You notice a big change when a professional factory makes designer knitwear. Teams use special machines to make each dress fast and right. Quality inspectors look for problems like pilling or seams that are not even. This way, you get knitwear that is made very well. This method keeps mistakes low, even when they make more dresses. Designers and engineers team up to mix fashion, style, and comfort. Luxury knitwear is possible because of careful checks and smart design. When you wear knit dresses from a professional factory, you feel real skill and new fashion.

Key Takeaways

Professional factories work together and use smart tools. They design and make knit dresses that fit well. The dresses also look nice. Picking the best yarn is important. Testing materials helps make strong and comfy knitwear. This also makes the clothes better for the planet. New knitting machines help make dresses faster. 3D and 4D knitting technology makes seamless and cool dresses. These machines also help use less material. Skilled workers put the dresses together and finish them. This makes sure each dress feels soft. The dresses fit well and last a long time. Careful quality checks find problems early. These checks keep every dress the same and high quality.

Professional Factory Approach

Design Collaboration

When you walk into a professional factory, you see people working together. Designers, engineers, and skilled workers meet to talk about new ideas. Each person has something special to share. The designer shows pictures and drawings of new knitwear styles. Engineers explain how to make these ideas real using special machines. Skilled workers talk about how to make the dresses fit well and look nice.

Note: When designers and factory teams work together, knitwear gets better. Using digital tools like Shima Seiki’s APEX FIZ, you can make virtual samples. You can show these samples to everyone on the team. This helps people see the design and know how to make it. You make fewer mistakes and save time. You also use less material, which is good for the planet.

A professional factory likes when people talk openly. The team checks every part, like what yarn to use and how to change the design. They talk about adding cool patterns or special textures to the dresses. This way, every piece of knitwear looks good, fits well, and feels comfortable.

A tech pack is a guide for the whole team. It has drawings, size charts, and lists of materials. This guide helps everyone understand what to do. You see fewer mistakes and faster work. The finished knitwear looks just like the first idea and can be changed for different brands or buyers.

Pattern Creation

Pattern creation is a big step in making knitwear. Designers use both hand-drawn and computer methods to make patterns for each dress. These patterns decide how the dress will look and fit. Special software helps you change sizes for different people, so every dress fits well.

Digital pattern grading helps save up to 15% of fabric in some places.

Good sketches and patterns help stop mistakes during production.

You save time and money, and the knitwear is better.

The team uses computers to plan every stitch. This is important for designer knitwear, where style and changes matter. The pattern must match the dress, whether it is a knit maxi dress or a fitted dress with sleeves. The team checks the pattern to make sure it is right for the style, fit, and changes needed.

The factory follows clear steps to make knitwear. Industry reports say the steps are:

1. Design and pattern making: You draw and plan each style. 2. Cutting: You cut the fabric or yarn using the patterns. 3. Sewing or linking: You put the pieces together by machine or hand. 4. Finishing: You add buttons or trims and check the quality. 5. Quality control: You look at each piece to make sure it is good. 6. Packaging and shipping: You get the knitwear ready to send out.

This way of working helps you make great knitwear with fewer mistakes. You can offer more choices and special designs. You also help the planet by wasting less and working better.

Tip: If you focus on pattern creation and working together, your knitwear will look better and last longer. You can also make it fit each customer just right.

Yarn and Material Selection

Choosing Quality Yarn

Every knitted dress starts with picking the right yarn. The yarn you pick changes how the dress feels and lasts. Some yarns are thick, so the dress is warmer and stronger. Thin yarns make the dress soft and smooth. Factories use both natural and man-made yarns for different needs.

Here is a table that shows how yarn properties affect knitwear:

Parameter | Impact on Knitwear |

|---|---|

Yarn Linear Density | Changes heat resistance, texture, and durability |

Yarn Hairiness | Affects insulation and fabric feel |

Fabric Thickness | Improves insulation and texture |

Mass per Unit Area | Increases durability and texture |

The way yarn goes in the dress changes how it stretches and holds up. Warp knitting uses yarns that go up and down. This makes the dress strong and steady. Weft knitting uses yarns that go side to side. This makes the dress stretch more.

Aspect | Warp Knitting (Vertical) | Weft Knitting (Horizontal) |

|---|---|---|

Moderate | High | |

Fabric Stability | High | Lower |

Durability | Higher | Lower |

Factories now care about the planet. They use yarns made from recycled things, organic cotton, bamboo, or seaweed. These choices help the earth and cut down on waste. Many brands want dresses that last and feel nice. You can pick new yarns that are comfy, work well, and are good for nature.

Material Testing

Factories must test yarn and materials before making dresses. They check for strength, color, and softness. They use rules like ISO, ASTM, and AATCC. Tests look at rubbing, pilling, washing, and color in light. Machines and sensors check each batch of yarn. This makes sure the dresses are good and safe for the planet.

Tip: Always check for badges like OEKO-TEX® or GRS. These show the dress is safe and made the right way.

Testing helps you know the dress will last, stretch, and keep its color. Picking good yarn and testing it means your dress will look great and work well.

Knitwear Manufacturing Technology

Advanced Knitting Machines

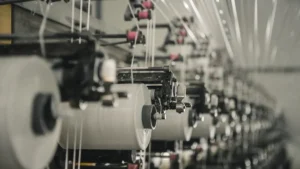

You see a big change in knitwear manufacturing when you use advanced knitting machines. These machines use computers to control every stitch. You can create complex patterns and shapes that are hard to make by hand. The machines read digital files from the design team. This means you can turn a new design into a finished dress quickly.

Factories use machines like the Shima Seiki WHOLEGARMENT® system. This machine knits a whole dress in one piece. You do not need to cut or sew panels together. This makes the dress stronger and more comfortable. You also save time and reduce mistakes. The machine can handle many types of yarn, from soft cotton to shiny metallic blends. You can switch between different yarns and patterns with just a few clicks.

Tip: When you use computerized machines, you can make knitwear with special textures, color blocks, or even 3D effects. You can also make small batches or test new ideas without wasting yarn.

Factories check the tension and thickness of the yarn before starting. This helps the machine knit each row evenly. You get a smooth finish and the right stretch in every dress. You can also use sensors to watch for yarn breaks or knots. This keeps the knitwear production line running smoothly.

3D and 4D Knitting

3D and 4D knitting are new ways to make knitwear. You use special machines that knit a dress in one piece, with no seams. This makes the dress fit better and feel softer on your skin. You do not need to sew panels together, so you save time and yarn. You also cut down on waste because you do not have leftover scraps.

3D knitting lets you make shapes and textures that are hard to sew. You can add pockets, ribbing, or even raised patterns right into the dress. You can also use different yarns in one dress, like mixing soft wool with shiny threads. This gives you more options for design and comfort.

4D knitting goes even further. You can change the shape or size of a dress after you make it. For example, the 4D Knit Dress from Ministry of Supply and MIT uses robotic knitting. You can alter or resize the dress after it leaves the factory. This means the dress lasts longer and fits more people. You help the planet by making less waste and using less yarn.

Startups like New Industrial Order use 3D knitting to make dresses that you can unravel and reuse. If you want a new style, you can take the dress apart and knit something new. This supports a circular economy and fights fast fashion waste. Digital 3D design software helps you see the dress before you make it. You can fix problems early and avoid making too many dresses.

Here is a table that shows some of the top innovations in knitwear manufacturing:

Technology / Innovation | Description | Benefits | Company / Event |

|---|---|---|---|

WHOLEGARMENT® knitting machines | Make seamless garments without cutting or sewing | Less waste, better fit, higher quality | Shima Seiki |

Seamless fabrics with special designs and elastane | No seams, less waste, stronger and easy to wash | Karl Mayer at ITMA 2023 | |

4D Knit Dress | One-piece dress with robotic finishing, can be resized | Almost no waste, can personalize, longer garment life | Ministry of Supply with MIT Self Lab |

3D Knitwear production | Clothes made in one piece, yarn can be reused | Circular economy, less fast fashion waste | New Industrial Order startup |

Digital 3D design software | Shows garments before making them | Less overproduction, less fabric waste | Used by many factories |

Note: 3D and 4D knitting help you make knitwear that is better for the planet. You use less yarn, make less waste, and can even reuse old dresses. You also get more comfort and style in every piece.

When you use these new machines and methods, you change how knitwear manufacturing works. You can make dresses faster, with fewer mistakes, and with less waste. You can also try new designs and yarns without big risks. This helps you keep up with trends and give customers what they want.

Assembly and Finishing

Panel Linking

The assembly step is where knitwear really comes together. After knitting, workers join the panels to make a dress. Factories use special machines to link each piece. This keeps the knitwear stretchy and comfy. The seams feel smooth and soft on your skin. Linking also helps the dress keep its shape and fit.

Factories sometimes use different yarn for linking. This yarn matches the main fabric’s color and stretch. You can pick from many options at this step. Some brands want seams that stand out. Others want seams you can barely see. You can even choose yarns that are extra strong or shiny. Customizing lets you make knitwear that is special for you.

Tip: If the panels are linked well, your dress will last longer and keep its shape after many wears.

Final Touches

Finishing steps make your knitwear look and feel great. Workers cut off loose threads and check every seam. They shape each dress with steam or heat to set the size. This helps the dress keep its form and fit.

You can add special touches here. Pick embroidery, buttons, or digital prints. Factories offer these details to match your style. You can also choose finishes to make the fabric softer or stop stains. Some dresses get singeing to remove loose fibers and stop pilling.

Quality checks happen all the time. Workers check seams and hems, test the dress after washing, and do a final check before packing. Here is a table showing important checkpoints:

Quality Control Checkpoint | Purpose | Importance for Final Product Quality |

|---|---|---|

Linking and Hemming Checks | Check seams and edges | Makes the dress look better and last longer |

Wet Processing Checks | Test after washing and finishing | Checks for shrinking and color changes |

Final Quality Check | Check finished dress before packing | Makes sure only good dresses are shipped |

You get knitwear that meets high standards because every detail is checked. Factories use digital tracking and follow ISO 9001 rules. This makes sure your knitwear is strong, colorful, and ready for any custom details you want.

Quality Control in Knit Dresses

Inspection Standards

You see the real value of knitwear when you look at the inspection process. Every step in the factory focuses on finding and fixing problems early. You check for holes, loose loops, uneven stitches, and color issues. You also look at the fit and how the dress feels. Meticulous craftsmanship means you pay attention to every detail, from the way the yarn sits to the way the seams hold together.

Factories use strict quality control standards. You follow a checklist for each knitwear piece. This checklist covers fabric strength, color, stretch, and even the smallest flaw. You use tools like magnifiers and light boxes to spot tiny defects. You also test the fabric by stretching and washing it. If you find a problem, you fix it before the dress moves to the next step.

Studies show that stitch length can change the number of defects in knitwear. If you do not control the process, you get more holes, knots, or loose threads. You use ABC analysis to focus on the most common problems. This saves time and helps you use your team wisely. You make sure each dress meets high quality before it leaves the factory.

Ensuring Consistency

You want every knitwear dress to look and feel the same. Factories use several ways to keep quality high and fit perfect:

You check sewing and linking often. This helps you catch mistakes early.

The Traffic Light System helps you see problems fast:

Red Board: More than half the dresses have defects. You stop and fix the issue.

Yellow Board: More than 10% have defects. You watch closely and improve.

Green Board: No defects. You reward good work.

You test fabric for fiber content, weight, and shrinkage. This keeps knitwear consistent.

You check seams for strength and even stitches. This keeps the dress strong and neat.

You use 3D body scans and random checks to make sure the fit is right for everyone.

You follow ISO 9001 rules to keep your quality check system strong.

You see that quality control is not just about finding mistakes. It is about making sure every piece of knitwear shows true craftsmanship. When you follow these steps, you get dresses that last, fit well, and make customers happy.

You can see how every part of making knitwear changes the dress. Designers use old ways and new tools to make special looks. Modern machines and skilled workers help make soft, nice-fitting knitwear. Some new companies mix 3D knitting with classic styles, so the clothes last longer. When you pick designer knitwear, you help the planet and choose styles that never go out of fashion. This mix of new ideas and classic looks keeps knitwear popular in designer clothes.

New companies use tech to give more choices and help skilled makers.

Brands mix old styles with new ideas for eco-friendly fashion.

Custom looks and classic designs make knitwear loved in fashion.

Notice the hard work, style, and new ideas in every knitwear piece. When you wear a designer knitwear dress, you wear something classic and creative.

FAQ

What makes factory-made knit dresses different from handmade ones?

Factory-made knit dresses have the same quality every time. Machines use exact patterns, so each dress fits the same way. Factories pick strong yarns and test each dress for color and strength.

How do factories keep knit dresses from pilling or losing shape?

Factories use machines like the ICI Pilling Box to test yarns. They pick anti-pilling fibers and check stretch with ASTM D2594. This helps dresses stay smooth and keep their shape after washing.

Can you order custom colors or styles for knit dresses?

Yes! Factories use Pantone® labs to match colors quickly. You can pick special yarns, add labels, or ask for your own designs. Most factories offer private-label services and can finish custom orders in about 10 days.

Are factory-made knit dresses eco-friendly?

Many factories use recycled yarns and renewable energy. They also track where materials come from. Look for badges like OEKO-TEX® or GRS. Choosing these dresses helps the planet.

1 thought on “Engineering Style in Stitches: How a Professional Factory Creates the Ultimate Knitted Dress and Knit Maxi Dress”

Pingback: A Factory-Level Guide to Producing High-Quality Knitted Dresses and Knit Maxi Dresses