Choosing the Right Knitwear Manufacturer is crucial. The right partner ensures top-notch quality, builds customer trust, and keeps you competitive. On the other hand, a poor choice can lead to subpar products and damage your reputation. In today’s challenging markets and with outdated practices, it’s more important than ever to choose wisely.

Key Takeaways

Know what your brand needs before picking a knitwear maker. This helps you choose someone who matches your goals.

Set clear rules for quality. Think about materials, how items are made, and quality checks to keep your brand looking good.

Look into manufacturers carefully. Check online lists, go to trade shows, and ask for recommendations to find trusted partners.

Understand Your Brand’s Needs

Before working with knitwear manufacturers, know what your brand needs. This helps you find a manufacturer that matches your goals and supports your success.

Define Quality Standards for Your Brand

Quality is key to your brand’s image. Think about what your customers expect. Do they want fancy knitwear made from expensive materials or cheaper, strong options? Different manufacturers focus on different quality levels. Knowing your standards will help you choose wisely.

Here’s what to think about:

Material Selection: The yarn or fabric affects how your product feels, lasts, and costs. For example, organic cotton or cashmere is eco-friendly but costs more.

Production Methods: Some factories make knitwear sustainably, while others focus on speed and saving money.

Quality Management: Good manufacturers check their work carefully to avoid mistakes and keep products consistent.

Tip: Use measures like yield, first-time yield, and customer feedback to check quality.

KPI | What It Measures |

|---|---|

Yield | How well products match planned designs. |

Perfect Order Percentage | The number of orders shipped on time without damage or missing items. |

First Time Yield | Products made correctly the first time without needing fixes. |

Customer Satisfaction | Surveys showing if buyers are happy with your products. |

Set a Budget and Pricing Goals

Your budget decides which knitwear supplier you can afford. Wholesale suppliers often have good prices, but make sure their costs fit your plans.

Here’s how to plan:

Estimate Costs: Include material, production, shipping, and extra fees.

Balance Quality and Price: Better knitwear costs more. Decide if you’ll pay extra for high-end products or stick to cheaper ones.

Negotiate Terms: Talk about prices, minimum orders, and payment schedules with suppliers.

Note: Many factories struggle to balance quality, cost, and being eco-friendly. Be ready to discuss what matters most to you.

Assess Production Scale and Timelines

Knowing how much you need made and when is important. Whether you need a small batch or a big order, pick a manufacturer who can handle your needs.

Think about these things:

Production Capacity: Some factories make small batches, while others handle big orders.

Lead Times: Production time depends on design complexity and factory speed.

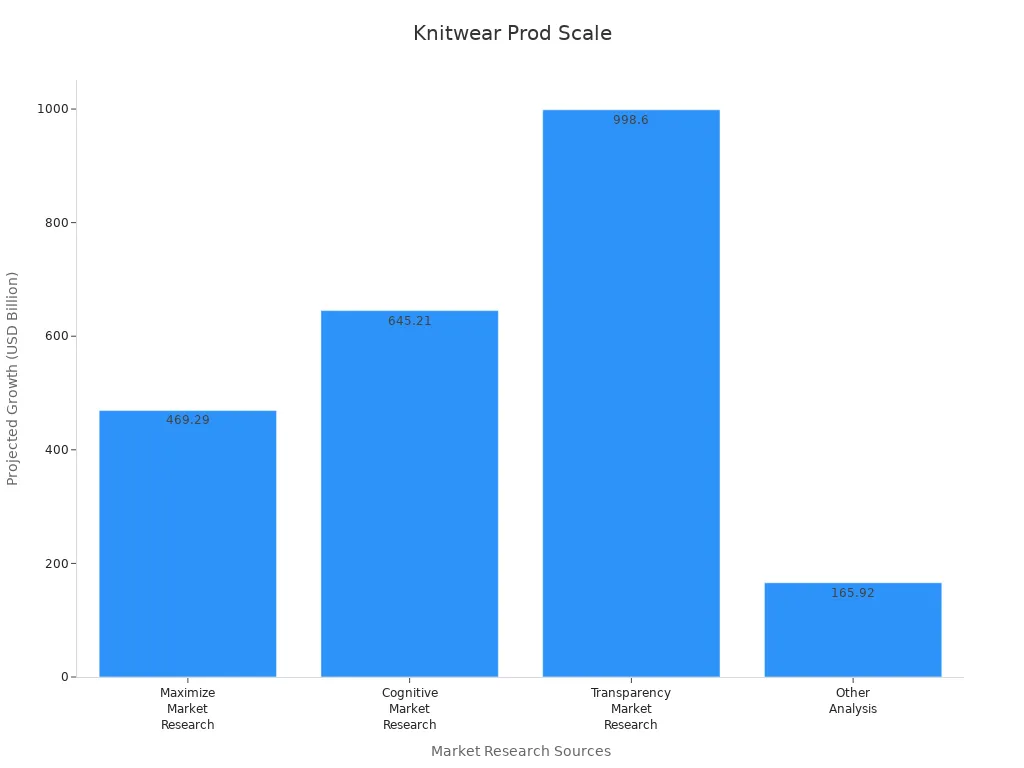

Market Trends: The knitwear market is growing fast, with billions expected by 2031. Factories are adjusting to meet demand.

Tip: Brands grow by using smart manufacturing, better inventory planning, and on-demand factories.

Strategy | What It Does |

|---|---|

Smart Manufacturing | Matches orders with production schedules to reduce waste. |

Inventory Optimization | Uses data to avoid leftover stock and plan better. |

Manufacturing Efficiencies | Cuts costs and boosts productivity with automation. |

On-demand factories | Makes small batches and custom items based on real-time demand. |

By knowing your brand’s needs, you can find a knitwear supplier who fits your goals and delivers great results.

Research Knitting Manufacturers

Finding good knitting manufacturers takes careful research. By checking different sources, you can find partners that match your brand’s goals. Here are three simple ways to begin your search.

Use Online Directories and Marketplaces

Websites with directories and marketplaces help you find manufacturers. Platforms like Alibaba, Makers Row, and Kompass list many knitting manufacturers. These sites show details like products, certifications, and customer reviews.

When using these tools, focus on important numbers to compare manufacturers:

Customer Acquisition Cost (CAC)

Customer Lifetime Value (CLTV)

Conversion Rate

Metric | What It Means |

|---|---|

Gross Merchandise Value | Total value of products sold on the platform. |

Customer Acquisition Cost | Money spent to get a new customer. |

Customer Lifetime Value | Profit expected from a customer over time. |

Conversion Rate | Percentage of users who take an action, like contacting a manufacturer. |

Tip: Pick manufacturers with good reviews and active customer engagement.

Attend Trade Shows and Networking Events

Trade shows and events are great for meeting manufacturers in person. Events like Premiere Vision or Texworld USA feature many suppliers, from small workshops to big factories. You can see samples, share your needs, and build connections.

Networking events also let you meet other brands and experts. These meetings can teach you about fabrics, production methods, and saving money. Meeting manufacturers face-to-face helps you judge their professionalism and dedication.

Pro Tip: Prepare questions about production size, delivery times, and eco-friendly practices.

Leverage Referrals and Industry Connections

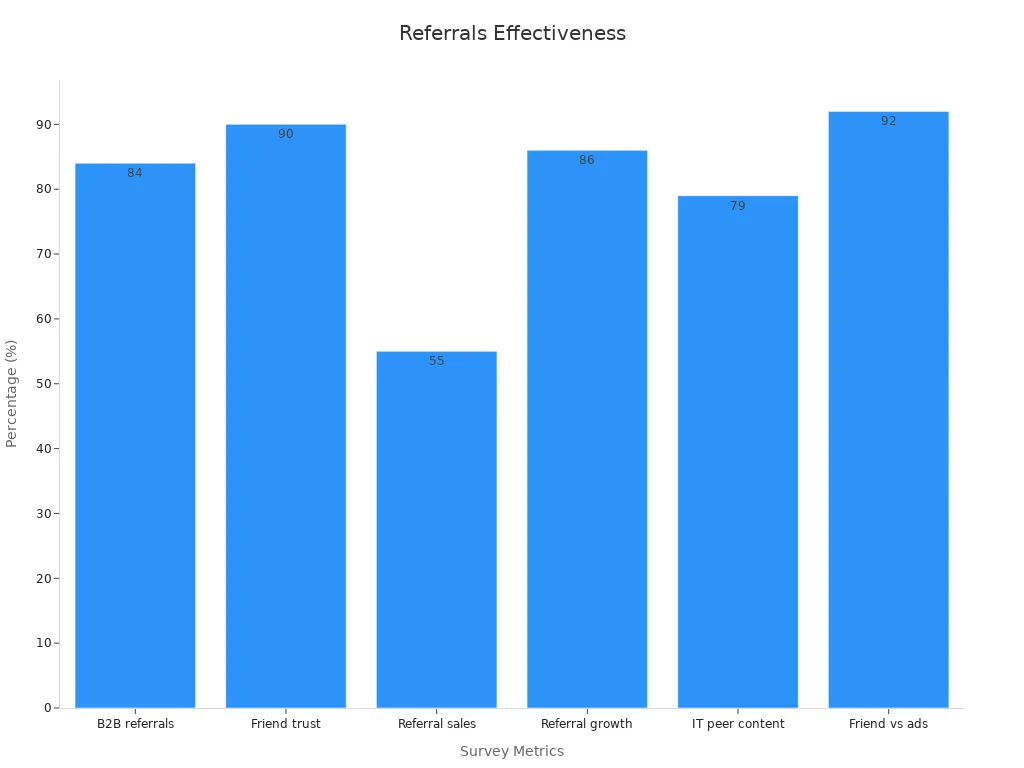

Referrals are a trusted way to find good knitting manufacturers. Many businesses start with referrals because they offer trust and reliability. For example, 84% of buyers say referrals are their first step in choosing a supplier.

Statistic | Source |

|---|---|

90% more likely to trust a brand recommended by a friend. | |

86% of B2B companies with referral programs experience growth. | |

55% of B2Bs with referral programs find their sales efforts highly effective. |

Ask people in your industry for suggestions about manufacturers they trust. Referrals often lead to reliable manufacturers with proven quality.

By using these three methods, you can find manufacturers that fit your brand’s needs.

Evaluate and Vet Potential Manufacturers

After picking a few clothing manufacturers, learn more about them. Checking and testing these partners helps you choose the best one for your brand. Follow these steps to do it right.

Ask for Samples and Check Quality

Always ask for product samples before choosing a manufacturer. Samples show their skill, fabric quality, and attention to detail. Good samples mean the knitwear manufacturer is reliable.

When checking samples, focus on these things:

Material Quality: Feel the fabric and check its strength.

Craftsmanship: Look for clean stitching and matching designs.

Longevity: Test the sample to see if it lasts over time.

Use this table to guide your sample checks:

Performance Metric | What It Shows |

|---|---|

Quality Control Measures | Products meet high standards every time. |

Testing Samples | Items stay strong in different situations. |

Quality Assurance Plan | Regular checks keep products consistent. |

Sample Evaluation | Shows how well the fabric and design match your needs. |

Tip: Don’t rely on just one sample. Ask for several to check consistency.

Verify Certifications and Compliance

Certifications prove a manufacturer follows ethical and safe practices. Look for certifications like GOTS or OEKO-TEX® to ensure they meet global standards.

Compliance Method | What It Does |

|---|---|

Third-party Certifications | Independent checks confirm the factory meets rules. |

Testing | Regular tests ensure products are safe and meet standards. |

Audits | Inspections find problems and improve processes. |

Chemical and Product Management Systems | Tracks chemicals and waste for better compliance. |

Certified manufacturers help your brand stand out. Customers like ethical knitwear, and working with certified factories builds trust.

Tip: Ask for proof of certifications before signing contracts.

Read Reviews and Testimonials

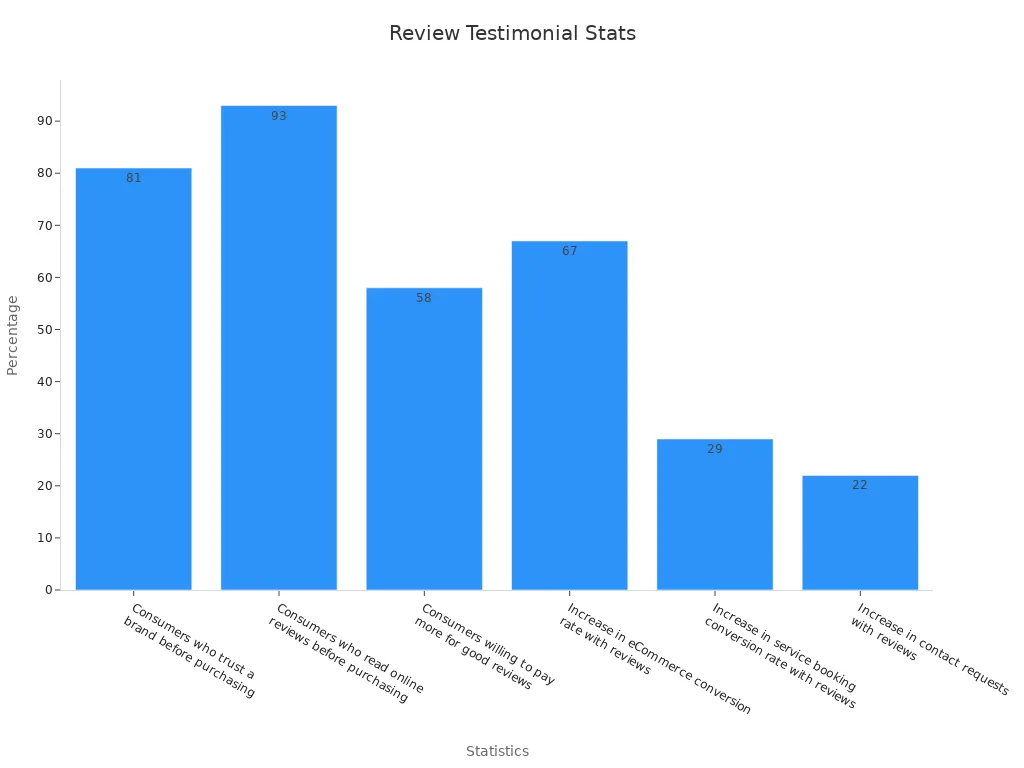

Reviews help you learn about other brands’ experiences with manufacturers. They show how reliable, skilled, and communicative the factory is. Reviews can uncover problems or highlight strengths.

Here are some review facts:

Statistic | Percentage |

|---|---|

People who trust a brand before buying | 81% |

People who read reviews before buying | 93% |

People willing to pay more for good reviews | 58% |

Higher eCommerce conversion rate with reviews | 67% |

Higher service booking rate with reviews | 29% |

More contact requests with reviews | 22% |

Look for common themes in reviews. Are there complaints about delays or poor quality? Or do most reviews praise fast delivery and great service? Testimonials from brands can also reveal helpful details.

Tip: Use third-party sites for honest reviews.

Test Communication and Responsiveness

Good communication makes partnerships successful. A knitwear manufacturer who answers quickly and clearly is more likely to meet your needs. Poor communication can cause problems and delays.

A study by Pinnacle shows how better communication helps:

Saved 30% on costs in one year.

Reduced suppliers by 75%.

Met all service agreements.

Why communication matters:

Better Relationships: Updates build trust and clarity.

Problem Prevention: Early fixes avoid big issues.

Cost Savings: Fixing problems early saves money.

Test how the manufacturer communicates. Do they reply fast? Are they open to solving your concerns? A good partner will value clear and timely communication.

Tip: Set up a call or meeting to check their professionalism.

By following these steps, you can pick the best clothing manufacturer for your brand. Careful checks ensure you work with someone who shares your goals and delivers great products.

Negotiate and Finalize Agreements

Talk About Pricing, MOQs, and Lead Times

When picking a manufacturer, discuss pricing, MOQs, and lead times. These three things affect your costs, timelines, and plans. Ask for a clear breakdown of their pricing. This shows what you’re paying for, like materials or shipping. If anything is unclear, ask questions to understand better.

MOQs, or minimum order quantities, are also important. Factories often need you to order a certain amount. If you’re new, find a supplier with low MOQs. This lets you start small without big risks. If you need more products, check if they can handle large orders on time.

Lead times matter too. Ask how long it takes to get your products. Things like production steps or busy seasons can cause delays. A good manufacturer will give clear timelines and stick to them. If you’re ordering from another country, check shipping times and costs early.

Tip: Use a checklist for pricing, MOQs, and lead times to compare suppliers.

Check and Sign Contracts

After agreeing on details, review the contract carefully. It should include pricing, delivery dates, and quality checks. Make sure it matches what you discussed. If something is unclear, ask for changes. Contracts should protect both you and the factory.

Look closely at rules about delivery times and late penalties. These help ensure your products arrive on time. Also, check for terms about ethical production if your brand values sustainability. If you’re designing custom knitwear, confirm the contract covers design rights and exclusivity.

Pro Tip: Have a lawyer review the contract before signing. This can prevent future problems.

Once everything is clear, sign the contract and keep a copy. Congrats—you now have a manufacturing partner!

Build a Long-Term Partnership

Working closely with your knitwear manufacturer helps keep quality steady. A good partnership helps both sides and supports your brand’s growth.

Set Up Clear Communication

Clear communication is important for a strong partnership. Share your needs and stay in regular contact with your manufacturer. First, check how you currently communicate to find any problems. Then, plan regular updates, like weekly calls or monthly emails. This builds trust and keeps things running smoothly.

Ways to improve communication:

Track how quickly they respond and how engaged they are.

Keep your messages short and easy to understand.

Talk openly to solve problems together.

Tip: Following up often shows you care about the partnership and their work.

Use Quality Control Steps

Quality checks protect your brand’s reputation. Work with your manufacturer to set clear rules for making knitwear. Test things like fabric strength, color fading, and stitching to ensure products meet your standards.

Focus on these areas:

Test if fabrics stay strong and colors don’t fade.

Check seams and stitches for neat and sturdy work.

Inspect products often to catch mistakes early.

These steps help reduce errors and keep customers happy with your products.

Work Together and Improve

Good partnerships grow through teamwork. Work with your manufacturer to adjust to market changes and improve processes. Be honest and open when sharing feedback, and ask them to do the same.

Strong partnerships grow over time. For example:

Caring about each other creates balanced relationships.

Adjusting to new challenges keeps the partnership useful.

Pro Tip: Treat your manufacturer like a partner, not just a supplier. This leads to better ideas and long-term success.

By focusing on communication, quality, and teamwork, you can build a partnership that helps your brand grow and delivers great results.

Picking the best knitwear manufacturer means knowing key steps. These include choosing materials, knitting, and checking quality. Research manufacturers to ensure they meet your quality and ethical needs. Clear communication builds trust and avoids confusion. Begin now—find a partner who shares your values and makes great products.

FAQ

How do I check production quality when picking a manufacturer?

Ask for samples to review fabric and stitching quality. Check how they make products to see if they meet your needs.

What makes a good clothing manufacturer?

Look for one using strong fabrics and fair practices. A good manufacturer ensures materials are high-quality and products are consistent.

Why does communication matter with a manufacturer?

Good communication avoids delays and reduces errors. It builds trust and helps keep product quality high during production.

18 thoughts on “How to Choose the Right Knitwear Manufacturer for Your Brand”

Pingback: A Complete Guide to Calculating Import Tax for Your Knitwear Shipments

Pingback: How to Choose the Right Shipping Method for Knitwear

Pingback: Engineering Style in Stitches: How a Professional Factory Creates the Ultimate Knitted Dress and Knit Maxi Dress

Pingback: Top 10 Knitted Hat Manufacturers for Bulk Orders in 2025

Pingback: Top Knitwear Manufacturers in Georgia for 2025 Rankings

Pingback: Why Choose the Top Knitting Manufacturer in Baltimore

Pingback: Top 10 Knitting Manufacturers in Cleveland for 2025

Pingback: Top Choices for Custom Knitwear Producers in Munich This Year

Pingback: Why Pintuck Knitwear is a Timeless Detail for High-End Fashion Buyers

Pingback: Pintuck Knit Pants: Comfortable Tailoring for Modern Women’s Fashion

Pingback: Luxury Fibers: A Comprehensive Guide to Luxury, Eco-Friendly & Budget Fibers for B2B Knitwear Sourcing

Pingback: Knitwear Construction: Seam Types, Techniques & Finishing for Professional Garment Production

Pingback: Mohair Best-Seller: How Mohair Becomes a B2B Best-Seller in Knitwear Manufacturing

Pingback: Meet the Manufacturers of St. John Knits

Pingback: Top 5 Knitting Manufacturers Making Waves in Tallaght

Pingback: Hanover’s Best Knit Apparel Manufacturers for Your Brand

Pingback: Best Knit Garment Manufacturers to Know in Genoa

Pingback: Top Knitting Manufacturer Picks in Segrate for Quality and Innovation