Brora, a renowned Brora knitwear manufacturer, creates luxurious cashmere clothing by hand in Scotland. Most of the production takes place in the town of Hawick. This Brora knitwear manufacturer uses the finest Mongolian cashmere. Skilled artisans at historic Scottish mills contribute to crafting the garments. While some knitwear is sourced from the Czech Republic, the majority is made locally. Brora values British craftsmanship and supports preserving jobs in the UK.

As a dedicated Brora knitwear manufacturer, the company works closely with traditional mills to ensure every cashmere piece meets the highest quality standards.

Key Takeaways

Brora makes most of its cashmere knitwear by hand in Hawick, Scotland. Skilled workers use old methods to make the clothes.

The company uses only the best grade A cashmere from Mongolian goats. Workers carefully take out rough hairs to keep the softest fibers.

Brora mixes old handcrafting skills with new machines. This helps every piece stay high quality, soft, and last a long time.

Most of the clothes are made in Scotland. This helps local jobs and keeps textile traditions alive. Some knitwear is made in the Czech Republic.

Brora cares about the planet. They work with good suppliers, help Mongolian herders, and recycle fabric to cut down on waste.

Brora Knitwear Manufacturer

Manufacturing Steps

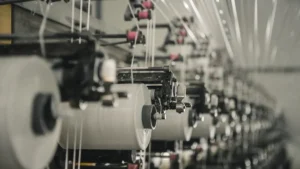

The brora knitwear manufacturer uses more than 50 steps to make each piece. It all starts with getting raw cashmere from goats in Mongolia. Every spring, workers gently comb or pluck the goats by hand. This helps them collect the soft underfleece. The fleece comes in dirty and tangled, mixed with rough hairs. Workers must remove the coarse hairs from the soft cashmere. This step takes away about half of the fiber, but it keeps only the best material.

Next, the brora knitwear manufacturer sorts the cashmere by color. White fibers are saved for lighter colors. Some cashmere stays its natural color, but some gets dyed now. After sorting, the fibers are spun into yarn. In Scotland, both old-fashioned hand skills and new machines are used. Hand-operated machines and hand-knitters do important jobs and finishing touches. Each piece goes through about 40 steps, many done by hand. Quality checks happen all the time to make sure the finish is soft and fancy.

Every step is done with care so brora clothes are always top quality.

Main Steps in the Manufacturing Process:

Shearing or combing goats for raw cashmere

Grading and sorting the wool

Shipping wool for processing and dyeing

Scouring and washing to remove impurities

Extracting lanolin as a by-product

Carding to separate and straighten fibers

Choosing spinning method: worsted or woollen

Combing for worsted yarns

Preparing combed top for spinning

Dyeing, often at the combing stage

Materials

Brora picks only the best materials for its clothes. The brora knitwear manufacturer gets all its cashmere from goats in Mongolia. This cashmere is grade A, which means it is soft, warm, and strong. Workers take out all the rough guard hairs so the fabric feels smooth. The mill works with Johnstons of Elgin, a supplier known for being fair and caring for the planet.

Aspect | Details |

|---|---|

Supplier | Johnstons of Elgin, a key supplier to Brora |

Certification | Member of Sustainable Fibre Alliance (SFA), adheres to SFA Cashmere Standard |

SFA Standard | Includes animal welfare (five freedoms), grassland management, and herder criteria |

Certification Impact | 80 tons of raw fiber produced with SFA certification; traded at 10% above market price |

Consumer Transparency | No consumer-facing labeling for SFA-certified cashmere yet; hangtag planned soon |

Brora’s Role | Ensures traceability and ethical sourcing through Johnstons of Elgin’s SFA adherence |

This table shows how brora makes sure its cashmere is tracked and sourced the right way. The company cares about animal welfare and using land wisely. Brora wants to give customers more information in the future.

Handcrafting

Handcrafting is still very important for the brora knitwear manufacturer. Skilled workers and hand-knitters work in Scottish mills, mostly in Hawick. They use old methods that have been taught for many years. These workers shape, join, and finish each item by hand. Their skill makes every piece special and soft.

The brora knitwear manufacturer pays close attention to every detail. Workers check each item before it leaves the mill. This focus on quality makes sure every brora knitwear piece is the best. By mixing old handcrafting with new machines, brora makes knitwear that is comfy, stylish, and lasts a long time.

Brora Factory Locations

Hawick, Scotland

Hawick is in the Scottish Borders. It is the main place for Brora’s production. The town has made knitwear for hundreds of years. In 1771, James Hardie brought the stocking frame to Hawick. This started a new tradition that grew fast. By the 1800s, Hawick had more knitting frames than any other town in Scotland. The town’s population got bigger as the industry grew. Hawick became known as the cashmere capital of the world. Many famous knitwear brands started here, like Pringle of Scotland and Johnstons of Elgin.

Brora’s cashmere comes from the Johnston of Elgin mill in Hawick. Workers use tight knitting and hand linking to make each piece strong and smooth. They wash the wool with care, so the fabric gets softer and fits better over time. These skills have been taught for many years. The soft water from the River Teviot helps make luxury knitwear. Hawick is known for its design and quality. This keeps its good name, even when other places try to compete.

Hawick’s long history and skilled workers make it special for Brora’s knitwear.

Other Scottish Mills

Brora mainly makes its products at the Hawick mill. No other Scottish mills make Brora’s cashmere. Focusing on one place helps keep quality high and supports local jobs. The mill uses both old and new ways to make each item. This helps save Scotland’s textile traditions.

The Scottish Borders are also known for tweed. Many towns here have made tweed for a long time. These mills use local wool and old skills to make strong, patterned cloth. Tweed is still popular for jackets, hats, and other clothes. The mills in this region, including Hawick, help keep these traditions going.

The Scottish Borders are important for both cashmere and tweed.

Tweed mills use special patterns and weaving.

Local work helps the community and keeps old skills alive.

Czech Republic

Brora also makes some knitwear in the Czech Republic. This country has skilled workers and a long history with textiles. The Czech factories use modern machines and check quality carefully. Brora picks these places for some products to meet demand and keep standards high. The company still watches the process closely to make sure every item is right.

The Czech Republic’s part in Brora’s work shows how the brand mixes old ways and new needs. Most items come from Scotland, but Czech factories help Brora offer more products. This helps Brora stay strong in the market and keep its focus on quality.

Brora’s focus on making things in Scotland helps the textile industry. The company uses old skills and local things, like the soft water from the River Teviot. This focus on quality and tradition helps keep Scotland’s textile history alive.

Brora Craftsmanship

Local Production

Brora cares a lot about making things in the UK. The company works with Scottish knitters who use old ways to make clothes. These knitters use their hands and also some machines. They make each cashmere piece with care. Brora wants to make good clothes and not waste anything. This helps keep old skills alive and helps people in the area.

Brora Development Trust started the Otter’s Couch. This group lets over 40 local people earn money by making crafts. It also has a Visitor Information Point. This place helps people meet and learn about old crafts.

Brora also helps herders in Inner Mongolia. They pay these farmers early when winters are hard. This helps the farmers and keeps the cashmere coming. The company uses old clothes and leftover fabric to make new things. Workers fix, paint, and change these materials to cut down on waste. This helps the planet and makes Brora a leader in luxury fashion.

Heritage

Brora’s history is important for its place in luxury knitwear. The company began in 1993 to update Scottish cashmere but keep it special. Brora dyes and knits its cashmere in Hawick. The soft water from the River Teviot makes the fabric feel nice. Skills are taught from parents to children. This makes sure every piece is made well.

Brora’s story goes back to the Highland Clearances. The distillery gave jobs to local people.

The company uses local water and coal to help the town.

Brora keeps old buildings and machines working. This shows they care about old ways and new ideas.

Special collections and fixing old things help keep Brora’s story strong.

Brora’s focus on local work, old skills, and caring for the earth makes people trust them. The company’s story and careful work make it a top name in luxury knitwear.

Brora makes knitwear by hand in Scotland and the Czech Republic. Skilled workers use old methods and good materials. Making things locally gives people jobs and helps the town grow.

Brora is a luxury brand with high quality, but some other brands talk more about their history and how they make things.

People can enjoy knowing each piece has a story and skill. Brora helps keep old ways and local traditions going.

FAQ

Where does Brora source its cashmere?

Brora gets its cashmere from Mongolia. Workers gently take the soft underfleece from goats by hand. The company picks only the best, grade A fibers for its knitwear.

Are all Brora products made in Scotland?

Most Brora knitwear is made in Hawick, Scotland. Some pieces are made in the Czech Republic. Brora keeps most work in Scotland to help local jobs and skills.

How does Brora ensure quality in its knitwear?

Skilled workers check each item many times as it is made. Brora uses both handwork and machines to make sure every piece is top quality.

What makes Brora knitwear sustainable?

Brora works with suppliers who care for animals. The company uses leftover fabric to cut down on waste. Brora also helps herders in Mongolia when winters are tough.

Can customers visit Brora’s factories?

Brora does not let the public tour its factories. Customers can learn about how things are made on the website and at special events.