier audits to promote transparency |

WRAP (Worldwide Responsible Accredited Production) | Apparel, footwear, sewn products focusing on human rights and ethical production | Certification based on 12 principles with multiple levels (Platinum, Gold, Silver) |

Ask for proof of these certifications and check if they are still valid. Outside audits help you trust what the manufacturer says. Some brands use digital tracking or special tests to check fabric sourcing and sustainability. Working closely with your knitwear manufacturer makes it easier to track fabric and make sure workers are treated fairly.

Note: Local fabric and microfactories can help you get knitwear faster and lower pollution. Making knitwear closer to home can cut supply chain emissions by up to 40%. Local fabric also means less waste and shorter wait times.

Flexible minimum order amounts are another big plus. They let you try new knitwear ideas and avoid having too much extra stock. This helps the planet and lets your brand grow slowly. Modular production and quick samples help you improve your knitwear and listen to customers.

If you follow these steps, you will find a knitwear manufacturer who shares your values. You get good knitwear, strong fabric sourcing, and a partner who helps your brand grow.

Finding the Right Fit for Knitwear

Aligning Values

You want your knitwear to show what your brand stands for. Look for a knitwear manufacturer who cares about the same things. They should care about the planet, fair work, and making good products. Many brands pick partners with certifications like GOTS, OEKO-TEX, or Fair Trade. These show they use safe fabric, treat workers well, and make eco-friendly knitwear. Building a long-term partnership helps you trust your manufacturer. It also keeps your fabric choices and knitwear quality the same.

Here are some ways brands make sure their values match with their knitwear manufacturer:

Choose manufacturers with strong certifications for fabric and knitwear.

Check samples and visit factories to see fabric quality and skill.

Ask for low minimum order amounts to try new knitwear ideas.

Work with more than one supplier to keep fabric and knitwear coming.

Ask about how they handle waste, energy, and where fabric comes from.

Brands like ARTEMIS DICERO and Bassike use natural fibers and local fabric. They make small batch knitwear and focus on fair work. They keep knitwear production close to home. This lowers pollution and helps workers make better knitwear.

Communication

Good communication helps your knitwear projects go well. You need clear updates about fabric, steps in production, and when knitwear will arrive. Many brands use digital tools like TrackIT to watch their knitwear orders. This tool lets you see fabric status and track knitwear progress. You can also use social media, email, or messaging apps to talk to your manufacturer.

Tip: Fast answers and honest updates help you trust your manufacturer. If they reply quickly and share fabric details, you know they care.

Checking in often helps you find problems early. You can give feedback on fabric, design, or skill before production ends. Brands that talk often with their manufacturer have fewer mistakes and better knitwear.

References

Before you pick a knitwear manufacturer, ask for references from other brands. Talking to other clients gives you real info about fabric quality, skill, and delivery times. You can ask about custom knitwear, how fabric problems were fixed, and if the knitwear matched the design.

Here’s a simple table of questions to ask references:

Question | Why It Matters |

|---|---|

Was the fabric quality consistent? | Makes sure your knitwear is good |

Did the knitwear match your design? | Checks if they pay attention to detail |

How was the communication? | Shows if you can trust their updates |

Were deadlines met? | Protects your brand’s reputation |

Would you work with them again? | Shows if they were happy overall |

Getting honest feedback helps you avoid problems. It helps you pick a knitwear manufacturer who cares about quality, fabric, and skill. This step protects your brand and helps you build a good name for your knitwear.

Picking the right small batch natural fiber knit manufacturer is important for your brand’s future. First, look for knitwear makers who share your values. Check if they have good experience and ask them for knitwear samples. Make sure they care about strong ethics. Talking clearly with them helps you get the knitwear you want. Some brands, like Toad&Co and Reformation, watch their knitwear’s sustainability and reputation over time. Here is what they do:

Brand | Knitwear Sustainability Practices | Knitwear Reputation & Impact Measures |

|---|---|---|

Toad&Co | Organic fibers, water recycling, small-batch | Public audits, resale programs, living wages |

Reformation | Deadstock knitwear, closed-loop production | Real-time footprint dashboard, take-back plans |

Always focus on quality, being green, and doing what is right. Start looking for your knitwear partner now and ask for help if you need it.

FAQ

How do I know if a manufacturer uses real natural fibers?

Ask for fiber certifications like GOTS or OEKO-TEX. You can also request fabric samples. Touch and feel the fabric. Real natural fibers feel soft and breathable. If you have doubts, ask for lab test results.

What is a typical minimum order quantity (MOQ) for small batch knitwear?

Most small batch manufacturers offer MOQs between 50 and 500 pieces. This lets you test new designs without a big investment. Always confirm the MOQ before you start your project.

Can I visit the factory before placing an order?

Yes, many manufacturers welcome visits. You can see their process, meet the team, and check working conditions. If you cannot visit in person, ask for a virtual tour or video call.

How long does it take to produce a small batch order?

Production time depends on your design and the factory’s schedule. Most small batch orders take 4 to 8 weeks. Ask your manufacturer for a timeline before you order.