Craftsmanship shows the real worth of premium knit dresses worldwide. Skilled workers use old methods and new tools to make great dresses. Each dress uses luxury fibers and shows careful work. Strict checks make sure every dress is high quality. Buyers like these dresses because they are comfy, strong, and look nice. More buyers now care about sustainability and fair sourcing.

Key Takeaways

Premium knit dresses stand out in the fashion market thanks to their use of luxury fibers like cashmere and Merino wool, which offer exceptional softness, strength, and comfort across all seasons. Behind each dress is a careful blend of traditional craftsmanship and modern machine knitting—skilled artisans incorporate intricate detailing and shaping techniques that enhance durability and style. From fiber selection to final inspection, premium knitwear undergoes strict quality control at every stage, reducing material waste and ensuring long-lasting wear. To confirm authenticity, buyers can look for certified labels, QR codes, and brand-issued certificates, and are advised to purchase only from trusted retailers to avoid counterfeits. Sustainability is also a core value in premium knitwear production: top brands now use eco-friendly materials like organic wool and apply fair labor practices throughout their supply chains. This holistic approach not only supports environmental responsibility but also reflects a growing demand for ethical, high-quality fashion.

Premium Knit Dresses: Global Appeal

Market Trends

More people want premium knit dresses all over the world. This is because people care about fashion, comfort, and the planet. New studies show some important trends:

The global knitwear market was worth $894.06 billion in 2024. It may reach $2,481.20 billion by 2033. The market is growing fast at 12.07% each year.

Shoppers now like eco-friendly and high-quality fabrics. They often pick organic cotton and wool.

New technology like 3D knitting helps make dresses faster. It also lets brands make special designs for buyers.

Classic styles like cable knit and Fair Isle are more popular now. People want clothes that last and look good.

Online shopping helps brands sell to more people everywhere.

Different places have their own reasons for buying knit dresses:

Region | Growth Driver | Demand Characteristics |

|---|---|---|

Asia Pacific | More cities and higher incomes | People follow Western styles and more can buy nice clothes |

North America | People care about fashion and need clothes for seasons | They spend a lot and want clothes that are useful and green |

Europe | Famous brands and skilled makers | Many want designer and luxury knitwear |

Latin America | More stores and a bigger middle class | People want stylish and affordable knitwear |

Middle East & Africa | More cities and love for luxury fashion | People want light knitwear for hot weather |

Big brands and eco-friendly labels keep making new styles. They change their collections to match what buyers want each season.

Versatility and Wearability

Premium knit dresses are very flexible for people everywhere. You can wear them in many places and in different weather. The fabric you choose matters a lot:

Material | Key Properties | Climate Suitability | Versatility Benefit |

|---|---|---|---|

Wool | Warm and keeps sweat away | Good for cold places | Keeps you warm and comfy in winter |

Cotton | Lets air in and feels soft | Good for hot places | Keeps you cool and comfy in summer |

Acrylic | Light and not expensive | Good for any weather | Feels soft and can be used in many ways |

Blends | Mix of good things | Works in many climates | Gives warmth, lasts long, and stretches |

Light knitwear means you can wear these dresses all year. You do not have to wait for a certain season. People can pick premium knit dresses for fancy or casual events. They are comfy and stylish. Young people in cities like to wear them to work, for fun, or at parties. This makes premium knit dresses more popular around the world.

Materials and Craftsmanship

Luxury Fibers

Luxury fibers make premium knit dresses different from regular clothes. Makers pick the best materials like cashmere, Merino wool, and Sea Island cotton. These fibers are soft, warm, and last a long time. Cashmere comes from goats and feels light but keeps you warm. Merino wool is known for letting air in and being comfy, so buyers like it a lot. Sea Island cotton is smooth and strong.

Good fibers do more than make dresses comfy. They also help dresses last longer and keep their shape after many washes.

A new survey shows why these fibers matter:

Feature | Statistic | Importance |

|---|---|---|

Preference for Merino wool | Valued for breathability and warmth | |

Preference for chunky knits | 80% prefer chunky knits | Chosen for added warmth in colder settings |

Comfort with acrylic yarn | 90% cite superior comfort | Essential for sustained wearability |

Makers sometimes mix these luxury fibers with new yarns like recycled polyester. This mix makes dresses soft, pretty, and better for the planet. Using top yarns means each dress is comfy, strong, and eco-friendly. Picking the right fibers fits what more people want: stylish, high-quality, and green knitwear.

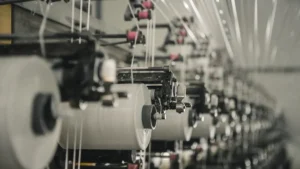

Artisanal Techniques

Skilled workers make every premium knit dress with care. They use old hand-knitting and new digital machines. In Asia, handlooms work with smart machines. In Europe, old looms mix with digital tools. The Americas use both old and new ways.

Many families teach knitting skills to their kids. Workers add trims and details by hand, so each dress is special.

Here’s how these methods make dresses better:

Aspect | Supporting Evidence Summary |

|---|---|

Regional Practices | Handlooms in Asia, digital precision in Europe, automation in the Americas |

Mathematical Modeling | Digital controls balance pattern complexity and production efficiency |

Sustainability Metrics | Traditional knowledge with modern production reduces energy use by 15–25% and lowers waste |

Workforce Development | Training merges hand skills with machine operation |

Hybrid Technologies | Handloom artistry combines with digital precision for better design and quality |

Kiton, a top brand, uses very fine fibers measured in microns. Their workers handle these rare fibers with care, using both old and new ways. This makes dresses that feel soft, stretch well, and last a long time.

Hand knitting keeps skills alive that machines can’t copy.

Skilled workers join dress parts for a smooth finish.

Artisans add trims and fancy details, not just basic stitches.

The human touch makes sure each dress is top quality.

Premium Knit Dresses show this mix of luxury fibers and skilled work. The result is a dress that feels special, looks nice, and can be worn every day.

Quality Assurance

Multi-Stage Control

Quality assurance uses many steps to check each knit dress. Each step finds problems early and keeps things running well. Factories use both people and smart machines to make sure every dress is great.

Raw Material Inspection

Workers look at fabrics for any problems. They check color, strength, and if it will shrink. This stops bad fabric from being used.In-Line Inspections

Inspectors check dresses during cutting, sewing, and washing. They use samples to find mistakes fast and stop them from spreading.Pattern and Cutting Precision

Teams make sure patterns match the rules. They cut fabric carefully so dresses fit and look good.Sewing Operation Monitoring

Supervisors watch stitches and seams. They check if everything lines up and is strong.Final Garment Inspection

Before shipping, inspectors look for sewing mistakes and fabric flaws. They check if the dress fits right in all sizes.

Tip: Finding mistakes early saves time and money. It also makes customers happy.

Factories use charts to count how many dresses have problems each day. These charts help managers see issues quickly. If there are too many mistakes, teams fix them fast. Most of the time, about 4% of dresses have problems. Sometimes, this number is as low as 0.94% or as high as 8.5%. Keeping numbers low means less waste and better quality.

Smart machines do simple checks by themselves. This lets workers focus on harder problems. Automation also means less fixing and less waste. This saves money and helps factories work better. Brands use these systems to make buyers trust them and keep a good name.

Here is a table showing important quality control numbers:

Metric | Description | Role in Quality Control |

|---|---|---|

First Pass Yield (FPY) | Percent of dresses that pass the first time | Shows if the process works well right away |

Scrap Rate | How much fabric is thrown away | Lower numbers mean better use of materials |

Supplier Defect Rate | How many problems come from the fabric supplier | Makes sure fabric is good |

Cost of Quality | Money spent on checks and fixing mistakes | Helps balance spending and quality |

Return Material Authorizations (RMAs) | Number of dresses sent back for problems | Shows if customers are happy and if dresses are consistent |

Teams use special tools like charts and lists to find the main causes of mistakes. By fixing these big problems, factories make better dresses, save money, and make buyers happier.

Identifying Authenticity

Authenticity is important for buyers who want real quality. Many brands use special ways to show their dresses are real.

Unique Labels and Tags

Brands put labels with numbers or QR codes on dresses. Buyers can scan these to check if the dress is real.Certificates of Authenticity

Some brands give papers that show where the fiber came from, when it was made, and who made it.Material Testing

Labs test the fibers to see if they match the label. For example, they check if cashmere is really cashmere.Brand-Specific Features

Brands use special stitches or trims that are hard to copy. These help buyers know the dress is real.

Note: Buyers should buy from trusted stores or the brand’s own shops. This helps avoid fake dresses.

Buyers and stores can also look for good signs, like even stitches and smooth seams. Real dresses feel soft and last after many washes. Brands that check quality well earn trust and keep customers coming back.

Sustainability in Premium Knit Dresses

Eco-Friendly Materials

Sustainability is changing how knitwear is made. Top brands now pick eco-friendly materials because more people want them. They use organic cotton, recycled fibers, and yarns that break down, like bamboo, hemp, and wool. These choices help the planet and make sure materials are gathered the right way.

The knitwear market is getting bigger as more people want clothes that are good for the earth. Brands such as Patagonia, Stella McCartney, PANGAIA, and Eileen Fisher lead the way. They use things like recycled polyester, organic cotton, and even seaweed fiber. Some brands let customers return old clothes or buy dresses that can break down, which helps the environment.

Using waterless dyeing and natural dyes saves water and cuts down on chemicals. Closed-loop factories clean and reuse water and chemicals. Solar power helps lower pollution from making clothes.

Certifications help buyers know the process is safe. GOTS, OEKO-TEX Standard 100, bluesign®, and Cradle to Cradle Certified™ show that the clothes are made safely. These rules make sure the fabric does not have bad chemicals and that factories use resources carefully.

New ideas also help make knitwear greener:

3D knitting and 3D printing cut down on wasted fabric and let people order special items.

AI helps brands guess what people want and makes the supply chain better, so less is wasted.

Blockchain lets buyers check if brands are honest about being ethical.

New materials like lab-grown leather and bio-fabricated textiles are better for the earth.

Ethical Production

Ethical production is about more than just green materials. Companies now make sure workers are treated fairly and work in safe places. They help people work from home or in their communities by giving training and fair pay. This helps local workers and makes communities stronger.

Many brands keep good records and follow tough rules from groups like the World Fair Trade Organization. They pay fair wages, give bonuses, and offer things like childcare and rides to work. Companies do not allow child labor or forced labor and follow the law. They also support women and make sure everyone is treated equally.

Zero-waste factories use all leftover fabric to make new things, so nothing is thrown away.

Being open and honest is important. Regular checks and sharing costs help build trust. These steps make sure every dress helps both people and the planet.

Premium Knit Dresses are special because of their luxury fibers, careful craftsmanship, and green practices. Buyers should pay attention to three main things.

Make sure the dress is real and the brand is trusted

Check that quality is watched at every step

Look for dresses made in fair and earth-friendly ways

To get the best dress, buyers can talk to skilled suppliers or ask for samples before they choose.

FAQ

What makes a knit dress “premium”?

Premium knit dresses use top fibers like cashmere or Merino wool. Skilled workers make each dress with care. Brands check every step for quality. These dresses feel softer and last longer than normal ones.

How can buyers check if a knit dress is authentic?

Buyers should look for special labels, QR codes, or brand certificates. Trusted brands often have unique stitching or trims.

Tip: Always buy from official stores or trusted sellers.

Are premium knit dresses suitable for all seasons?

Yes. Makers use different fibers for different weather. Cotton is good for summer. Wool keeps you warm in winter. Many blends give comfort and style all year.

Why do brands focus on sustainability in knitwear?

Sustainability helps keep the planet safe. Brands use eco-friendly fibers and safe dyes. They also make sure workers are treated fairly. Buyers now want products that help people and the earth.

What quality checks do premium knit dresses go through?

Factories check materials, watch sewing, and inspect the finished dress.

Workers look for fabric problems.

Machines test seams and fit.

Brands track returns to make quality better.