Fashion buyers who want rib knit fabric can find good suppliers in top regions.

Metric | Value |

|---|---|

Circular Knit Fabric Market Size (2024) | |

Forecast CAGR | 6.1% |

Leading Region | Asia Pacific |

Ribbed knit fabric is popular in 2024. It is known for its stretch, feel, and use in tight clothes. Buyers should look at stretch, bounce back, and weight of the fabric. Good suppliers and green methods, like safe dyeing and organic cotton, are important now. More people want this fabric, especially for summer and tight clothes.

Key Takeaways

Rib knit fabric can stretch a lot. It keeps its shape well. It is good for tight clothes like cuffs, collars, and waistbands.

Buyers should pick trusted suppliers. These suppliers need eco-friendly certifications. This helps buyers get safe and high-quality rib knit fabric. It also makes sure the fabric is good for the planet.

Custom orders let brands choose colors, materials, and designs. This helps them make special rib knit products. These products match their own style.

New green materials and smart technology make rib knit fabric better. They help with comfort and durability. They also lower harm to the environment.

Buyers should check fabric samples and supplier quality. This helps them avoid problems. It also helps them build strong, long partnerships.

Rib Knit Fabric Overview

Structure and Properties

Rib knit fabric is special because of how it is made. It has lines called wales that go up and down on both sides. This stops the fabric from curling and helps it stay flat when cut. The way the wales are set up gives rib knit fabric its straight lines and lets it stretch a lot from side to side. It can stretch twice as wide as it is, so it works well for tight clothes like cuffs, collars, and waistbands. Rib knit fabric is stretchy and snaps back into shape. This helps clothes keep their shape and not get loose, even after many washes and wears.

How rib knit cotton fabric feels depends on the yarn and how it is finished. Modal microfibers make rib knits that are lighter, thinner, and puffier than regular modal. These fabrics soak up more sweat and feel soft on your skin, but they might not let air through as well. Rib knit fabric is tough and does not wear out fast, especially if made with air-jet-spun yarns. These yarns make the fabric look smooth and help it last longer. The weight of the fabric matters too. Light 1×1 ribs are good for tight spots like cuffs. Heavy 2×2 or 3×3 ribs are better for sweaters and jackets.

Note: Rib knit fabric’s stretch and bounce back help clothes last longer and make people happy. Ribbed hems and necklines keep their shape and look nice, even after lots of washes.

Weight Category | Approximate GSM | Characteristics | Suitable Fashion Applications |

|---|---|---|---|

Heavy Rib Knit | Thick, strong, structured, durable | Sweaters, cardigans, outerwear, winter clothing | |

Medium-weight Rib Knit | ~190 gsm | Balanced stretch and comfort, medium thickness | Summer clothes, ribbed details on cuffs and neckbands |

Light Rib Knit | Light weight | Very stretchy, flexible, soft | Snug-fitting areas like cuffs, collars, activewear |

Manufacturing Basics

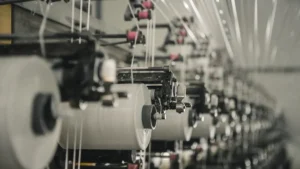

Factories make rib knit fabric with special circular knitting machines. These machines use two kinds of needles to make the ribbed pattern. The needles are set up in a certain way to make 1×1 or 2×2 ribs. Yarn goes through the needles, which switch between knit and purl loops. The machines must run at the right speed and keep the yarn tight. If not, the ribs can look uneven or get messed up.

Checking the fabric is very important. Workers and machines look for problems and make sure the fabric is stretchy, strong, and looks good. After knitting, the fabric is washed, dried, and sometimes treated to make it better. The way the yarn is spun, like ring or open-end spinning, changes how strong and soft the rib knit is. All these steps help make rib knit fabric that is good for today’s fashion buyers.

Rib Knit vs Jersey

Key Differences

Rib knit fabric and jersey fabric are not the same. Rib knit fabric is made with knit and purl stitches. This makes straight lines, called ribs, on both sides. Jersey fabric has only one kind of stitch. The front feels smooth, but the back feels a little rough.

The table below shows how they are different:

Feature | Rib Knit Fabric | Jersey Fabric |

|---|---|---|

Structure | Vertical ribs on both sides | Smooth front, textured back |

Stretchability | Very high, stretches up to twice its width | Lower stretch, thinner and softer |

Elastic Recovery | Keeps shape after many washes and stretches | Moderate elasticity, less recovery |

Thickness & Texture | Thicker, more textured | Lightweight, smooth on one side |

Rib knit cotton fabric is very stretchy and snaps back well. It keeps its shape even after many washes. Jersey fabric is lighter and feels softer. It is good for clothes that do not need to stretch much or keep their shape.

Tip: Use rib knit cuff material for places that must stay tight, like cuffs and waistbands.

Best Uses

Fashion buyers pick rib knit or jersey fabric for different clothes. Rib knit fabric is best for tight and stretchy clothes. Jersey fabric is better for loose and light clothes.

Rib Knit Fabric Type | Key Properties | Suitable Garments |

|---|---|---|

Soft, breathable, good stretch and recovery | Cuffs, waistbands, t-shirts, sweaters, dresses | |

Polyester Rib Knit | Durable, wrinkle-resistant, moisture-wicking | Activewear, sportswear, snug fit garments |

Rayon Rib Knit | Lightweight, silky, good drape | Dresses, skirts, flowy garments |

Warm, cozy, moisture-wicking | Sweaters, cardigans, cold-weather wear | |

Bamboo Rib Knit | Eco-friendly, soft, antibacterial | Activewear, sensitive skin garments |

Jersey fabric is great for t-shirts, light dresses, and underwear. Ribbed knit fabric gives shape and stretch to tight tops, rib knit cuff material, and sports clothes. Buyers use knit ribbing fabric for parts that need to last, like necklines and hems.

Sourcing Rib Knit Fabric

Global Suppliers

Fashion buyers want good rib knit fabric. They look for places with big textile industries. Asia-Pacific is the top area, and China is the leader. Many big companies in China make ribbed knit fabric and cotton rib knit fabric. Other important places are Pakistan, Mexico, Uzbekistan, Bulgaria, Russia, and the United States. Latin America is growing fast in this market. Europe and North America are still strong in the industry.

The table below shows some top global suppliers and what they do best:

Company Name | Headquarters | Specialty / Notes |

|---|---|---|

Zhejiang Baodi Textile Co., Ltd. | China | High-quality knitted fabrics using cotton, polyester, wool |

Shaoxing Global Chemical Fiber Co., Ltd. | China | Large supplier of knitting and weaving fabrics including synthetic blends |

Zhejiang Yinlan Import and Export Co., Ltd. | China | Focus on R&D, produces polyester, cotton, rayon fabrics |

Shaoxing County Changfa Knitting Co., Ltd. | China | Produces polyester, Tencel, bamboo fabrics with strong R&D |

Zhejiang Golden Knitting Co., Ltd. | China | Rib, interlock, jersey fabrics; well-established reputation |

Shanghai Changmin Textile Co., Ltd. | China | Organic cotton, bamboo, Modal fabrics with R&D focus |

Madiyo Dekna | Russia | Rib knits, interlocks, jerseys; quality and affordability |

E.Miroglio | Bulgaria | Circular knitted fabrics and yarns |

Hamrick Mills | USA | Woven and knit fabrics including cotton blends |

Tip: Buyers can also look at companies like Jiangsu Sunshine Co., Ltd. and Shandong Ruyi Technology Group Co., Ltd. for big orders.

Quality and Sustainability

Quality and being eco-friendly are very important when picking a supplier for fabric rib knit. Buyers should check if suppliers have special certificates. These certificates show the supplier meets high standards. Some common certificates are:

GOTS (Global Organic Textile Standard): Checks for organic material and safe processing.

GRS (Global Recycled Standard): Makes sure recycled materials are used and safety rules are followed.

OEKO-TEX: Proves the fabric is safe from harmful chemicals.

FSC (Forest Stewardship Council): Supports good forest care for raw materials.

BCI (Better Cotton Initiative): Helps make cotton supply chains more fair.

These certificates help buyers know that rib knit cotton fabric and rib knit cuff material are good and safe for the planet. Many suppliers now sell ribbed knit fabric made from organic cotton or recycled polyester. This is because more people want eco-friendly fabric.

Note: Always ask for certificates and test reports before making big orders.

Supply Chain Strategies

Good supply chain management helps buyers get rib knit fabric on time and at a good price. Buyers should use these tips:

Pick suppliers based on how much you need and if you want custom fabric. Mills, converters, and wholesalers each have different benefits.

Work with certified suppliers to make sure you get good and fair products.

Watch the supply chain to make sure deliveries are on time and quality stays high.

Check suppliers for quality, price, and their background. Try to save money but also get reliable fabric.

Do checks and audits to make sure suppliers follow the rules.

Use services to find trusted distributors.

Use supplier networks and experts to get cheaper raw materials.

Keep checking how suppliers do and plan shipping for easy buying.

Negotiation is also important for getting good deals. Buyers should:

Say exactly what product, amount, certificates, and delivery time they want.

Find and list suppliers using websites and contacts.

Check what suppliers can do by looking at their work and doing audits.

Look at all the terms, like price, payment, quality, and shipping.

Try small orders first to check quality and trust.

Build long-term partnerships with clear talks and fair deals.

Tip: Buying a lot at once and having good relationships with suppliers can help buyers get better prices and save on shipping.

Applications in Fashion

Apparel and Accessories

Designers use rib knit fabric in lots of clothes and accessories. The fabric stretches and goes back to its shape. This makes it great for parts that get pulled a lot. People use it for neckbands, sleeve cuffs, and waistbands in men’s and women’s clothes. It is also in dresses, t-shirts, pajamas, leggings, and tights. Pullovers, nursing dresses, and zip inseam pajamas use it too. Pocket bindings and footie cuffs often have rib knit fabric. Ribbed knit fabric gives clothes structure and stretch. It helps clothes fit close but not lose their shape. Hats, scarves, and gloves also use this fabric because it is soft and flexible.

Summer and Fitted Styles

Rib knit cotton fabric is good for summer and tight clothes. The fabric lets air through and stretches, so it feels nice in hot weather. Many brands use knit ribbing fabric for tank tops, fitted tees, and light dresses. The fabric fits the body but lets you move easily. Cotton rib knit fabric soaks up sweat and feels soft on your skin. This makes it a favorite for activewear and loungewear in summer.

Tip: Pick rib knit cuff material for places that must stay tight, like cuffs and waistbands, especially in fitted summer clothes.

Market Trends

Fashion brands like rib knit fabric because it can be used in many ways. Designers use digital printing to put bright pictures and patterns on ribbed knit fabric. This makes clothes stand out. The fabric fits many body shapes, so brands can sell to more people. Shoppers want comfort, style, and easy care. Rib knit cotton fabric gives all these things in everyday clothes, athleisure, and special fashion pieces.

Knitting Pattern Segment | Market Share in 2023 | Consumer Preference Indication |

|---|---|---|

Plain Knit | About 35% | Biggest market share, most liked knitting pattern |

Ribbed Knit | Big market share, shows strong customer liking |

Sustainability is important in fashion now. Many brands use recycled fibers and earth-friendly ways to make fabric rib knit. The market will keep growing, especially for athleisure and streetwear.

OEM and Custom Orders

MOQ and Customization

Fashion buyers often want to know about minimum order quantities (MOQ) and how they can change rib knit fabric when buying from OEM suppliers. Suppliers set MOQ so they can make fabric in a way that saves money and time. The table below shows what some top suppliers ask for:

Supplier | MOQ (Minimum Order Quantity) | Notes |

|---|---|---|

Alibaba Supplier | For custom rib knit fabric, color, and width | |

Starke Textiles | 1000 yards per color per style | Normal MOQ; extra fee for smaller orders |

Starke Textiles | 1500 yards per color | Some knit fabrics; extra fee for small orders |

Buyers can ask for smaller orders, but they might have to pay more. Customization lets brands make special products that fit their ideas. These choices include:

Picking fabric material like cotton, polyester, blends, or fancy yarns

Custom colors using color samples or Pantone numbers

Changing sizes for different places

Printing and embroidery, like silk screen, digital, or 3D printing

Adding logos and trademarks for the brand

Custom packaging to match the brand’s look

Flexible order amounts, sometimes as low as 50 pieces for samples

Making samples to check designs before big orders

Tip: Brands should get samples first to check quality and color before buying a lot.

Yarn and Color Options

OEM suppliers have many yarn types and color matching services for ribbed knit fabric. Polyester spandex blends are popular, with mixes like 92/08, 95/05, and 97/03. These blends stretch and last a long time. Makers also make rib textures like 11, 22, 42, 73, and 18*4. These cover both light and heavy fabric needs.

Rayon spandex rib fabrics, usually 92% rayon and 8% spandex, come in lots of colors. These are yarn-dyed, and buyers can pick the shade they want. OEM suppliers help match colors by custom dyeing and picking yarn. Multi-color and yarn-dyed ways help brands get the look they want.

Buyers can also pick from:

100% cotton rib knit fabric for softness and air flow

Blends for better performance or to be more eco-friendly

Yarn-dyed or piece-dyed for even color

Custom finishes, like anti-wrinkle or quick-dry

Note: Matching colors is very important for brands. Brands should give Pantone numbers or color samples for best results.

OEM Process

The OEM process for rib knit cotton fabric has clear steps. This helps buyers get what they want and keeps quality high. The steps are:

Buyer asks about the product

Factory checks how long it will take and if they have space

Factory gives a price

Buyer confirms and sends a purchase order

Payment is arranged

Factory books fabric and extras

Factory makes a sample for the buyer to check

Factory gets and checks materials

Factory has a meeting to confirm details

Factory makes patterns for big orders

Factory sets up the line and does a test cut

Factory cuts, numbers, and sorts the fabric

Factory checks the cut panels for quality

Sewing and putting pieces together

Checking and finishing at tables

Final check and quality control

Delivery to the buyer

During these steps, merchandisers watch progress, check quality, and handle shipping. Private labeling lets brands add their own labels, trims, and packaging. This helps brands look special and stand out.

Private labeling lets brands pick design, materials, and style.

It helps brands make more money by cutting license costs.

Brands can follow trends faster with shorter wait times.

Flexible MOQs and payment plans help both new and big brands.

Custom labels and packaging make customers like the brand more.

Callout: Private labeling and OEM services help brands make more products, keep quality high, and show off their own style.

Innovations and Trends

New Materials

Rib knit fabric is changing because of new, green materials. TENCEL Lyocell fibers now give good stretch and comfort. This makes them a top pick for eco-friendly ribbed knit fabric. Regenerated nylon like ECONYL uses trash from oceans and landfills. It turns this waste into strong yarns. These new materials help the planet and keep the fabric stretchy and tough. Top makers use green ways from getting yarn to shipping fabric. This helps rib knit cotton fabric work better and be kinder to nature. Waterless dyeing is now common. It uses up to 90% less water than old ways. These new ideas make the fabric better and more responsible.

Technology in Rib Knit Fabric

Technology has changed how factories make fabric rib knit. New machines use smart needle systems. They make rib knit fabrics that are softer and let air through. Electronic controls and robots help make more fabric faster. They also keep the quality the same. Factories now use double-sided rib knitting heads. This means both sides of the fabric are made at once. It saves time and makes even rib knit cuff material. Computers help designers make cool patterns with less waste. 3D knitting lets factories make clothes with almost no seams. This makes clothes comfy and cuts down on fabric joints. These new tools also help use recycled yarns and fibers that break down. This makes rib knit fabric better for the earth.

Consumer Preferences

People now want rib knit fabric that is comfy, stylish, and green. Many like ribbed knit fabric with special textures and 3D looks. Surveys show shoppers will pay more for green choices. Cotton rib knit fabric made from organic or recycled fibers is popular. Designers use bright colors, mixed fibers, and special finishes to make cool clothes. More people want high-quality, eco-friendly knit ribbing fabric. Brands that let buyers add their own labels and designs get more customers. Buyers want products that match what they care about and like.

Note: The rib knit fabric market will keep growing. New materials, technology, and what people want will shape the future of fashion textiles.

Sustainability and Reliability

Eco-Friendly Choices

Fashion buyers want eco-friendly knit ribbing fabric now. Top mills use organic cotton. This cotton needs less water and fewer chemicals. Recycled polyester comes from plastic bottles. It saves energy and cuts down on pollution. Many brands pick TENCEL™. This fiber is soft and made from trees that grow back. Some suppliers have X4ZOL™-J fiber. This is a recyclable TPU. It can take the place of spandex and uses less energy to make.

Factories use new ways to finish fabric. These include treatments that stop germs, block UV rays, and resist water or stains. These finishes help the fabric work better and stay green. Automation and digital tools help save materials and cut waste. Green finishing methods lower harm to nature but keep ribbed knit fabric strong.

Tip: Buyers should ask if suppliers use organic, recycled, or new fibers. They should also ask about green treatments.

Supplier Evaluation

Good suppliers help brands keep quality and trust. Buyers need to check fabric quality with special tests. These tests look at seam strength and color staying power. Labels and tags must follow rules and stay on during making. Checking supplier papers on inspection and quality control helps keep standards the same.

Looking at the fabric helps find flaws, color problems, or mistakes. Many buyers use the 4-point system. This system gives points for defects by size and how bad they are. It gives a fair score for rib knit fabric quality. Buyers should also check softness, strength, air flow, stretch, and bounce back with ASTM tests.

A checklist for checking suppliers includes:

Look at how the fabric is made and what fibers are used.

Check care tips and if the fabric lasts a long time.

Ask for samples to make sure everything is right before big orders.

Note: Doing regular checks and talking clearly with suppliers helps brands avoid mistakes and build good partnerships.

Fashion buyers need to remember some key things when picking rib knit fabric:

Rib knit fabric feels soft and stretches well. It is strong, so it works for everyday clothes, work outfits, and sportswear.

Printed ribbed knit fabric comes in many looks and fibers. You can find cotton rib knit fabric and bamboo blends.

Picking trusted suppliers helps you get good quality, fair prices, and helpful service.

Buyers should ask for fabric samples, read care tips, and check for eco-friendly certifications on knit ribbing fabric.

Buyers can make their brands bigger by working with OEM partners, choosing green materials, and learning about new trends. This is a good time to look at how you find fabric and plan products for long-term success.

FAQ

What makes rib knit fabric different from other knits?

Rib knit fabric is made with knit and purl stitches. This gives it lines that go up and down on both sides. It can stretch more than jersey fabric. Rib knit fabric also keeps its shape better. Designers use ribbed knit fabric for cuffs, collars, and tight clothes.

How can buyers check the quality of rib knit cotton fabric?

Buyers should ask for fabric samples from suppliers. They should look for certifications like OEKO-TEX or GOTS. Buyers can test how much the fabric stretches and if it goes back to normal. They should also check if the fabric feels soft. Good suppliers give test reports and care tips for cotton rib knit fabric.

Is rib knit cuff material suitable for activewear?

Yes, rib knit cuff material is great for activewear. It stretches well and goes back to its shape. The fabric stays tight when you move. Many brands use knit ribbing fabric for cuffs, waistbands, and necklines in activewear. It helps clothes fit snug and feel comfy.

Can brands customize colors and patterns on ribbed knit fabric?

Brands can pick special colors using Pantone codes or fabric samples. OEM suppliers can print, dye, or add embroidery to the fabric. This helps brands make ribbed knit fabric that matches their style.

What sustainable options exist for fabric rib knit sourcing?

Organic cotton rib knit fabric

Recycled polyester blends

TENCEL™ and bamboo fibers

Buyers should ask suppliers about eco-friendly certificates and green ways to make knit ribbing fabric.