The knitwear spectrum is getting bigger as leaders work on every part of knitwear to fit world trends. New knitting technologies help this growth. The global knitting machines market was worth USD 4.9 billion in 2023. It is growing fast because of automation and new ideas.

Segment/Region | Market Value (2023) | CAGR (2024-2032) | Market Share (2023) | Key Impact/Notes |

|---|---|---|---|---|

Global Knitting Machines Market | USD 4.9 billion | >5.4% | N/A | Growth comes from new technology, automation, and more need for clothes and textiles. |

Weft Knitting Machines Segment | USD 3.4 billion | 5.5% | N/A | Seamless knitting tech cuts fabric waste and labor costs. It also helps meet the need for custom items. |

Fully Automatic Machines | N/A | 5.4% | ~72% revenue share | Shows a move to automation for better speed, accuracy, and mass production. |

U.S. Market | USD 1.2 billion | 5.3% | 83% (North America) | The U.S. uses advanced knitting tech a lot. Growth is helped by automated making and textiles. |

Asia Pacific (China) | N/A | ~5.6% | 32% (China) | China leads in making textiles. The market is growing a lot with new knitting technologies. |

Sustainable knitwear is becoming more popular as people want eco-friendly materials and better ways to make clothes. The knitwear industry is changing by using smart manufacturing, making less waste, and focusing on good quality. This promise keeps the knitwear spectrum leading in fashion innovation.

Key Takeaways

The knitwear market is growing quickly because of new machines and more people wanting comfy, earth-friendly clothes. – Fashion brands use computers and social media to find trends fast. They make knitwear that matches what people want everywhere. – New knitting ways like 3D knitting help make less waste. They also help make cool, good-fitting clothes faster and better. – Being eco-friendly is very important now. Brands use recycled fibers and organic stuff to help the earth and give people what they want. – Careful checks with AI and skilled workers make sure every knitted dress looks nice and lasts a long time. This keeps customers happy.

Knitwear Spectrum and Global Trends

Trend Analysis

The knitwear spectrum is getting bigger as fashion changes. People want new styles and brands pay attention to what buyers like. They look at online stores, social media, and what influencers say. This helps them know which styles and materials are popular everywhere. Brands use this information to make more types of knitted dresses for different places.

Note: Online shopping lets brands sell to people all over the world. It also helps them get feedback from customers right away.

When we look at the market, we see some important things:

Trend/Statistic | Description |

|---|---|

Online stores help brands reach more people and give them more choices. | |

Sustainability & Eco-Friendly | More people want clothes made with organic fibers and less energy. |

Smart Fabrics Integration | Some knitwear has sensors that can check your health or keep you warm. |

Asia-Pacific Market Share | This area has the biggest share because of China, India, and people spending more money. |

Rising Disposable Incomes | People in growing countries have more money to spend on knitwear. |

Athleisure & Casual Wear Popularity | People like comfy clothes they can wear anywhere, so knitwear is more popular. |

Social Media & Influencers | What people see online makes them want new knitwear trends. |

Fashion companies use smart ways to guess what people will want next. They use computers to look at lots of data. This helps them make new knitwear that fits what people like and what is new in technology. For example, more people want athleisure and casual wear, so brands make more comfy knitwear. They also watch for changes in seasons and prices of materials to plan when to make and sell new clothes.

The knitwear market is expected to grow by about 12.86% each year because people want comfy and eco-friendly clothes.

Online shopping makes it easier for brands to try new styles and be more eco-friendly.

New technology like 3D knitting helps brands waste less and make special designs.

More people want knitwear that anyone can wear and that works for many things, so brands focus on these styles.

Brands watch for changes in seasons and problems with getting materials to plan when to make new collections.

Market Adaptation

Fashion leaders change fast when trends change. They use digital tools and new technology to keep up. They watch social media and what influencers do to see what people like. This helps them make new knitwear that matches what people want right now.

Tip: Brands that use digital tools and talk to customers can change faster and make better products.

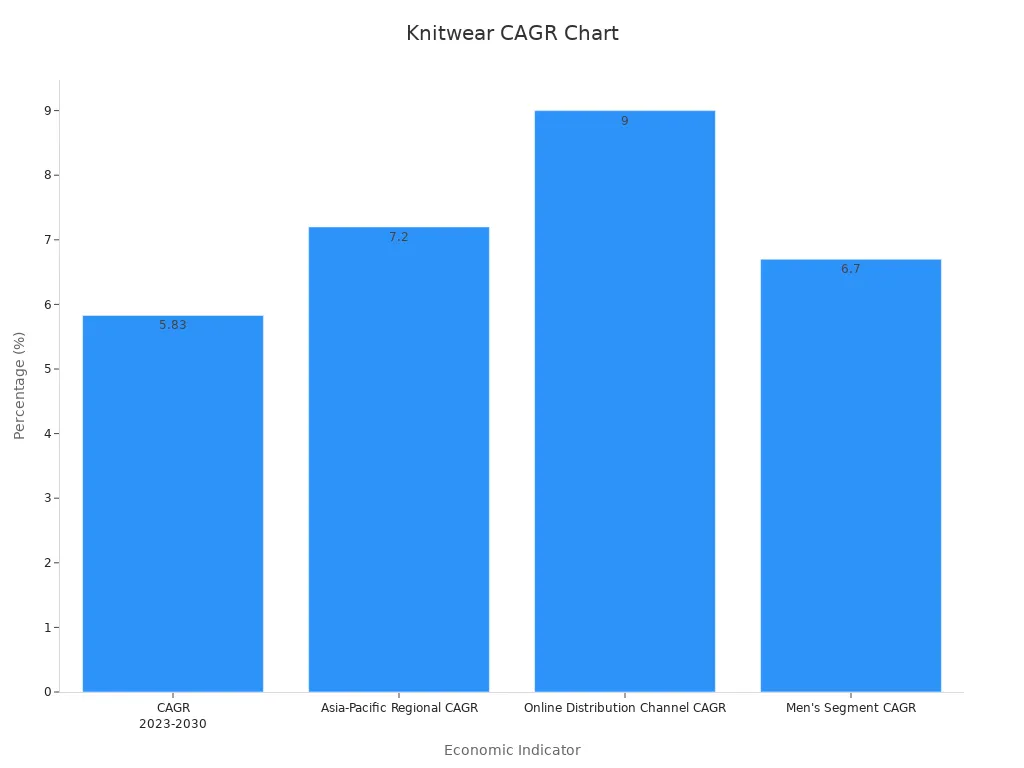

Brands use numbers like sales and profit to see how well they are doing in different places. These numbers show if they are reaching new customers and making more types of knitwear. For example, Asia-Pacific is the biggest in knitwear spectrum because they make a lot in China and India. North America is growing fast because people there care about fashion and like clothes for different seasons.

Asia-Pacific is the leader in knitwear spectrum because they make and ship a lot of clothes.

North America does well because people spend more and there are many stores.

Online shopping and selling straight to customers help brands grow in both places.

60% of people like comfy clothes for daily life, so knitwear for sports and relaxing is in demand.

Social media and influencers help people learn about new knitwear trends.

Fashion brands that change with global trends keep the knitwear spectrum interesting and up to date. Brands that use technology, digital ads, and data can give customers what they want and stay ahead of others.

Design and Innovation in Fashion

Style Development

Design teams help shape what fashion looks like next. They notice when people work from home or care more about health. Then, they make knitted dresses that fit these new ways of living. These teams want every dress to feel good and look nice. They make sure their clothes work for casual, semi-formal, and fancy events. More people want knitwear that is easy to care for and can be used in many ways. Teams use digital tools and ai to spot trends and design faster. They try new things like yarn dyeing, digital decorations, and eco-friendly materials to keep up with fast changes in fashion.

Designers need to change fast when new trends appear. They use ai and digital tools to get feedback and update their designs quickly.

Fashion numbers show people want knitwear that is both comfy and stylish. New ideas like cable knits, ribbed patterns, and seamless styles are popular with many people. The knitwear market was worth USD 907.60 billion in 2024. This shows that new ideas and good design are very important.

Technology Integration

Technology helps knitwear change and get better. Flat knitting and 3D knitting let makers create cool shapes and use less material. This means less waste and less work. The table below shows how these methods help make better products and save time:

Technology/Technique | Quantitative Influence on Product Design | Impact on Product Design and Manufacturing Efficiency |

|---|---|---|

Flat Knitting (Shaping Techniques) | Changing stitch number and length; making wider or smaller parts | Makes textiles that fit well, wastes less, and allows 3D shapes |

Partial Knitting & Stitch Length Variation | Stopping needles, changing stitch length in spots | Makes many 3D shapes, helps clothes fit better, and adds cool designs |

ITA 3D-Knit Technology | 3D fabrics, fast work, sewing-like looks | Makes 3D fabric quickly, uses less material, and works better |

Material and Waste Reduction | Makes shapes close to final size, no waste | Cuts down on waste, saves work and time, and helps the planet |

The fashion world also uses ai, digital models, virtual reality, and augmented reality. These tools help designers make virtual fitting rooms and make supply chains faster. Big companies now control over 60% of the 3D knitting market. Synthetic fibers bring in USD 398.5 million, and Asia Pacific has a 36% share of the market.

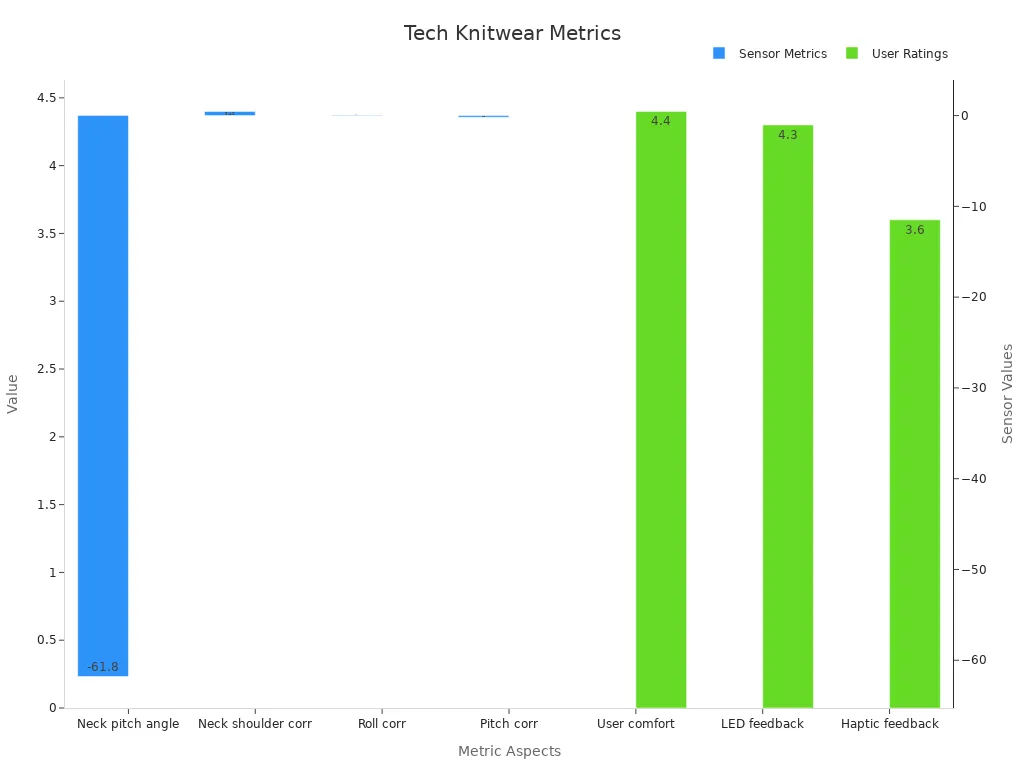

Technical knitwear now has smart textiles with sensors inside. These give both useful and stylish benefits. People rate comfort at 4.4 out of 5, so technology makes clothes feel and look better. Using ai, digital tools, virtual reality, and augmented reality helps fashion keep growing. It lets brands mix good looks with high performance.

Materials and Sustainability

Yarn Selection

Yarn choice is important for every knitted dress. Designers pick from cotton, viscose, cashmere, and blends. They do this to fit what people want in different places. The Knitting Yarn Market report says each yarn type has special benefits. People care about how strong, stretchy, soft, and dry the yarn is. Blended yarns mix good things from each fiber. This makes them a top pick for clothes and home items. Makers use tests to check how strong and absorbent the yarn is. They change how much of each fiber they use to make better fabric.

Studies show people like yarn blends that are good for the planet. Many want cashmere mixed with organic cotton or recycled fibers. About half of buyers will pay more for green or custom products. Certifications like Responsible Wool Standard and Global Organic Textile Standard help people trust brands. These show a brand cares about the planet. More brands using new blends have grown their market share by 15%. This shows how important it is to pick yarns that are good for the earth.

Eco-Friendly Practices

Eco-friendly ways are shaping the future of knitwear. Brands use recycled polyester from bottles, organic cotton, and natural dyes. This helps lower harm to the planet. The eco-friendly textiles market was worth USD 7.15 billion in 2022. It could reach almost double by 2030. Big brands like Patagonia, Nike, and Stella McCartney use recycled fibers. Rules and new tech help these changes happen. AI helps brands waste less by 31%. This makes making clothes faster and better.

Evidence Aspect | Details |

|---|---|

Market Valuation (2022) | USD 7.15 billion globally for eco-friendly textiles market |

Projected Market Size (2030) | USD 13.93 billion with CAGR of 10% |

Key Eco-Friendly Material | Recycled polyester (from recycled plastic bottles) reducing plastic waste |

Leading Brands Using Recycled Fibers | Patagonia, Nike, Adidas, Levi Strauss & Co., H&M, Stella McCartney |

Government & Tech Drivers | Regulations and technological advances promoting sustainable textile manufacturing |

Recent Product Launches | H&M’s organic cotton and recycled denim line (2022), Levi’s eco-friendly materials plan (2022), Stella McCartney’s recycled knitwear (2021) |

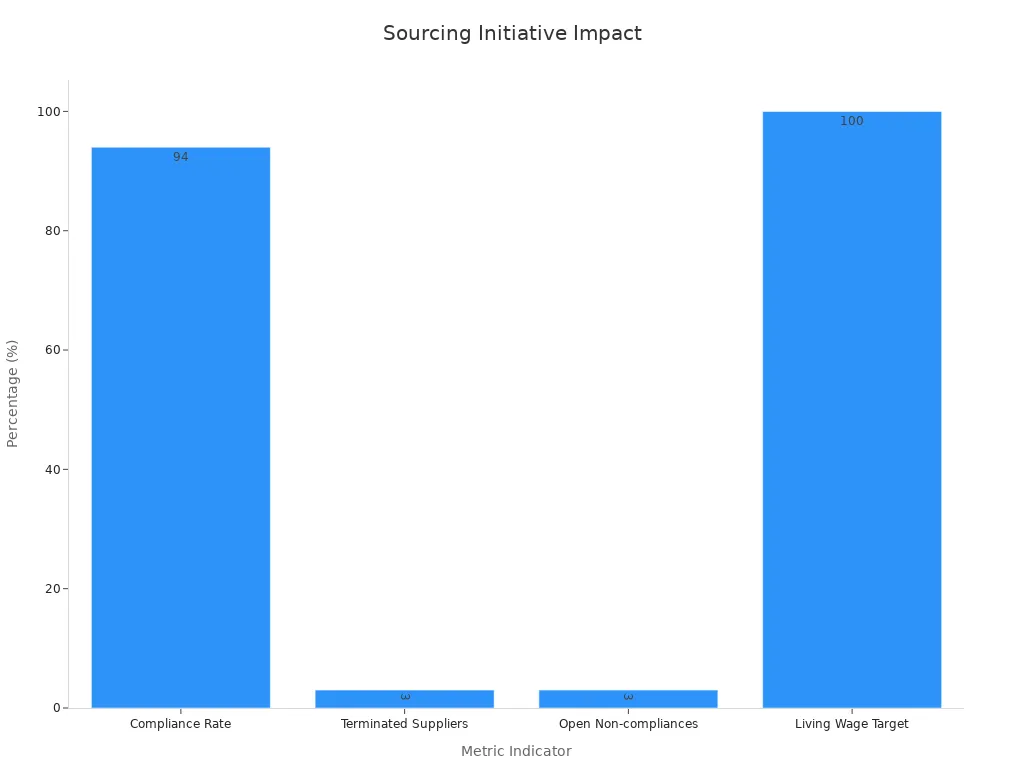

Getting materials the right way keeps the supply chain strong. In 2024, 546 supplier sites had audits. 94% followed social and environmental rules. Brands work with groups like Fair Wage Network for fair pay and safe jobs. Problems do not happen again after fixing them. These steps help brands be more green and meet what all shoppers want.

Note: Sustainability is now very important in fashion. Brands that use green materials and get them the right way are leaders in both new ideas and luxury.

Production and Quality Control

Manufacturing Process

Making knitted dresses follows a careful process. This helps every dress meet high standards for people everywhere. Teams start by planning for quality. They set clear goals for each step. Before knitting, they check yarn and trims to make sure they are good. New machines and ai help keep things the same from the start.

Teams plan for quality and set goals.

They check yarn, trims, and other parts.

During making, they watch for mistakes in cutting and sewing.

At the end, they check size, stitches, and how the dress looks.

They keep learning and write down what they do.

While making dresses, machines with cameras and ai look for problems fast. This helps stop bad products and keeps work moving well. Managers check many times, looking at things like zippers and sizes. Technology helps track each step. Only the best dresses go to stores.

Stage | Description |

|---|---|

Preparation | Get the yarn table ready with tools and good lights. |

Yarn Sample Selection | Pick yarn samples from each batch in a random way. |

Visual Inspection | Look at yarn for knots, slubs, or thick spots with a magnifier. |

Physical Inspection | Test yarn for strength, twist, and size as needed. |

Defect Classification | Sort problems by how bad they are using a chart. |

Documentation | Write down details like batch, date, inspector, and notes. |

Decision Making | Decide if the yarn is good enough to use. |

Disposition | Put bad yarn aside for fixing or throwing away. |

Reporting | Share the inspection report with the team and suppliers. |

Quality Assurance

Quality assurance uses both tech and skilled workers. Checks during making use ai and cameras to watch every step. Numbers like First Pass Yield and Scrap Rate help measure how well things are made. These numbers show how many dresses pass the first check and how much material is wasted.

Metric | Description | How it Illustrates Consistency of Quality During Production |

|---|---|---|

First Pass Yield (FPY) | Shows how many items pass without fixing or waste. | Tells if the process is good and if most items are right the first time. |

Scrap Rate | Shows how much material is thrown away during making. | Less waste means better control and better quality. |

Supplier Defect Rate | Shows how many materials from suppliers are not good enough. | Good suppliers help make sure the final product is always good. |

Cost of Quality | Adds up all costs for checking and fixing quality. | Helps find ways to save money and keep quality high. |

Return Material Authorizations (RMAs) | Counts how many items are sent back because of problems. | Shows if customers are happy and if the quality is steady. |

Teams use feedback from around the world to get better. They use data and ai to find patterns and improve how they work. Setting goals and checking progress helps everyone do their best. Comparing with other brands helps stay ahead in stores.

Checking results during making helps keep quality high:

Fiber checks make sure there are no problems.

Yarn tests look for evenness and strength.

Stitch checks keep size and tightness the same.

Pattern checks make sure designs line up right.

Finishing checks look at trimming, washing, and other steps.

Size checks see if the dress shrinks or stretches.

Shape checks see if the dress keeps its form.

Color checks see if the color stays after washing or rubbing.

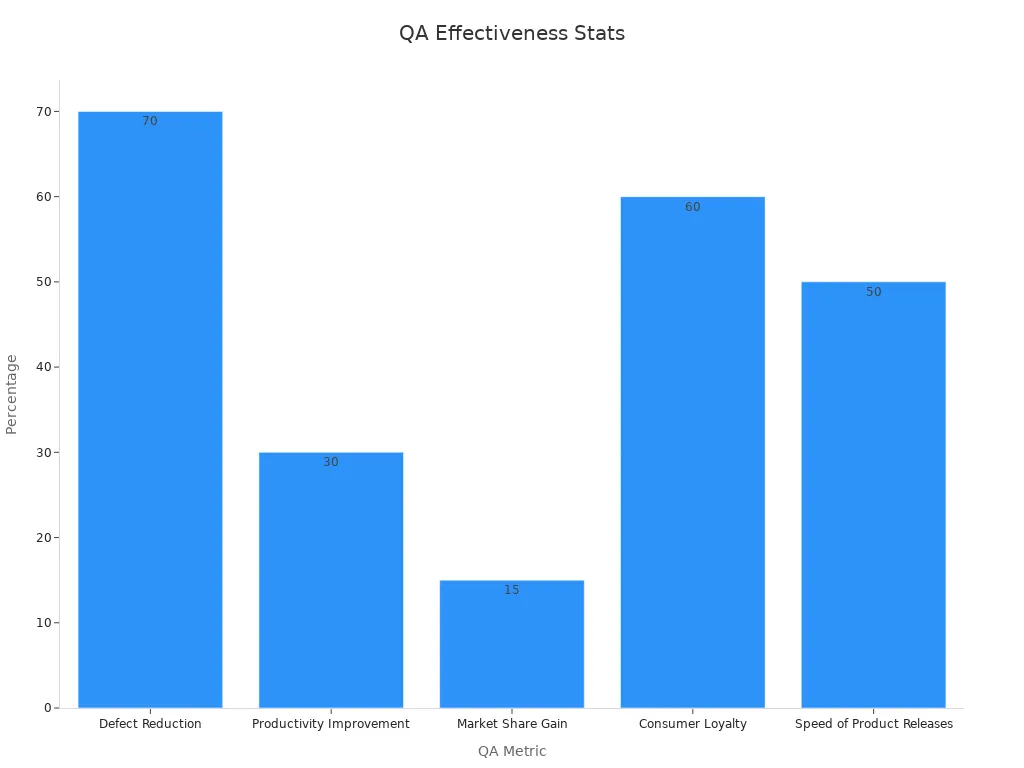

Numbers show these steps work well. Brands can cut defects by 70% and work faster by 30%. Market share can go up by 15%. If quality stays high, 60% of people will buy again. Using automatic tools helps get products to stores 50% faster.

Engineering in knitwear helps brands keep up with fashion trends. It also helps them meet different market needs. The table below shows how new ideas help the market grow:

Statistic / Insight | Details |

|---|---|

Global knitwear market size (2021) | |

Projected market size (2030) | USD 1605.69 billion |

CAGR (2024-2030) | 12.10% |

Natural knitwear segment market share (2021) | 50-60% |

Expected CAGR of natural knitwear segment | Highest among segments due to sustainability and eco-friendly innovations |

Key technological advancements | New fibers, finishing technologies (e.g., LYCRA naturalFX) |

Contribution of knitwear features | Breathability, wrinkle resistance, moisture wicking driving demand, especially in sportswear |

Sportswear market growth drivers | Increased sporting activities, internet usage, and demand for knitted sportswear (t-shirts, pants, socks) |

Online distribution impact | E-commerce innovations accelerating global knitwear market growth |

Regional import data (Europe) | €21.8 billion in 2019, up from €17 billion in 2014; 5.1% annual growth in imports |

Textile company managers see that better quality often means more eco-friendly and faster work. Many brands use new materials and digital tools. Some brands still need to try things like 3D simulation. Social media helps brands find out what is popular. It also helps them talk to customers and show new ideas. Social media spreads news about green ways and better quality. It will keep helping knitwear change with new fashion trends.

FAQ

What types of yarns do brands use for knitted dresses?

Designers pick cotton, viscose, cashmere, and blends. Each yarn has something special. Cotton is soft and lets air through. Viscose makes the dress shiny. Cashmere keeps you warm. Blends mix good things for comfort and strength.

How does technology improve knitwear production?

New machines like flat and 3D knitting help make exact shapes. AI and cameras find mistakes early. These tools help waste less and work faster. Brands can send out great dresses more quickly.

Why is sustainability important in knitwear?

Sustainability helps protect nature. Brands use recycled fibers and organic stuff. They follow strict rules for getting materials. These steps cut down on waste and pollution. People like green products, so brands use more eco-friendly ways.

How do brands ensure quality in every dress?

Teams check yarn, stitches, and patterns at every step. Machines and workers look for mistakes. Brands use data to watch quality. They fix problems fast. This keeps dresses nice and customers happy.

What global trends shape the knitwear spectrum?

Fashion leaders watch social media and online shops. They see what people buy and like. Trends like comfy clothes and eco-friendly styles guide new looks. Brands change fast to keep up.

2 thoughts on “Expanding the Knitwear Spectrum: How We Engineer Every Kind of Knitted Dress to Match Global Market Trends”

Pingback: Knitwear That Performs: How We Design and Produce Function-First Knitted Dresses for Global Brands

Pingback: Top Supplier Making Stockholm’s Knitwear Dreams Real