Everlane Knitwear is a leader in fashion. They care about being open and fair. The brand works with trusted factories. They make sure workers are treated well. Everlane Knitwear uses good materials that help the planet. They want to lower harm to the environment. People can trust Everlane Knitwear to be honest and make good products.

Key Takeaways

Everlane Knitwear is very open. They share real costs and supply chain facts. This helps customers trust them a lot. The brand uses organic and recycled materials. This helps the environment and makes products safer. Everlane picks factories with care. They check them often to make sure workers get fair pay. They also check for safe work and eco-friendly actions. Each sweater is made by skilled workers. It goes through many quality checks. This makes the knitwear comfy and strong. Everlane is honest and fair. This makes customers loyal. People like ethical fashion and smart shopping.

Transparency Approach

Radical Transparency

Everlane Knitwear is different because it is very open. The company thinks customers should know how things are made and what they cost. To do this, Everlane Knitwear has some clear rules:

They show the cost for each product, like materials, labor, transport, and profit. Their markup is about 2x, which is much less than the usual 8-10x.

They keep only a small amount of products in stock to avoid discounts and keep prices steady.

They do not use normal store markups or discounts, so prices stay the same.

They sell only a few types of products and make small changes to basics like sweaters.

They use waiting lists to guess how many people want something and to get feedback for new ideas.

These actions help Everlane Knitwear earn trust and show a new way to be open in fashion.

Why It Matters

Being open in fashion is important. It changes how brands work and how people shop. When companies like Everlane Knitwear share supply chain details, they help stop bad things like unfair work and hurting the planet.

Digital Product Passports (DPP) show where a product comes from and how it was made.

Certifications like Fair Trade, GOTS, and B Corp prove brands care about workers and the planet.

Technology like blockchain and outside checks help people trust that brands do the right thing.

Laws like the UK Modern Slavery Act and EU rules make brands share supply chain facts and help make better rules.

Studies say most shoppers want brands to be honest about where things come from and how workers are treated.

Being open helps brands make strong bonds with customers and keeps them safe from scandals. It also lets companies find and fix problems early, which helps them do well for a long time.

Everlane Knitwear Materials

Material Types

Everlane Knitwear uses many good fibers in its clothes. The brand picks organic cotton for lots of sweaters and cardigans. Organic cotton grows without bad chemicals. This keeps the soil and farmers safe. Recycled wool and cashmere are in many of their collections. These fibers come from old clothes or leftover fabric. Using recycled materials helps cut down on waste and saves resources. The brand does not use new plastics in its knitwear. When needed, it uses recycled polyester instead. This choice helps lower the need for making new plastic.

Note: Picking organic and recycled fibers helps the planet and keeps people healthy.

Sourcing Practices

The Everlane Knitwear team works with trusted suppliers. They go to farms and factories to check how things are made. The team likes suppliers who follow strict rules for the environment and workers. They look for certifications like GOTS for organic cotton and Global Recycled Standard for recycled fibers. These show the materials are made in a good way. The company also tracks where each material goes. This makes sure every step matches the brand’s values.

A normal sourcing process has these steps:

Picking certified farms for organic cotton.

Working with mills that recycle wool and cashmere.

Checking suppliers for fair work and safe places.

Testing materials to make sure they last and feel good.

Sustainability Efforts

Everlane Knitwear is a leader in making fashion better for the earth. The brand wants to stop using new plastics in its supply chain. It uses recycled polyester instead of new plastic fibers. The company also watches how much water it uses. Organic cotton farming uses less water than regular cotton. The brand works with suppliers who clean and reuse water. These systems help save water and stop pollution.

The company checks how each material affects the environment. It picks fibers that make less carbon. The team also tries to cut waste at every step. By using recycled materials and saving resources, Everlane Knitwear helps the planet.

Material | Source Type | Environmental Benefit |

|---|---|---|

Organic Cotton | Plant-based | Less water, no toxic chemicals |

Recycled Wool | Animal-based | Reduces landfill waste |

Recycled Cashmere | Animal-based | Saves resources, less energy |

Recycled Polyester | Synthetic | Cuts virgin plastic use |

Tip: People can help the planet by picking products made from recycled and organic materials.

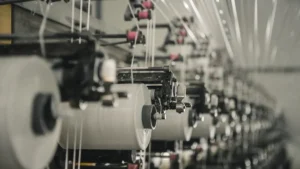

Factory Network

Global Locations

Everlane works with many factories in different countries. These factories are in Asia, Italy, the United States, Spain, and Peru. Each place has its own special skills and ways of making things. Factories in Italy are very good at making fine knitwear. Factories in Asia can make a lot of clothes and use new machines. In Peru, workers use local materials and old methods. The United States and Spain also have their own strong ways of making clothes. By working with factories in many places, Everlane can make many kinds of knitwear.

Note: Everlane uses the best skills and materials from each country by working with many factories.

Selection Process

Everlane picks its factories very carefully. First, they look for safe places with good working conditions. They care about having good relationships with factory owners. They check if workers get fair pay and work normal hours. They also want factories to care about the earth. Some factories, like one in Vietnam, recycle almost all their water and use waste to make building stuff. Everlane likes factories that try to help the planet.

The team also wants factories to be honest and open. They want to know how things are done. If a factory needs help, Everlane will help them get better. This way, both Everlane and the factories can grow and do better together.

Audit Standards

Everlane checks its factories often to make sure they follow the rules. They do big checks every year and smaller checks every few months. These checks look at pay, safety, and how the factory treats the earth. The team looks at papers, talks to workers, and walks around the factory. If a factory does not do things right, Everlane helps them fix it.

The checks also see how factories use water and energy. Factories must show they recycle water, make less trash, and use clean energy if they can. Everlane shares the results of these checks with everyone. This helps people trust Everlane and shows they care about doing the right thing.

Audit Focus Area | Frequency | Key Checks |

|---|---|---|

Worker Safety | Quarterly | Equipment, emergency exits |

Fair Wages | Annual | Payroll, wage records |

Environmental Impact | Annual | Water recycling, waste management |

Working Hours | Quarterly | Shift logs, overtime records |

Tip: Checking factories often helps keep workers safe and treated fairly.

Production Steps

Knitwear Manufacturing

A sweater starts with raw cashmere. Workers in Mongolia wash the fibers to get rid of dirt and oils. After washing, they pack the cashmere tightly. Then, they send it to a place near Ningbo, China. Skilled workers keep the cashmere safe and get it ready for the next step. They dye the fibers in many different colors. Each batch gets checked to make sure it looks right.

After dyeing, the cashmere goes to a spinning factory. Machines there pull, comb, and split the fibers. This mixes the colors and makes thin yarns. The factory keeps the air at the right temperature and humidity. This helps the yarn stay strong and soft. Workers watch the machines and look for any problems in the yarn.

The yarn then goes to knitting factories. Machines knit panels for each sweater part, like arms, front, and back. Skilled workers use special machines to join these panels. This job needs careful hands and good eyes. After joining, the sweaters go to the finishing area.

Quality Control

Quality control is very important in making sweaters. Workers check each sweater after it is put together. They look for loose threads, bad stitches, or color mistakes. If they find something wrong, they fix it before moving on.

After checking, workers press the sweaters to take out wrinkles and make them look nice. Each sweater is packed carefully to keep it safe during shipping. The team checks the sweaters one last time before they leave the factory.

Note: Careful work at every step helps make sure each sweater is comfy, strong, and looks good.

Cost Breakdown

Transparent Pricing

Everlane wants customers to know what each sweater part costs. The company splits the price into simple pieces. These are things like materials, labor, and other costs. Other costs can be transport or hardware. This helps people see where their money goes.

Here is a normal cost breakdown for a knitwear item:

Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

Materials | Cashmere fabric, about 2 yards at $18-$20 per yard (grade A quality) | ~$40 |

Labor | Factory wages in China, including extra costs and how hard it is to make | $13.53 |

Additional Costs | Hardware, transportation, duties | Remaining balance |

Some sweaters use other materials or are made in other places. For example, another breakdown shows:

Component | Cost (USD) |

|---|---|

Materials | $4.28 |

Labor | $4.65 |

Transport | $0.20 |

Everlane also tells people about the factory. They share who owns it and how the sweater is made. This makes customers trust the company more. People can see most of the price is for good materials and fair pay.

Customers like knowing the real cost of each item. This helps them choose better and feel good about what they buy.

Comparison to Other Brands

Most fashion brands do not show how they set prices. Some brands add a lot to the price, so people pay much more than it costs to make. Everlane does things differently. The company keeps prices fair and explains every cost.

Everlane’s prices show the real cost of materials and labor.

The brand tries to be affordable and fair, which is not common in fashion.

For example, the Merino Ski Sweater costs $135 and people like its quality and look.

Most brands care about profit, but Everlane cares about being open and fair.

Shoppers like knowing how their clothes are made. They trust brands that share this kind of information.

Labor Practices

Fair Wages

Everlane thinks all workers should get fair pay. The company checks pay records at every factory. They look at pay and compare it to local laws. They also check if pay meets living wage standards. If a factory pays too little, Everlane asks them to fix it. The team looks at pay raises every year. They want workers to have enough money for food, homes, and other needs.

Fair pay lets workers help their families and have better lives.

Worker Welfare

Worker welfare is very important to Everlane. The company checks safety, health, and comfort in each factory. Every place must have clean water and safe tools. There must be emergency exits too. Workers learn about safety rules. Factories must give breaks and not too much overtime.

A normal welfare checklist has:

Medical care for workers

Clean bathrooms and places to rest

Fire drills and safety plans

Help for pregnant workers

A safe and healthy job makes workers feel cared for and respected.

Continuous Improvement

Everlane helps factories get better every year. The team visits factories many times. They talk to workers and managers. If they find problems, they make a plan to fix them. Factories must solve these problems by a set time. Everlane also gives training on new safety and labor rules.

Improvement Area | Action Taken | Result |

|---|---|---|

Safety | New equipment checks | Fewer accidents |

Wages | Annual pay reviews | Higher worker income |

Training | Safety workshops | Better awareness |

When things keep getting better, workers see real changes, not just words.

Everlane Knitwear Impact

Product Quality

Everlane Knitwear is known for making quality sweaters. The company uses Grade-A cashmere and other top fibers. These sweaters feel soft and last a long time. Many people say the sweaters keep their shape and comfort. This is true even after wearing them many times. The brand checks important things to keep quality high:

How long the sweaters last

How soft the fabric feels

If pilling happens under the arms or sides

If the shape stays the same after washing

Most people think Everlane Knitwear is worth the price. Many sweaters stay soft and keep their shape, showing they are strong. Some wool-blend sweaters may pill faster in places that rub a lot. Sometimes, customers talk about sizing problems or small defects. In general, the knitwear is good and can be trusted, but it is not always luxury. The brand keeps getting better by listening to reviews and making changes.

Note: Checking quality and listening to customers helps Everlane Knitwear keep high standards.

Consumer Trust

Everlane is open about how it makes its products. This helps customers trust the company. The company shares how much things cost and what factories are like. They also talk about how workers are treated. People who care about fair and green fashion like this honesty. Everlane sells straight to customers, so prices are lower.

Fair sourcing and good labor rules bring in caring shoppers.

Classic styles and clear messages help people stay loyal.

Talking with the community and being honest makes relationships stronger.

Customers like knowing how their clothes are made. Many people buy from Everlane Knitwear again because they trust the brand. They also like the company’s promise to do the right thing. This trust makes people come back and stay loyal for a long time.

Tip: Being open and caring about ethics helps Everlane Knitwear grow and have a good name.

A supply chain that is open and fair helps everyone:

Workers get paid fairly, work in safe places, and can learn new skills.

Shoppers trust brands more when they see clear prices and know where things come from, so picking what to buy is easier.

The earth is helped when companies use resources wisely and make things in ways that do not harm nature.

Being open and choosing good sources makes people trust brands and makes products better. When you support brands that care about these things, you help make things better for everyone. Try to buy smart, look for good quality, and ask brands to do the right thing.

FAQ

How does Everlane ensure ethical labor in its factories?

Everlane goes to each factory many times. The team checks if workers get fair pay and safe work. They look at how long people work each day. Audits help them find problems. They also talk to workers to learn more. If something is wrong, Everlane helps the factory fix it.

What materials does Everlane use in its knitwear?

Everlane picks organic cotton, recycled wool, recycled cashmere, and recycled polyester. These choices help cut down on waste. They also help keep the earth safe.

Picking recycled and organic fibers helps make the planet healthier.

Where are Everlane’s knitwear factories located?

Factories are in Asia, Italy, the United States, Spain, and Peru. Each place has special skills and ways to make knitwear.

Country | Specialty |

|---|---|

Italy | Fine knitwear |

Peru | Local materials |

Modern machinery |

How does Everlane keep its prices transparent?

Everlane shows the cost for each part of a product. They tell you how much materials, labor, and transport cost. Customers can see where their money goes.

Materials

Labor

Transport

This way, shoppers can trust the company.